Cutting-Edge Automotive Parts for Electric Vehicle Integration

The switch to electric vehicles around the world has changed the way car parts are made. Electric vehicles are expected to make up more than 30% of all cars sold in the world by 2030. As a result, makers are having a harder time than ever finding the right parts. Aftermarket auto parts made to work with electric vehicles are very different from automotic parts; they need high-tech materials, precise engineering, and the ability to handle heat. It's hard for procurement managers to find reliable suppliers that can make custom plastic molds, die-casting parts, and precision-manufactured parts that meet strict EV performance standards while also staying cost-effective and protecting intellectual property.

Understanding Automotive Parts in Electric Vehicles

Component Categories and Their Distinct Roles

Electric vehicles need a completely different set of parts than vehicles with internal combustion engines. EVs' auto parts can be broken down into three main groups that work together to improve speed and fuel economy. Structures, suspension systems, and brake systems that have been modified to be renewable are examples of mechanical components. Electrical parts include power distribution units, wire leads, and plugs that safely handle high-voltage tasks. Control modules, sensors, and communication networks are all part of electronic systems that carefully run vehicles. What makes EV parts different from regular auto parts? The answer lies in what they need to do their job. For battery cases, the structure needs to be very rigid while also being very light. This is usually achieved through advanced plastic molding or metal die casting. Thermal control housings need materials that can get rid of heat quickly and keep their shape even when temperatures change. Power electronics cases need to block electromagnetic waves and support complicated shapes so that air can flow freely and cool devices effectively.

