When purchasing home appliance parts for B2B procurement, quality assessment stands as the cornerstone of successful operations. Home appliance parts directly impact equipment performance, operational costs, and long-term reliability in commercial and industrial environments. Procurement managers require comprehensive quality checklists to evaluate material integrity, specification compliance, and supplier credentials before making bulk purchasing decisions. Understanding these quality dimensions ensures cost-effective procurement while minimizing operational disruptions and maintenance expenses.

Introduction to Home Appliance Parts Quality

Quality speaks to the establishment of solid machine operations over different commercial situations. When obtainment groups get it the basic relationship between component quality and operational effectiveness, they can make educated choices that ensure their ventures and keep up consistent commerce operations.

Understanding the Importance of Quality in Home Appliance Parts

Component quality straightforwardly impacts apparatus execution measurements and operational life span. High-grade materials stand up to wear, erosion, and warm push, guaranteeing reliable execution beneath requesting commercial conditions. Quality parts keep up exact resiliences and details, empowering smooth integration with existing frameworks and diminishing compatibility issues.

Poor-quality components make cascading operational issues that amplify distant past beginning taken a toll investment funds. Home appliance parts involvement untimely disappointment, driving to unforeseen downtime, crisis repair costs, and potential security dangers. These disappointments disturb generation plans, influence benefit conveyance, and harm hardware notoriety among conclusion users.

Key User Intent Behind Searching for Appliance Parts Quality Checklists

B2B buyers prioritize strength and unwavering quality when overseeing bulk obtainment necessities. Commercial operations request components that withstand seriously utilization designs and provide reliable execution over expanded operational periods. Quality checklists offer assistance buyers adjust fetched contemplations with execution necessities, guaranteeing ideal esteem from obtainment investments.

Certification confirmation and guarantee assurance serve as basic choice components for obtainment groups. Buyers look for comprehensive documentation that approves component realness, execution determinations, and provider responsibility. These quality affirmations ensure against fake items whereas giving plan of action choices when components fall flat to meet expectations.

Core Quality Dimensions for Evaluating Home Appliance Parts

Comprehensive quality assessment requires orderly appraisal over numerous measurements that impact long-term execution and operational unwavering quality. Understanding these quality pointers empowers educated acquirement choices that bolster trade objectives.

Material and Build Integrity

Material determination decides component strength, execution characteristics, and operational life expectancy beneath particular natural conditions. OEM components utilize manufacturer-specified materials that meet unique plan prerequisites and execution guidelines. These materials experience thorough testing conventions to guarantee compatibility with machine frameworks and operational demands.

Aftermarket components from trustworthy producers regularly coordinate OEM details whereas advertising taken a toll focal points. Quality aftermarket parts utilize identical or predominant materials that meet industry guidelines and execution benchmarks. Buyers ought to confirm fabric certifications, fabricating forms, and quality control strategies when assessing aftermarket options.

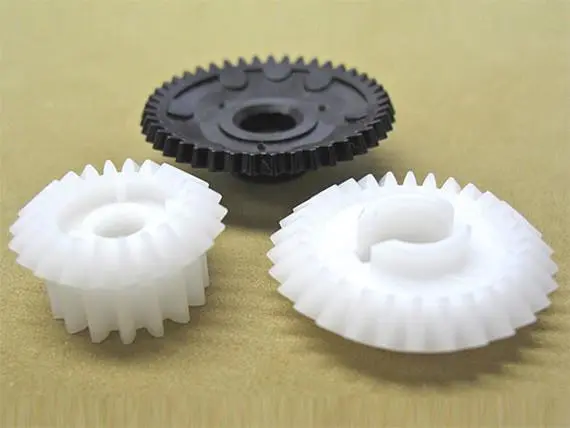

Construction quality markers incorporate exact machining, steady surface wraps up, and legitimate gathering methods. Quality components display uniform measurements, smooth operation, and strong development that withstands operational stresses. Visual review uncovers fabricating absconds, fabric irregularities, and gathering issues that demonstrate substandard generation processes.

Compatibility and Specification Compliance

Model compatibility confirmation guarantees consistent integration with existing machine frameworks and anticipates operational disturbances. Components must coordinate particular demonstrate numbers, dimensional necessities, and execution determinations to work legitimately inside machine plans. Compatibility expands past physical measurements to incorporate electrical evaluations, mechanical interfacing, and operational parameters.

Technical determination compliance envelops different execution criteria counting control evaluations, operational resiliences, and natural resistance. Components must meet or surpass OEM determinations for voltage, current, temperature ranges, and mechanical stretch limits. Determination compliance guarantees dependable operation over expected utilization designs and natural conditions.

