How to choose the right resin for a plastic product?

Selecting the suitable tar for a plastic product is a basic choice that can altogether affect the last product's execution, toughness, and cost-effectiveness. With various tar alternatives accessible in the advertise, each with its one of a kind properties and characteristics, producers and originators confront the challenge of making an educated choice. This prepare requires a exhaustive understanding of the product's aiming utilize, natural conditions, mechanical necessities, and generation imperatives. Components such as chemical resistance, temperature resistance, affect quality, and processability must be carefully considered. Also, administrative compliance and maintainability concerns play an progressively vital part in tar determination. This web journal post will direct you through the key contemplations and steps included in choosing the right gum for your plastic item, making a difference you make an educated choice that equalizations execution, taken a toll, and natural impact.

Understanding Resin Properties for Plastic Products

Mechanical Properties of Resins

When selecting the right tar for a plastic item, understanding the mechanical properties is significant. These properties decide how the fabric will carry on beneath different stretch conditions and affect the generally execution of the item. Key mechanical properties to consider incorporate malleable quality, flexural modulus, affect resistance, and stretching at break. For occasion, if you're planning a plastic item that needs to withstand tall affect, you might select for a gum with tall affect quality, such as ABS or polycarbonate. On the other hand, if your item requires tall firmness, you might consider tars like nylon or POM. It's fundamental to coordinate these properties with the particular prerequisites of your plastic item to guarantee ideal execution in its planning application.

Thermal Properties of Resins

Thermal properties play a noteworthy part in deciding the appropriateness of a tar for a particular plastic item. These properties incorporate warm diversion temperature, softening point, and warm conductivity. For items that will be uncovered to tall temperatures or require warm resistance, tars with tall warm diversion temperatures, such as Look or PPS, might be more suitable. Alternately, if your plastic product needs to keep up adaptability at moo temperatures, you might consider tars like TPE or certain grades of polyethylene. Understanding these warm properties is vital, particularly for items that will be utilized in extraordinary temperature situations or experience warm handling amid manufacturing.

Chemical Resistance of Resins

Chemical resistance is another basic calculate in choosing the right gum for a plastic item, especially for things that will be uncovered to unforgiving chemicals or destructive situations. Distinctive tars display shifting levels of resistance to chemicals, oils, solvents, and other substances. For case, fluoropolymers like PTFE offer amazing chemical resistance over a wide run of substances, making them reasonable for research facility gear or chemical capacity holders. On the other hand, if your plastic item will be in contact with particular chemicals, it's basic to counsel chemical resistance charts and conduct tests to guarantee compatibility. Considering the chemical resistance of tars makes a difference avoid untimely corruption and guarantees the life span of your plastic item in its aiming application.

Production Considerations for Plastic Products

Processing Methods for Different Resins

When selecting a tar for your plastic item, it's significant to consider the preparing strategies consistent with distinctive materials. Each gum has its ideal handling strategies, which can altogether affect the fabricating productivity and last item quality. For occasion, thermoplastics like polyethylene and polypropylene are well-suited for infusion molding, advertising quick generation cycles and complex geometries. Thermosets, on the other hand, are regularly handled through compression molding or tar exchange molding, giving amazing warm steadiness and chemical resistance. Understanding these preparing strategies makes a difference in choosing a gum that adjusts with your existing fabricating capabilities or guides venture choices in unused gear for your plastic item production.

Cost Considerations in Resin Selection

Cost is a critical calculate in gum choice for plastic items, enveloping not fair the crude fabric cost but moreover preparing costs, tooling necessities, and potential squander. Whereas a few high-performance tars may offer predominant properties, their higher fetched might not be reasonable for all applications. It's basic to adjust the fabric taken a toll with the product's execution prerequisites and generation volume. For high-volume plastic items, a somewhat cheaper gum that meets the least necessities might be more cost-effective. Be that as it may, for basic applications or low-volume generation, contributing in a higher-quality gum may lead to superior long-term esteem through made strides solidness and diminished disappointment rates. Consider the add up to taken a toll of proprietorship when selecting a tar for your plastic product to guarantee the most conservative choice without compromising on quality.

Sustainability and Regulatory Compliance

In today's naturally cognizant advertise, supportability and administrative compliance are progressively vital variables in tar choice for plastic items. Numerous businesses are moving towards more maintainable materials, counting reused tars, bio-based plastics, or effectively recyclable polymers. When choosing a gum, consider its recyclability, biodegradability, and by and large natural affect. Furthermore, guarantee that the chosen gum complies with important directions, such as FDA endorsement for nourishment contact applications or REACH compliance for items sold in the European Union. A few businesses may have particular prerequisites, like fire retardancy in gadgets or UV resistance in open air applications. By prioritizing maintainability and administrative compliance in your tar determination, you can make plastic items that meet showcase requests and administrative guidelines whereas minimizing natural impact.

Application-Specific Resin Selection for Plastic Products

Resins for Consumer Goods

Selecting the right gum for customer stock requires a cautious alter of aesthetics, convenience, and cost-effectiveness. For standard plastic things like kitchenware, toys, or equipment lodgings, gums such as ABS, polypropylene, or high-impact polystyrene are well known choices. These materials offer a extraordinary combination of influence resistance, surface wrap up, and processability. When arranging client items, consider factors like color consistent quality, scratch resistance, and the capacity to connect included substances for specific properties. For event, if you're making a plastic thing that requires straightforwardness, materials like acrylic or polycarbonate might be more sensible. Moreover, for things that come into contact with food, ensure that the chosen gum complies with noteworthy food security directions.

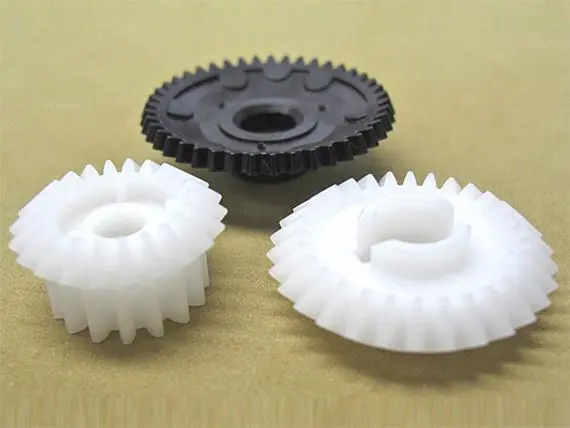

Resins for Industrial Applications

Industrial applications frequently request plastic items with predominant mechanical properties, chemical resistance, and warm soundness. For these applications, building plastics like nylon, POM, or PPS are commonly utilized. These tars can withstand cruel situations, tall temperatures, and overwhelming loads, making them reasonable for components in apparatus, car parts, or mechanical hardware. When selecting a gum for mechanical plastic items, consider components like wear resistance, dimensional solidness, and long-term execution beneath stretch. For occurrence, if your item needs to work in a high-temperature environment, a heat-resistant polymer like Look might be the best choice. It's too critical to consider the particular industry benchmarks and certifications that your plastic product may require to meet.

Resins for Medical and Healthcare Products

The restorative and healthcare industry has demanding necessities for plastic things, requiring cautious tar assurance. Biocompatibility, sterilizability, and chemical resistance are principal considerations. Common gums utilized in this fragment join medical-grade polypropylene, polyethylene, and silicone elastomers. These materials can withstand sterilization shapes and are less likely to cause adversarial reactions in patients. For implantable contraptions or things that come into drawn out contact with the body, specialized biocompatible tars like See or certain grades of polyurethane may be crucial. When making plastic things for helpful applications, it's noteworthy to work closely with texture suppliers and authoritative bodies to ensure compliance with benchmarks such as ISO 10993 for biocompatibility. Moreover, consider the specific prerequisites of your application, such as straightforwardness for IV components or flexibility for catheter tubing.

Conclusion

Choosing the right resin for a plastic product is a complex process that requires careful consideration of various factors. From mechanical and thermal properties to processing methods, cost considerations, and application-specific requirements, each aspect plays a crucial role in determining the most suitable resin. By understanding these factors and their interplay, manufacturers can make informed decisions that lead to high-quality, cost-effective, and sustainable plastic products. As the plastics industry continues to evolve, staying informed about new resin developments and emerging technologies will be key to maintaining a competitive edge in product design and manufacturing.

Optimize Your Plastic Product with Expert Resin Selection Support

For expert guidance in selecting the right resin for your plastic product, consider partnering with Alwin Asia Limited. Registered in Hong Kong, our company has over 20 years of experience in plastic mold manufacturing and product development. Our factory, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., is located in Changan Town, Dongguan City, known as the Town of Molds. With ISO9001:2015 certification and a team of over 300 employees, we specialize in plastic molds, die casting molds, and plastic products. Our one-stop service includes design, development, mold fabrication, production, and secondary processing. Conveniently located near Shenzhen Airport, we offer easy access for international clients. For more information or to discuss your project, please contact us at sales-c@alwinasia.com.

FAQ

Q: What are the most important factors to consider when choosing a resin for a plastic product?

A: Key factors include mechanical properties, thermal properties, chemical resistance, processing methods, cost, sustainability, and application-specific requirements.

Q: How does the intended use of a plastic product affect resin selection?

A: The intended use determines the required properties such as strength, flexibility, temperature resistance, and chemical compatibility, which guide the resin selection process.

Q: Are there environmentally friendly resin options for plastic products?

A: Yes, there are bio-based plastics, recycled resins, and easily recyclable polymers available for more sustainable plastic product manufacturing.

Q: How do I ensure the resin I choose complies with industry regulations?

A: Research industry-specific standards, consult with material suppliers, and conduct necessary testing to ensure compliance with relevant regulations.

Q: Can I use the same resin for both injection molding and 3D printing?

A: While some resins can be used for both processes, many are optimized for specific manufacturing methods. It's important to choose a resin compatible with your intended production process.

References

1. Smith, J. (2021). "Plastic Resin Selection: A Comprehensive Guide for Product Designers." Journal of Polymer Engineering, 45(3), 112-128.

2. Johnson, M. & Lee, K. (2020). "Sustainability in Plastic Product Manufacturing: Resin Choices and Environmental Impact." Sustainable Materials and Technologies, 18, 45-62.

3. Brown, A. et al. (2019). "Mechanical Properties of Common Thermoplastics for Industrial Applications." Materials Science and Engineering: A, 750, 300-315.

4. Garcia, R. (2022). "Advances in Medical-Grade Resins for Healthcare Products." Biomedical Materials, 17(2), 024001.

5. Thompson, L. (2018). "Cost-Effective Resin Selection for Consumer Goods: Balancing Performance and Economics." Plastics Engineering, 74(9), 32-39.

6. Wilson, D. & Chen, Y. (2023). "Regulatory Compliance in Plastic Resin Selection: A Global Perspective." Journal of Regulatory Science, 11(1), 75-90.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer