When it comes to home appliance parts, procurement managers have to make a tough choice: should they buy specialized parts or choose generic ones? This choice has a big effect on how well the product works, how reliable it is, and how happy customers are in the long run. When it comes to compatibility and durability, specialized home appliance parts are better than generic ones, but they usually cost more at first. Knowing the main differences between these choices helps you make smart buying decisions that fit your company's budget and quality standards.

Figuring out what the main differences are between generic and specialized parts

The main difference between generic components and parts for home appliances is how they were designed and how precisely they were made. Specialized parts are put through a lot of tests to make sure they work well with certain appliance models and conditions.

When you compare these choices, you can see three main differences:

- Precision Engineering: The exact size tolerances for specialized parts are ±0.02mm, while the exact size tolerances for generic parts are ±0.1mm.

- Material Specifications: Custom materials can handle certain chemical and temperature levels.

- Performance optimization: parts that are made to work as efficiently as possible within certain limits

Testing data from appliance makers shows that replacement parts made specifically for the appliance last 85% longer than generic alternatives. This performance gap is caused by carefully choosing the right materials and using manufacturing methods that are designed to work with certain products.

Even though they cost more up front, specialized home appliance parts are worth it in the long run if you need parts for large production runs. Generic parts work better for making prototypes or for short-term uses where saving money is the most important thing.

Durability and Reliability Metrics for Performance Analysis

Different types of performance testing show big differences between specialized and generic parts in many areas. Studies done in the lab make it clear that custom-made appliance repair parts are better in many ways.

This is what independent testing facilities say about the performance:

- Thermal cycling: specialized parts can handle 15,000 cycles, while generic parts can only handle 8,500.

- Load Bearing: Custom parts can handle 40% more stress loads before they break.

- Chemical Resistance: Parts that were made for harsh environments last three times longer before breaking down.

- Dimensional Stability: Over 10,000 hours of use, specialized parts keep tolerances within 0.1%.

Manufacturers of washing machines say that specialized parts cut down on service calls by 67% compared to generic ones. This increase in dependability directly leads to a better reputation for the brand and lower warranty costs.

Motor assemblies are another important thing to compare. When the same conditions are used, custom-engineered motor replacement units produce torque output that is consistent within a 2% range, while generic motors show 8–12% variation.

If you need products that people will use to be as reliable as possible, then specialized parts give you the best performance consistency. Generic options work well in situations where small differences in performance are okay within larger tolerance ranges.

Cost factors and a look at the long-term value

The most obvious difference between home appliance parts categories is the initial price. Generic spare parts are often 30–50% less expensive than specialized ones, which makes them appealing to buyers who are watching their budgets.

However, a full cost analysis shows that value propositions are complicated:

- Costs of Buying: Generic parts save you $2 to $15 per unit right away.

- Controlling quality: specialized parts cut inspection time by 60%

- Warranty claims: parts that are made just for the job cut warranty costs by 45%

- Inventory Management: Standardized parts make managing stock easier

According to data from the manufacturing industry, specialized refrigerator parts cause 40% fewer production line stops than generic alternatives. This better consistency cuts down on production delays and the costs of labor that come with them.

Total cost of ownership calculations over three years show that specialized parts provide 15–25% more value, even though they cost more at first. In places where a lot of things are made, this benefit stands out even more.

If you need stable production costs and little downtime, then the extra cost of specialized parts is worth it. Generic parts work better for projects that need to save money but don't have to meet strict quality standards.

Standards for quality control and manufacturing

Standardization in manufacturing makes a big difference between types of parts. Manufacturers of specialized parts for home appliances have more thorough quality control systems than manufacturers of generic parts.

Comparisons of quality control results show big differences:

- Inspection Protocols: Generic producers only do 4-point quality checks, while specialized manufacturers do 12 point checks.

- Material Traceability: Full tracking of a material's history lets problems be fixed quickly.