Critical Components for EV Integration Success

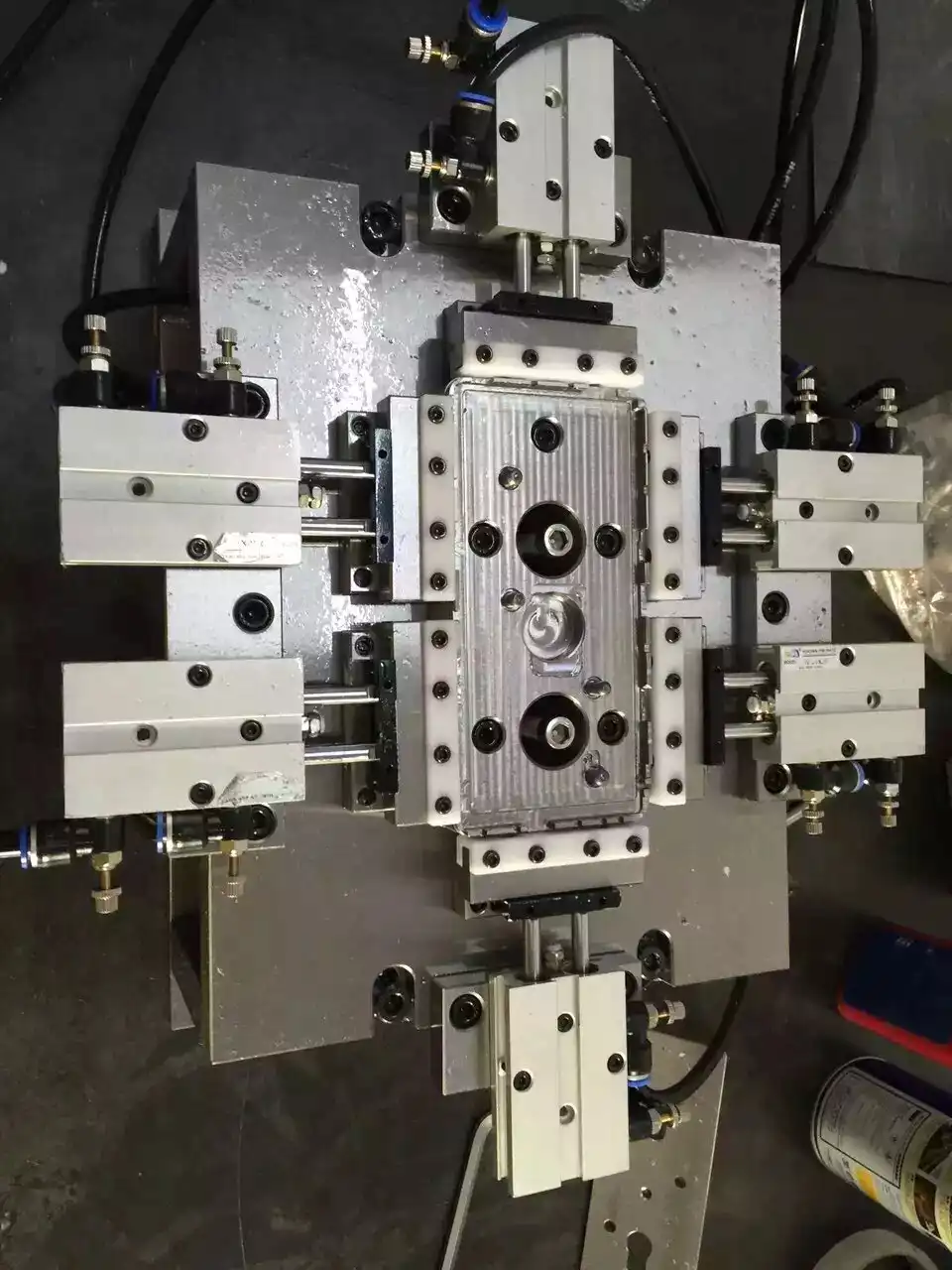

Battery management systems are the brains of electric cars. They need carefully made housings that keep sensitive circuits safe from heat, pressure, and wetness. A lot of the time, these cases have mounting clamps, wire handling channels, and heat contact surfaces that were made using multi-cavity injection molding. You can't say enough about how important housing design is to battery performance—even small changes in size can make it harder for heat to flow or cause problems with assembly later on. Making electric motors and automotic parts is tricky, but we've found ways to make them using special die-casting techniques. Motor housings need to be strong while also being light. This is done by using the right metal alloys and wall thickness variations. Incorporating a cooling jacket into these housings needs advanced mold design skills to make sure the coolant flows properly without affecting the structure performance. Our 20 years of experience making precise molds have given us the skills to make these complicated shapes. The thermal control parts need extra attention because they have a direct effect on the vehicle's range and the battery's life. Materials that stay stable at temperatures ranging from -40 to +85 degrees Celsius are needed for heat exchanger frames, water pipes, and air distribution housings. Our ISO9001:2015-certified methods make sure that the dimensions of each run of parts are the same, which is very important when these parts need to work with kits from different sources.

Essential Terminology for Procurement Professionals

Understanding the terms used in electric vehicles (EVs) makes it easier to talk to technical teams and providers. The secure housings that hold individual battery units and offer crash protection and heat separation are called battery pack enclosures. Power electronics inside inverter housings change DC battery power to AC current so that motors can run. For onboard charger assemblies, you need precision-molded parts that can handle high-voltage connections safely and get rid of the heat that builds up during charging cycles. More and more, procurement specifications include IP protection ratings, thermal conductivity coefficients, and material certifications that are specific to electrical applications in cars. As a board member of the Dongguan City Hardware Machinery Mould Industry Association, we stay up to date on changing standards and best practices and work closely with clients to turn these technical requirements into designs that can be made.

