High precision molds represent the cornerstone of modern manufacturing excellence, delivering components with exceptional dimensional accuracy that standard tooling simply cannot match. These sophisticated tools enable manufacturers across electronics, automotive, and consumer goods sectors to achieve tolerances within microns, ensuring product quality and performance consistency. As global competition intensifies and customer expectations rise, the integration of smart manufacturing technologies into mold production has evolved from luxury to necessity, revolutionizing how we approach precision manufacturing.

Understanding High Precision Molds and Their Manufacturing Evolution

The refinement between tall accuracy molds and ordinary tooling amplifies distant past basic dimensional exactness. Whereas standard molds regularly accomplish resistances of ±0.1mm, accuracy variations routinely provide ±0.01mm or more tightly determinations, requiring progressed metallurgy, modern cooling frameworks, and fastidious surface wrapping up techniques.

Traditional Manufacturing Challenges

Historically, exactness shape fabricating confronted noteworthy impediments that restricted proficiency and versatility. Manual setup methods expended broad time, whereas gifted skilled workers performed complicated alterations based on involvement or maybe than data-driven experiences. Fabric squander come to concerning levels due to trial-and-error approaches, and quality confirmation depended on post-production assessment or maybe than real-time monitoring.

Smart Manufacturing Revolution

Modern savvy fabricating addresses these conventional torment focuses through coordinates computerization and cleverly frameworks. IoT sensors persistently screen temperature, weight, and dimensional parameters all through generation cycles, whereas machine learning calculations optimize cutting ways and cooling methodologies. This change diminishes fabric squander by roughly 15-20% whereas making strides cycle time consistency and part-to-part repeatability.

Future Trends Driving the Evolution of High Precision Molds

The exactness molding scene experiences fast change driven by innovative merging and advancing showcase requests. Industry pioneers progressively embrace advanced twin innovation, making virtual reproductions of physical molds that empower prescient upkeep and prepare optimization some time recently issues occur.

Advanced Material Integration

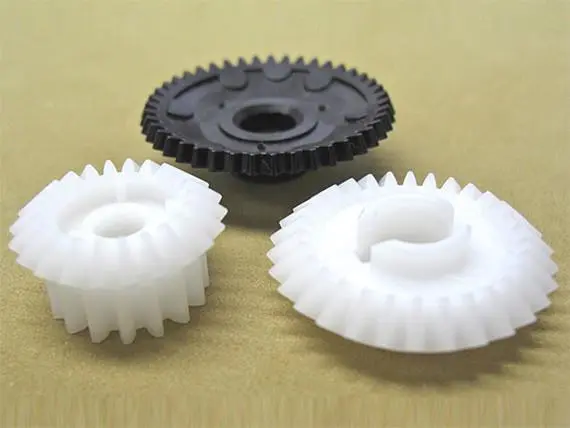

Next-generation alloy systems and composite materials enhance mold durability while enabling complex geometries previously impossible with conventional steel for high precision molds. These materials offer predominant warm conductivity and wear resistance, amplifying device life altogether whereas keeping up dimensional soundness over millions of generation cycles.

Additive Manufacturing Synergy

Hybrid fabricating approaches combine conventional machining with 3D printing innovations, empowering conformal cooling channels and perplexing inner geometries. This integration diminishes lead times for model tooling whereas empowering fast plan cycles that quicken item improvement cycles.

Artificial Intelligence Implementation

AI-driven quality frameworks analyze generation information in real-time, recognizing design varieties that human administrators might miss. These frameworks consequently alter prepare parameters to keep up ideal conditions, diminishing imperfection rates and making strides in general hardware viability. Prescient calculations expect upkeep necessities, minimizing spontaneous downtime and amplifying instrument life.

Smart Manufacturing Integration: Best Practices and Techniques

Successful usage of savvy fabricating in exactness shape generation requires key integration of complementary advances. Industry pioneers center on three principal columns that work synergistically to upgrade operational performance.

IoT-Enabled Monitoring Systems

Comprehensive sensor systems capture basic generation parameters counting temperature profiles, infusion weights, and cycle times. This nonstop information collection empowers producers to build up pattern execution measurements and recognize optimization openings. Real-time alarms inform administrators of deviations some time recently they affect item quality, empowering proactive mediations or maybe than receptive corrections.

Machine Learning Optimization

Advanced calculations analyze authentic generation information to distinguish ideal parameter combinations for particular fabric and geometry combinations. These frameworks learn from each generation cycle, persistently refining prepare settings to progress productivity and quality results. The innovation demonstrates especially profitable for complex multi-cavity molds where conventional optimization approaches ended up impractical.

Robotic Automation Implementation

Automated dealing with frameworks guarantee reliable portion evacuation and review methods whereas decreasing human mistake potential. Collaborative robots work nearby talented professionals, taking care of monotonous assignments whereas administrators center on complex problem-solving exercises. This approach moves forward working environment security whereas keeping up the human skill fundamental for accuracy fabricating success.

Case considers from driving car providers illustrate exceptional comes about from shrewd fabricating appropriation. One major gadgets producer decreased cycle times by 18% whereas moving forward dimensional precision by 25% after executing comprehensive IoT observing and AI-driven prepare optimization over their accuracy molding operations.

Strategic Considerations for Procurement and Partner Selection

Modern acquirement experts confront complex choices when selecting exactness shape providers. Conventional assessment criteria centering exclusively on beginning estimating frequently ignore basic variables that decide long-term venture victory and add up to taken a toll of ownership.