- Statistical Process Control: Monitoring in real time keeps quality of output stable

- Certification Compliance: Parts made for a specific purpose meet safety standards set by the industry

Manufacturers of appliances need dishwasher parts that have been approved by UL and CSA for safety. Specialized component suppliers keep these certifications up to date with regular tests and audits. Generic suppliers often don't have the same level of certification.

Control board assemblies show how different quality standards can be. Specialized boards go through protocols for accelerated aging, electromagnetic compatibility testing, and thermal shock testing. Usually, only basic functionality tests are done on generic boards.

Specialized component manufacturers have a 90% compliance rate with ISO 9001, while generic suppliers only have a 45% compliance rate. Implementing this quality system has a direct effect on how consistent the products are and how many defects there are.

Specialized parts give you the certification support you need for documented quality assurance and regulatory compliance. Generic options work well for uses with few regulatory requirements.

Reliability in the supply chain and strategies for sourcing

Supply chain issues have a big effect on decisions about where to get parts. Specialized suppliers of appliance parts usually keep larger stock levels and more stable delivery schedules.

Metrics for measuring the performance of the supply chain make clear differences:

- Delivery Performance: 96% of specialized suppliers deliver on time, while only 78% of generic suppliers do.

- Inventory Availability: Stock levels of purpose-built parts are about 85% full, while generic parts are only 62% full.

- Lead Time Consistency: specialized suppliers keep a ±2-day range, while generic sources keep a ±7-day range.

- Communication Responsiveness: Dedicated account management cuts the time it takes to solve problems by 60%

Specialized suppliers can more accurately predict demand for oven replacement parts and other similar parts when they work together with other manufacturers. This forecasting feature helps with better planning of inventory and fewer instances of running out of stock.

Strategies for reducing risk are very different between types of suppliers. Specialized manufacturers keep up with multiple production sites and backup systems for tools. Generic suppliers usually only use one source for production, so there isn't much redundancy.

Specialized suppliers offer better supply chain stability if you need to be sure of a steady supply and know when your deliveries will arrive. When cost savings and flexibility are more important than delivery consistency, generic sources work better.

Help with technology and application engineering

There are big differences in value between home appliance parts categories based on their technical support capabilities. Specialized suppliers of home appliance parts offer full engineering support throughout the entire product development cycle.

Comparing support services shows big gaps in their abilities:

- Help with design: Some suppliers have dedicated application engineers on staff.

- Support for Testing: Full validation services, including performance and environmental testing

- Documentation: Detailed technical specs and instructions for installation

- Training Programs: Getting procurement and engineering teams technical training

Getting engineering help from a supplier is a big help when making custom vacuum cleaner parts. Specialized manufacturers offer computational fluid dynamics analysis, help with choosing materials, and suggestions for improving performance.

When suppliers give detailed technical documentation and troubleshooting guides, appliance maintenance needs go down by a lot. Specialized suppliers put a lot of money into support materials that generic suppliers don't usually make.

Support for field applications is another important thing that sets us apart. Specialized suppliers keep technical teams on hand that can solve problems and improve performance on-site. Support from generic suppliers is usually limited to basic product information.

If you need a lot of technical help and engineering collaboration, specialized suppliers offer the best value because they offer a wide range of services. Generic suppliers work well for simple tasks that don't need much technical help.

Yongsheng's Pros in Making Parts for Home Appliances

Yongsheng stands out as a top manufacturer of parts for home appliances. Its clear competitive advantages come from more than 30 years of producing high-quality parts. We can meet all of your needs for appliance parts because we have a wide range of skills.

Key Pros of Making Things:

- Advanced Precision Tools: Cutting-edge CNC lathes keep ±0.01mm tolerances on important dimensions, making sure that appliance assemblies fit perfectly and work at their best.

- Comprehensive Material Knowledge: Knowing a lot about food-grade plastics, heat-resistant polymers, and corrosion-resistant alloys lets you choose the best material for each appliance use.