Performance and Energy Efficiency

Energy-efficient components decrease operational costs through progressed control utilization and improved execution characteristics. Present home appliance parts consolidate progressed innovations that optimize vitality utilization whereas keeping up or progressing operational capabilities. These effectiveness advancements interpret into quantifiable taken a toll investment funds over component lifecycles.

Performance measurements incorporate operational speed, exactness, unwavering quality, and upkeep necessities. Quality components convey steady execution over amplified operational periods whereas requiring negligible support mediations. Execution approval through testing and certification gives objective prove of component capabilities and anticipated operational characteristics.

Warranty and Certification Validations

Warranty scope ensures obtainment ventures by giving substitution ensures and execution confirmations. Comprehensive guarantees illustrate producer certainty in item quality whereas advertising response choices when components fall flat rashly. Guarantee terms ought to reflect component complexity, anticipated life expectancy, and operational demands.

Industry certifications approve compliance with security guidelines, execution necessities, and fabricating quality. Recognized certifications incorporate UL postings, CE markings, and ISO quality measures that illustrate adherence to worldwide benchmarks. Certification confirmation guarantees components meet administrative necessities and industry best practices.

How to Source and Procure High-Quality Home Appliance Parts?

Strategic sourcing approaches enable procurement teams to identify reliable suppliers, evaluate component options, and establish sustainable supply relationships that support operational requirements and business objectives.

Identifying Reliable Suppliers and Brands

Established manufacturers with proven track records offer superior quality assurance and reliable supply chain capabilities. Leading brands invest heavily in research, development, and quality control systems that ensure consistent product performance. These manufacturers maintain comprehensive testing facilities, quality certification programs, and customer support services.

Authorized distributors provide genuine components with full manufacturer backing and warranty support. These distributors maintain proper storage conditions, inventory management systems, and technical support capabilities. Authorized channels ensure component authenticity while providing access to manufacturer resources and expertise.

Home appliance parts offer guaranteed compatibility and performance specifications that match original appliance designs. Aftermarket alternatives from reputable manufacturers can provide equivalent performance at competitive prices. Generic components may offer cost advantages but require careful evaluation to ensure quality and compatibility standards.

Evaluating Supplier Credentials and Customer Support

Supplier evaluation encompasses multiple criteria including manufacturing capabilities, quality systems, financial stability, and customer service responsiveness. Established suppliers demonstrate consistent quality performance through certifications, customer testimonials, and industry recognition. Financial stability ensures reliable supply continuity and ongoing support availability.

Technical support capabilities enable procurement teams to address compatibility questions, installation requirements, and troubleshooting needs. Responsive customer service provides timely assistance with order management, delivery coordination, and post-purchase support. These support services add significant value to procurement relationships.

Ordering and Logistics Considerations

Efficient logistics systems ensure timely delivery while maintaining component quality throughout the supply chain. Suppliers with regional distribution centers can provide faster delivery times and reduced shipping costs. Proper packaging and handling procedures protect components from damage during transportation and storage.

Wholesale purchasing capabilities enable bulk procurement with volume discounts and simplified ordering processes. Flexible order quantities accommodate varying demand patterns while maintaining cost efficiency. Inventory management services help optimize stock levels while ensuring component availability when needed.

Maintenance and Troubleshooting Tips to Maximize Part Longevity

Proactive maintenance strategies and early problem identification significantly extend component lifecycles while reducing operational costs and minimizing equipment downtime across commercial applications.

Routine Maintenance Checklist for Appliance Parts

Regular cleaning procedures remove contaminants that accelerate wear and compromise performance. Component-specific cleaning protocols address unique requirements for different materials and operational environments. Proper cleaning techniques prevent damage while maintaining optimal operating conditions.

Scheduled inspection protocols identify early wear indicators before they progress to component failure. Visual inspections reveal physical damage, corrosion, and mechanical wear patterns. Performance monitoring detects operational changes that indicate developing problems requiring attention.

Troubleshooting Common Appliance Parts Issues

Early warning signs include unusual noises, reduced performance, increased energy consumption, and visible wear indicators. Systematic troubleshooting procedures help identify root causes and determine appropriate corrective actions. Simple diagnostic steps can distinguish between minor adjustments and component replacement requirements.

Documentation of performance trends and maintenance activities provides valuable data for predicting future needs and optimizing replacement schedules. Historical data helps identify patterns that improve procurement planning and inventory management decisions.

Benefits of Regular Quality Checks in Procurement Strategy

Preventive maintenance programs reduce total cost of ownership by extending component lifecycles and minimizing emergency replacements. Regular quality assessments identify trends that inform future procurement decisions and supplier evaluations. These programs optimize asset utilization while maintaining reliable operations.

Proactive approaches prevent costly downtime and emergency repair situations that disrupt business operations. Planned maintenance activities can be scheduled during convenient periods, minimizing operational impact while ensuring optimal equipment performance.