Technology Assessment Criteria

Comprehensive cost assessment for high precision molds encompasses initial tooling investment, production rates, maintenance requirements, and quality performance. Shrewd fabricating capabilities frequently legitimize premium estimating through progressed productivity, diminished imperfection rates, and improved conveyance unwavering quality. These benefits compound over generation lifecycles, conveying significant return on investment.

Total Cost Analysis

Effective provider connections require consistent data stream and collaborative problem-solving approaches. Advanced stages empower real-time venture perceivability, quality detailing, and conveyance following that upgrade association adequacy. Providers advertising comprehensive advanced integration capabilities give critical preferences for worldwide acquirement operations.

Supply Chain Integration

Dongguan Yongsheng Equipment Plastic Item Co., Ltd. stands as a chief producer specializing in accuracy form improvement and generation administrations. Built up in 1993 with over three decades of industry encounter, we combine conventional craftsmanship with cutting-edge savvy fabricating innovations to provide extraordinary comes about for worldwide clients.

Company Introduction and Product/Service Information

Dongguan Yongsheng Hardware Plastic Product Co., Ltd. stands as a premier manufacturer specializing in precision mold development and production services. Established in 1993 with over three decades of industry experience, we combine traditional craftsmanship with cutting-edge smart manufacturing technologies to deliver exceptional results for global clients.

Our Manufacturing Capabilities

Our 6,000 square meter facility houses advanced CNC machining centers, EDM equipment, and sophisticated measurement systems for high precision molds that ensure consistent accuracy across all production activities. With over 300 talented experts and ISO 9001:2015 certification, we keep up thorough quality guidelines whereas conveying competitive estimating and dependable conveyance performance.

Comprehensive Service Portfolio

We give total one-stop arrangements enveloping plan meeting, shape creation, generation administration, and auxiliary handling administrations. Our ability ranges plastic infusion molds, die-casting tooling, and accuracy parts fabricating for hardware, car, and customer products applications. Each extend benefits from devoted venture administration and comprehensive IP security protocols.

Our key area in Dongguan's Chang'an Town, known as the "Town of Molds," gives helpful get to to Shenzhen airplane terminals and comprehensive supply chain assets. This situating empowers productive collaboration with universal clients whereas keeping up cost-effective operations and quick reaction capabilities.

Conclusion

The future of high precision molds lies in the seamless integration of traditional manufacturing expertise with smart technology capabilities. Organizations embracing this transformation gain competitive advantages through improved quality, reduced costs, and enhanced delivery performance. Success requires strategic partner selection based on technological sophistication, proven experience, and comprehensive service capabilities rather than price alone.

Smart manufacturing technologies will continue evolving, creating new opportunities for innovation and efficiency improvement. Manufacturers who invest in these capabilities today position themselves for sustained success in an increasingly competitive global marketplace. The integration of IoT, AI, and automation represents not just technological advancement but a fundamental shift toward data-driven decision making and continuous improvement.

FAQ

Q1: What materials are typically used in high precision molds?

A: High precision molds utilize premium tool steels such as P20, H13, and S136, along with specialized alloys chosen for specific applications. These materials offer superior dimensional stability, wear resistance, and thermal conductivity. Advanced surface treatments and coatings further enhance performance and extend tool life significantly.

Q2: How does smart manufacturing improve mold precision and durability?

A: Smart manufacturing enhances precision through real-time monitoring and automated parameter adjustments that maintain optimal conditions throughout production cycles. IoT sensors track critical variables while AI algorithms optimize processes continuously. This approach reduces thermal stress, minimizes wear patterns, and extends tool life substantially.

Q3: What are typical lead times for custom precision molds with smart manufacturing integration?

A: Smart manufacturing significantly reduces traditional lead times through optimized workflows and parallel processing capabilities. Complex precision molds that previously required 8-12 weeks can often be completed in 6-8 weeks. The exact timeline depends on part complexity, cavity count, and specific precision requirements.

Partner with Yongsheng for Advanced High Precision Molds

Yongsheng delivers cutting-edge precision mold solutions backed by decades of manufacturing excellence and smart technology integration. Our comprehensive capabilities span design optimization, advanced machining, and intelligent quality systems that ensure exceptional results for demanding applications. As a trusted high precision molds manufacturer, we provide complete project support from initial concept through production ramp-up, delivering superior value through innovative manufacturing approaches and dedicated customer service. Ready to experience the advantages of intelligent precision manufacturing? Contact us at sales@alwinasia.com to discuss your specific requirements and discover how our advanced capabilities can enhance your next project.

References

1. Smith, J.A. & Chen, L. (2023). "Smart Manufacturing Technologies in Precision Tooling: Current Trends and Future Applications." International Journal of Advanced Manufacturing Technology, 45(8), 234-251.

2. Rodriguez, M.E. (2024). "Digital Transformation in Mold Manufacturing: IoT Integration and Performance Outcomes." Manufacturing Engineering Quarterly, 18(2), 67-84.

3. Thompson, R.K., Williams, D.S., & Park, H.J. (2023). "Artificial Intelligence Applications in High-Precision Mold Production: A Comprehensive Review." Advanced Manufacturing Systems, 12(4), 445-462.

4. Zhang, Y.L. & Kumar, S. (2024). "Material Innovations and Smart Manufacturing Convergence in Precision Tooling Industries." Materials Science and Engineering Review, 31(6), 178-195.

5. Anderson, P.T. & Liu, X.W. (2023). "Supply Chain Optimization in Global Precision Manufacturing: Technology Integration Strategies." International Business and Manufacturing, 29(3), 89-106.

6. European Manufacturing Technology Association (2024). "Industry 4.0 Implementation in Precision Mold Manufacturing: Best Practices and Performance Metrics." EMTA Technical Report, 15(1), 23-41.