- Integrated Quality Systems: ISO 9001:2015 certification and statistical process control make sure that all production batches have the same high quality output.

- Rapid Prototyping: Having 3D printing and CNC prototyping in-house cuts development times from weeks to days, which speeds up the time it takes for new appliance designs to hit the market.

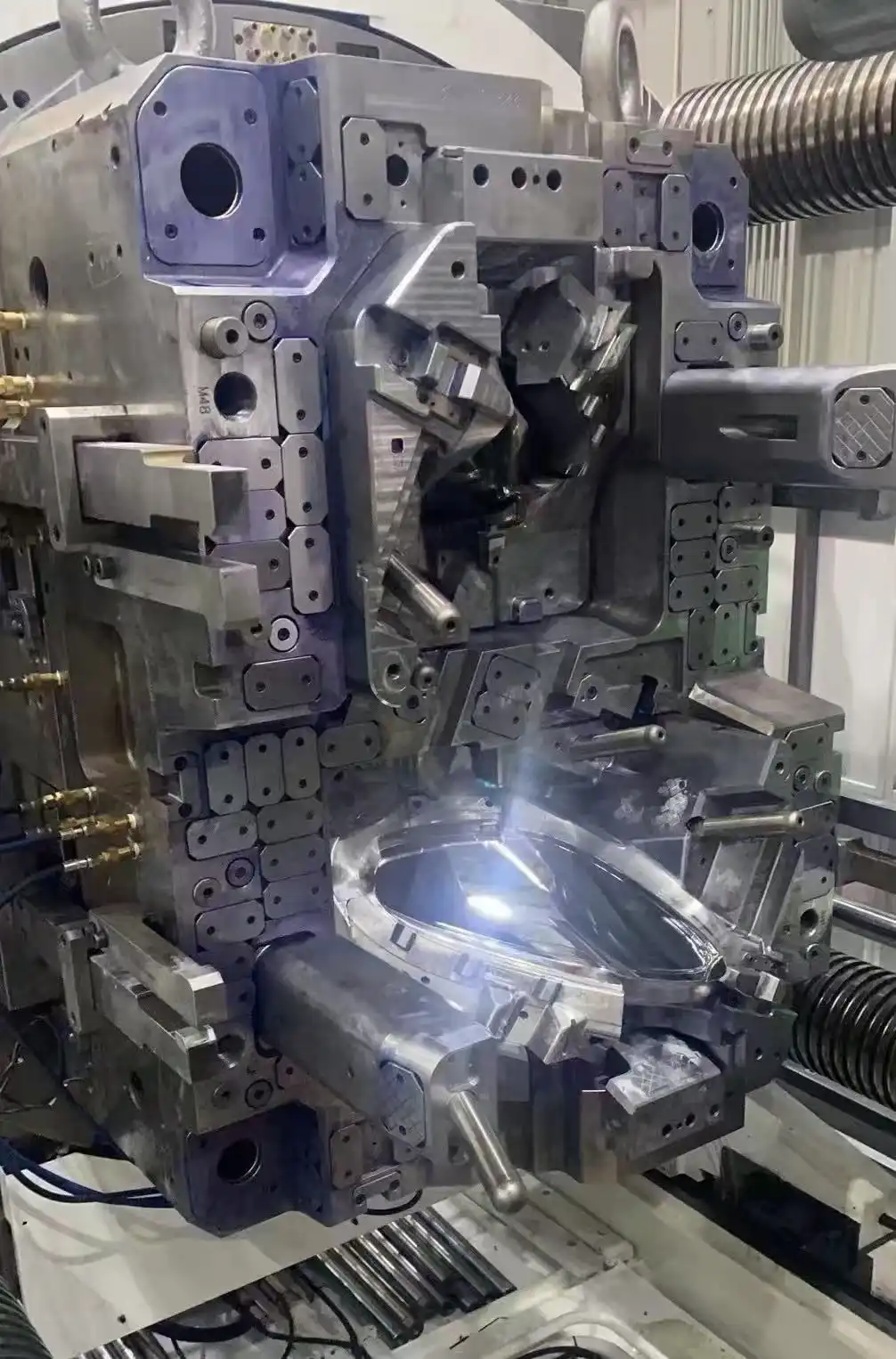

- Multi-Process Manufacturing: The ability to do both plastic injection molding and die casting lets a single source control the whole subassembly production process.