Comparative Analysis of Automotive Parts for Electric Vehicles

OEM Versus Aftermarket Components

Choosing between OEM and custom parts has a big effect on how much upkeep costs and how reliable something is in the long run. OEM parts are guaranteed to work with other parts and usually come with a full protection, which lowers the risk for fleet owners who are in charge of many cars. However, secondary choices are often more cost-effective, especially when large production numbers allow for economies of scale through specialized makers like our plant in Dongguan. These options have very different performance qualities. OEM parts go through a lot of certification testing in full car systems to make sure they work well together in a variety of situations. Aftermarket makers can give the same or better performance if they have a lot of experience in the field and strict quality control procedures. Because we've made parts for electronics, consumer goods, and cars before, we can meet OEM-equivalent standards and offer lower prices thanks to our central location near Shenzhen's transportation infrastructure and improved manufacturing processes.

Material Innovations Driving Durability

In the past few years, advanced industrial plastics have changed the way EV and automotic parts are made. For structural battery pack parts, glass-filled nylons have great strength-to-weight ratios, and tweaked polyphenylene sulfide materials have the chemical protection and physical stability needed for under-hood uses. We keep our skills up to date across all of these material groups, choosing the best formulas based on the needs of the product and the setting in which it will be used. Metal alloy development is similar to plastic innovation. Aluminum-silicon die-cast alloys can make thin-walled sections that are needed for motor housings that are light, and they can keep their mechanical properties even when heated and cooled many times. Magnesium metals can be used to make non-structural shelters even lighter, but they need to be handled in a certain way during production. Our 6,000-square-meter building has tools specifically designed to work with both aluminum and magnesium. This gives us the freedom to choose the material that best meets the needs of all of our clients.

Electric Versus Mechanical Component Integration

When combining electric motor parts with mechanical systems that come from traditional car designs, compatibility issues appear. Standardization of mounting interfaces is still not complete across the industry, so unique bracket designs and connector parts are needed. Our one-stop OEM service model helps us deal with these problems by working with clients from the beginning of the planning process all the way through production to make sure that all the parts fit together perfectly. Isolation from vibration is another important factor to think about. Electric motors and internal combustion engines produce different shaking patterns, so mounting systems need to be rebuilt to have the right dampening properties. Our engineering team works with clients to create custom rubber parts and the best-fitting shapes that keep the vehicle's positional accuracy and reduce vibration transfer over its entire operating life.

Optimizing Procurement Strategies for EV Automotive Parts

Selection Criteria That Ensure Quality and Continuity

Supplier certification represents the foundation of risk-managed procurement. ISO9001:2015 certification demonstrates commitment to quality management systems, though EV applications increasingly require additional certifications such as IATF16949 for automotive-specific processes. Our facility maintains these certifications alongside documented processes for intellectual property protection, addressing key concerns procurement managers face when working with overseas manufacturing partners. Lead time considerations deserve careful evaluation during supplier selection. Our location in Chang'an Town, known as the "Town of Molds," provides access to extensive supply networks for raw materials and specialized tooling components. This geographic advantage enables us to maintain lead times competitive with domestic suppliers while offering cost structures that improve project economics. We've consistently delivered mold fabrication within 4-6 week timeframes and transitioned to full production within 8-10 weeks from design freeze, supporting aggressive product development schedules. Warranty policies and quality assurance protocols vary significantly across suppliers. We provide comprehensive documentation throughout the manufacturing process, from material certifications through dimensional inspection reports and performance validation data. This transparency enables clients to maintain traceability requirements while building confidence in long-term supply relationships. Our approach to protecting client information extends beyond contractual obligations—we view IP protection as fundamental to maintaining trust relationships that span multiple product generations.

Cost Optimization Through Strategic Purchasing

Wholesale and bulk purchasing strategies deliver substantial value when implemented thoughtfully. Volume commitments enable amortization of tooling investments across larger production runs, reducing per-piece costs significantly. We work with clients to structure orders that balance inventory carrying costs against unit price reductions, often recommending phased delivery schedules that align with assembly line requirements while capturing volume pricing advantages. Secondary processing integration presents another cost optimization opportunity often overlooked during initial procurement planning. Components requiring post-molding operations such as machining, assembly, or surface treatmen,t benefit from consolidated manufacturing where a single supplier manages the complete process. Our facility provides CNC machining, ultrasonic welding, and various finishing operations in-house, eliminating transportation costs and coordination overhead while improving quality control through single-source accountability.