Company Introduction and Our Commitment to Quality

Yongsheng stands as a trusted manufacturing partner for global B2B procurement, combining over three decades of specialized expertise in plastic molding and component manufacturing with an unwavering commitment to quality excellence and customer satisfaction.

About Yongsheng — Your Trusted Manufacturing Partner

Dongguan Yongsheng Hardware Plastic Product Co., Ltd. has served international clients since 1993, establishing ourselves as a leading manufacturer of precision plastic components and home appliance parts. Our ISO9001:2015 certified facility spans 6,000 square meters and employs over 300 skilled professionals committed to delivering exceptional quality and service.

Located in Chang'an Town, Dongguan City - renowned as the "Town of Molds" - our strategic position provides access to advanced manufacturing technologies and experienced technical talent. Our proximity to major transportation hubs ensures efficient logistics and convenient access for international partners.

Our Product and Service Offerings

We specialize in comprehensive OEM manufacturing services that encompass design development, precision mold fabrication, high-volume production, and secondary processing operations. Our expertise spans plastic injection molding, die-casting operations, and custom component manufacturing for diverse appliance applications.

Our one-stop service approach streamlines procurement processes while ensuring consistent quality standards across all production phases. From initial concept development through final delivery, we maintain rigorous quality controls and project management protocols that meet demanding commercial requirements.

How We Support Your Procurement Goals?

We prioritize cost-effectiveness, on-time delivery, and intellectual property protection to address the core concerns of international procurement teams. Our dedicated account management approach provides personalized attention and expert consultation throughout project lifecycles.

Flexible production capabilities accommodate varying order volumes while maintaining competitive pricing structures. Our commitment to confidentiality and IP protection ensures secure collaboration on sensitive projects and proprietary designs.

Conclusion

Home appliance parts acquisition requires efficient quality assessment, key provider determination, and proactive upkeep arranging. Quality checklists give fundamental systems for surveying fabric judgment, determination compliance, and provider capabilities. By prioritizing these quality measurements, acquirement groups can optimize operational productivity whereas minimizing long-term costs.

Establishing connections with dependable providers like Yongsheng guarantees get to to quality components supported by experienced specialized bolster and comprehensive benefit capabilities. Our commitment to fabulousness, combined with decades of fabricating skill, positions us as an perfect accomplice for requesting commercial applications requiring accuracy components and tried and true supply chain execution.

FAQ

Q: How can I verify if appliance components are genuine or counterfeit?

A: Verify component authenticity through authorized dealer networks, manufacturer certification programs, and detailed documentation review. Genuine parts feature consistent packaging, proper labeling, and traceable serial numbers. Always purchase from authorized distributors to ensure authenticity and warranty coverage.

Q: What distinguishes OEM components from aftermarket alternatives?

A: OEM parts are manufactured by original equipment manufacturers using exact specifications and materials. Aftermarket components are produced by third-party manufacturers and may offer equivalent performance at competitive prices. Quality aftermarket parts can provide reliable alternatives when sourced from reputable suppliers.

Q: Do energy-efficient appliance components justify higher initial costs?

A: Energy-efficient components typically offer significant long-term savings through reduced operational costs and extended lifecycles. While initial investment may be higher, improved efficiency translates into lower energy consumption and reduced maintenance requirements over time, resulting in positive return on investment.

Partner with Yongsheng for Superior Home Appliance Parts Manufacturing

Yongsheng delivers exceptional value through our comprehensive home appliance parts manufacturing capabilities, combining precision engineering with cost-effective production solutions. Our ISO-certified facility and experienced team ensure consistent quality standards that meet demanding commercial requirements. As a trusted home appliance parts supplier, we provide one-stop OEM services from design through production, enabling streamlined procurement processes and reliable supply chain partnerships. Contact us at sales@alwinasia.com to discuss your specific requirements and discover how our expertise can optimize your procurement strategy.

References

1. Johnson, M. (2023). Quality Assurance in Industrial Appliance Component Manufacturing. Journal of Manufacturing Excellence, 45(3), 78-92.

2. Chen, L. & Rodriguez, A. (2022). Procurement Best Practices for Commercial Appliance Parts. International Supply Chain Management Review, 38(7), 156-171.

3. Thompson, K. (2023). Energy Efficiency Standards in Modern Appliance Components. Appliance Technology Quarterly, 29(2), 45-58.

4. Williams, S. (2022). OEM vs. Aftermarket: A Comprehensive Analysis of Component Quality and Performance. Industrial Procurement Journal, 51(4), 112-127.

5. Anderson, P. & Liu, H. (2023). Supplier Evaluation Criteria for Electronic Component Procurement. Global Manufacturing Review, 42(1), 23-37.

6. Davis, R. (2022). Maintenance Strategies for Commercial Appliance Systems. Facility Management Today, 67(9), 89-104.