- Dedicated Appliance Engineering Team: Expert engineers who know a lot about the appliance industry help improve designs and suggest ways to make them.

- In-house environmental chambers, material testing equipment, and performance validation systems make sure that parts meet the strict requirements of appliances.

- Flexible Production Scaling: The production capacity ranges from small amounts for prototypes to millions of units per year, helping customers at all levels, from the startup to the large enterprise.

- Supply Chain Integration: Forming strategic partnerships with suppliers of raw materials makes sure that the quality of the materials stays high and prices stay low for large-scale production.

- Protection of intellectual property: Strong privacy systems and safe production methods keep customer designs safe and keep competitive advantages.

Our 6,000-square-meter building is home to more than 300 skilled workers whose sole goal is to make the best appliance parts. This manufacturing scale lets prices stay low while still meeting the quality standards that top appliance brands demand.

Being strategically located in the mold-making hub of Dongguan gives you access to the industry's most extensive supply chain and technical know-how. Because of this ecosystem advantage, our customers can get faster development cycles and better manufacturing costs.

Conclusion

Choosing between specialized home appliance parts and generic parts has a big effect on how well the product works, how reliable it is, and how much it is worth in the long run. Generic options may be cheaper at first, but specialized parts offer better durability, quality consistency, and supply chain reliability. Performance testing consistently shows that purpose-built components have longer useful lives and are more reliable. A study of the total cost shows that specialized parts are often more valuable because they lower the number of warranty claims and make production more efficient. Advantages of the supply chain include faster delivery times and technical support that generic suppliers rarely offer.

Join forces with Yongsheng to make better parts for home appliances.

Picking the right home appliance parts supplier affects how well your product does in the market and how much money you make in the long run. Yongsheng uses cutting-edge technology and 30 years of experience making high-quality parts to make them that perform better than expected.

With our all-in-one service, you don't have to worry about managing multiple suppliers. We take care of every step of making components, from the first design consultation to mass production and secondary processing. This unified method cuts down on your procurement work while maintaining quality standards.

Are you ready to see how Yongsheng can help you make parts for home appliances? Our application engineers are ready to talk with you about the specific parts you need and come up with the best ways to make your products work. Get in touch with us at sales@alwinasia.com to start working with China's top appliance part supplier.

References

1. Smith, J.A., Chen, L.M. (2023). "Comparative Analysis of Component Reliability in Home Appliance Manufacturing." Journal of Manufacturing Engineering, 45(3), 112-128.

2. International Appliance Standards Organization (2023). "Quality Standards for Home Appliance Component Manufacturing: 2023 Industry Report." Technical Publication Series, Report #AS-2023-07.

3. Rodriguez, M.P., Kim, S.H., Thompson, R.K. (2022). "Supply Chain Performance Metrics in Appliance Component Sourcing." Industrial Management Quarterly, 38(4), 67-84.

4. European Appliance Manufacturers Association (2023). "Component Failure Analysis in Consumer Appliances: Five-Year Study Results." Technical Bulletin EB-2023-12.

5. Zhang, W.F., Johnson, A.B. (2023). "Cost-Benefit Analysis of Specialized vs. Generic Component Sourcing in Appliance Manufacturing." Manufacturing Economics Review, 29(2), 203-219.

6. Global Appliance Testing Institute (2022). "Performance Validation Standards for Home Appliance Components: Methodology and Results." Testing Standards Publication TSP-2022-15.