Modern Procurement Channels and Logistics Advantages

Digital procurement platforms have transformed how buyers discover and evaluate suppliers, though they cannot fully replace relationship-based partnerships for complex manufacturing requirements. We maintain online presence while emphasizing direct communication channels that facilitate technical discussions and collaborative problem-solving. Our proximity to Shenzhen Airport—just 50 minutes from our facility—enables convenient site visits where procurement teams can evaluate capabilities directly and establish personal relationships that support long-term collaboration. Logistics efficiency impactsthe total cost of ownership substantially. We coordinate with freight forwarders experienced in automotive parts transportation, ensuring proper packaging and handling throughout the supply chain. Our experience shipping to North American and European markets includes navigating customs requirements, managing documentation, and optimizing container utilization to minimize freight costs. These operational competencies complement our manufacturing expertise, delivering comprehensive value that extends beyond component quality alone.

Innovations Driving the Future of EV Automotive Parts

Smart Technologies and Connected Systems

Integration of sensor technologies within structural components represents an emerging frontier in automotive parts development. Battery enclosures increasingly incorporate temperature sensors, humidity monitors, and strain gauges that provide real-time data to vehicle management systems. These embedded sensors require manufacturing processes that accommodate delicate electronics within robust mechanical structures, achieved through insert molding techniques and carefully controlled processing parameters. Artificial intelligence applications extend beyond vehicle operation into manufacturing processes themselves. Predictive maintenance algorithms analyze production data to optimize mold maintenance schedules, reducing unplanned downtime and ensuring consistent part quality. We've implemented data collection systems throughout our facility that enable statistical process control and continuous improvement initiatives, positioning our operations to support clients requiring Industry 4.0 compatible supply chains.

Sustainability Initiatives in Materials and Processes

Environmental considerations increasingly influence material selection and manufacturing approaches for automotive parts. Recycled content plastics have matured to the point where they meet automotive performance requirements while reducing the carbon footprint associated with virgin resin production. We maintain capabilities to process both virgin and recycled materials for automotive parts, working with clients to identify opportunities where recycled content supports sustainability goals without compromising performance specifications. Circular economy principles extend to mold design and manufacturing processes for automotive parts. Designing components for disassembly and material separation at end-of-life enables higher recycling rates, particularly important as the first generation of mass-market electric vehicles approaches retirement. Our design collaboration services for automotive parts include end-of-life considerations, helping clients meet extended producer responsibility requirements while optimizing manufacturing costs and performance characteristics.

Market Evolution and Strategic Adaptation

Industry forecasts anticipate continued growth in EV component demand through 2035, driven by regulatory mandates and improving total cost of ownership relative to conventional vehicles. Procurement strategies must adapt to this expanding market by establishing flexible supply relationships capable of scaling with demand fluctuations. Our manufacturing capacity supports growth trajectories through modular expansion capabilities—we can add cavity positions to existing molds or develop parallel tooling to increase output without compromising quality or extending lead times. Technology convergence between the automotive and consumer electronics sectors creates opportunities for suppliers with cross-industry experience. Our client base spanning electronics, consumer goods, and automotive applications provides insights into emerging technologies and manufacturing techniques that transfer across industries. This diverse exposure enables us to bring innovative solutions to automotive clients, whether adapting surface finishing techniques from consumer electronics or applying automotive-grade quality systems to other product categories.

Conclusion

The electric vehicle revolution demands manufacturing partners who combine traditional precision with innovative capabilities addressing unique EV requirements. Automotive parts for electric vehicle integration require expertise spanning advanced materials, thermal management, and complex geometries that challenge conventional manufacturing approaches. Successful procurement strategies emphasize supplier relationships built on transparency, technical competence, and shared commitment to quality excellence. As the industry continues evolving toward smarter, more sustainable solutions, partnering with experienced manufacturers positioned at the intersection of automotive and electronics expertise delivers competitive advantages that extend throughout product lifecycles and across multiple vehicle generations.

FAQ

What distinguishes OEM parts from aftermarket alternatives for electric vehicle applications?

OEM components undergo validation testing within complete vehicle systems, ensuring compatibility and typically including manufacturer warranty coverage. Aftermarket parts can deliver equivalent performance when produced by manufacturers with appropriate certifications and quality control processes. Cost considerations often favor aftermarket options, particularly when suppliers possess specialized expertise and can optimize designs specifically for manufacturing efficiency without compromising performance specifications.

How can procurement managers verify supplier quality and reliability for EV component manufacturing?

Certification verification represents the starting point—ISO9001:2015 and IATF16949 certifications demonstrate systematic quality management and automotive-specific process controls. Facility visits provide direct assessment of equipment capabilities, cleanliness standards, and organizational culture. Reference checks with existing clients offer insights into delivery performance, responsiveness, and problem-solving capabilities. Documentation review, including material certifications, inspection reports, and process control data, reveals the depth of quality assurance practices beyond certifications alone.

What lead times should buyers expect for custom plastic molds and die-casting tooling?

Mold fabrication timelines depend on complexity, size, and cavity count. Single-cavity prototype molds typically require 4-6 weeks from design approval, while multi-cavity production tooling may extend to 8-12 weeks for complex geometries. Die-casting molds generally require 6-10 weeks, depending on size and feature complexity. Production launch adds 2-4 weeks for sampling, validation, and process optimization. Experienced manufacturers provide realistic schedules with milestone tracking that enables proactive planning and resource allocation.

How do manufacturers protect intellectual property for custom-designed components?

Comprehensive IP protection combines contractual agreements, physical security measures, and organizational policies. Non-disclosure agreements establish legal frameworks, while facility access controls limit exposure to proprietary designs. Digital security measures, including network segmentation and access logging, protect CAD files and technical documentation. Employee training and organizational culture development emphasize the importance. Reputable manufacturers view IP protection as fundamental to maintaining client trust rather than simply a contractual obligation.

Partner with Yongsheng for Your EV Automotive Parts Needs

Yongsheng stands ready to support your electric vehicle component requirements with comprehensive manufacturing capabilities refined over three decades. Our expertise as a specialized automotive parts supplier encompasses custom plastic mold design, precision die-casting, and complete production services that address the unique challenges of EV integration. We invite you to contact our team at sales@alwinasia.com to discuss your specific project requirements, request detailed capability documentation, or arrange a facility visit to our Dongguan location. Whether you need prototype development, tooling fabrication, or full-scale production support, our commitment to quality, IP protection, and on-time delivery ensures a partnership that advances your electrification objectives efficiently and cost-effectively.

References

1. International Energy Agency (2023). Global EV Outlook 2023: Catching up with climate ambitions. IEA Publications, Paris.

2. Society of Automotive Engineers (2022). Material Selection Guidelines for Electric Vehicle Battery Enclosures. SAE International Standards, Warrendale, Pennsylvania.

3. McKinsey & Company (2023). The future of automotive supplier collaboration in the EV era. McKinsey Quarterly Review, Automotive & Assembly Practice.

4. Roland Berger Strategy Consultants (2022). Advanced materials in electric vehicle lightweighting: Market analysis and procurement strategies. Roland Berger Publications, Munich.

5. Automotive Industry Action Group (2023). Quality Management System Requirements for Automotive Production and Service Parts Organizations: IATF 16949:2016 Implementation Guide. AIAG Publications, Southfield, Michigan.

6. Deloitte Center for Automotive Research (2023). Electric vehicle component supply chains: Risk assessment and supplier selection frameworks. Deloitte Development LLC, Detroit.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer