Inserts Molding Tools: Key Features for Russian OEMs

Russian Original Equipment Manufacturers (OEMs) are always looking for new ways to improve their production processes in the ever-changing world of manufacturing. Using inserts molding tools is one method that has become quite popular. These new tools have changed the way OEMs make plastic parts by giving them unmatched accuracy, speed, and cost-effectiveness. Inserts molding tools make it easy to add metal or other materials to plastic parts during the injection molding process. This makes the products stronger and longer-lasting. This article goes into detail about the most important aspects of inserts molding tools that make them essential for Russian OEMs. It looks at their benefits, uses, and the huge difference they make in production processes. OEMs may make smart choices about how to improve their production processes and stay competitive in the global market by knowing these important things.

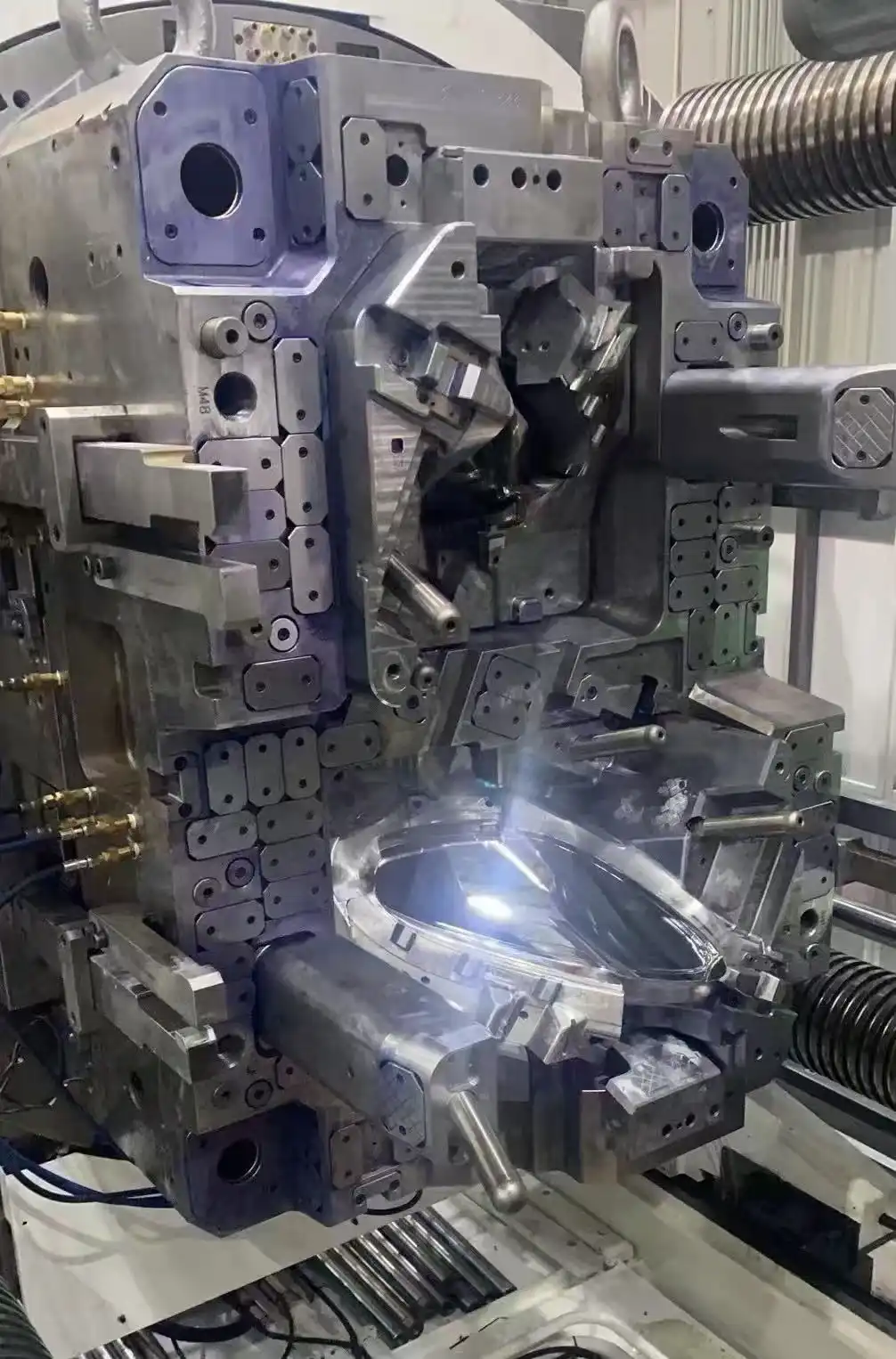

Precision Engineering in Inserts Molding Tools

Advanced Design Techniques

Inserts molding tools are the most precise instruments used in the manufacturing business. These tools are carefully made using the latest CAD/CAM software, which lets for very small details and very tight tolerances. Russian OEMs can benefit from the advanced design methods used to make these tools, which ensure that each insert is in the right place and held firmly in the mold cavity. To make high-quality parts with repeatable dimensional accuracy, this degree of precision is very important. Engineers may utilize simulation software to improve the design process even further. This lets them improve the performance of tools and find problems that might happen before production starts. Inserts molding tools may greatly cut down on the requirement for post-molding activities by using these sophisticated design approaches. This makes the production process more efficient and faster.

Material Selection and Compatibility

One of the key features of inserts molding tools is their ability to accommodate a wide range of materials. Russian OEMs can take advantage of this versatility to create innovative products that combine the strengths of different materials. The tools are designed to ensure compatibility between the insert material and the molded plastic, preventing issues such as thermal expansion mismatches or chemical incompatibility. This feature allows manufacturers to produce complex components with enhanced mechanical properties, such as metal-reinforced plastic parts or electronics enclosures with integrated heat sinks. The careful selection of materials for both the inserts and the molding tools themselves contributes to the longevity and reliability of the manufacturing process, making inserts molding an attractive option for Russian OEMs looking to improve their product offerings.

Thermal Management Capabilities

Inserts molding requires good temperature management, and contemporary equipment come with enhanced capabilities to help with this problem. Russian OEMs can use tools with advanced cooling channels that are put in the right places to make sure that heat is spread evenly and the molded product cools quickly. This capability is very significant when working with materials that are sensitive to temperature or when using inserts that have different thermal characteristics than the plastic around them. Inserts molding tools can assist lower cycle times, eliminate warpage, and enhance the overall quality of parts by improving heat management. Some modern machines also use conformal cooling techniques, which follow the shape of the part, to make cooling even more efficient and to make it possible to create more complicated designs with great accuracy.

Automation and Efficiency in Inserts Molding

Robotic Insert Placement Systems

In today's industry, automation is very important, and inserts molding tools are no different. Russian OEMs can use automatic insert placement systems to make their production processes more reliable and efficient. These automatic systems use advanced vision technology and precise robotic arms to place inserts precisely inside the mold cavity. This makes sure that the placement is always the same and lowers the chance of human mistakes. Adding robots not only speeds up production, but it also makes it possible to run the business 24 hours a day, seven days a week, which increases output and lowers worker costs. These systems can also be set up to work with different shapes and sizes of inserts, which gives them the adaptability they need to work with different product lines. Russian OEMs can improve quality control, boost output, and increase their total working efficiency in their insert molding processes by using robotic insert placement.

Quick-Change Mold Systems

Flexibility and rapid changeover capabilities are essential for Russian OEMs looking to stay competitive in today's fast-paced manufacturing environment. Insert molding tools equipped with quick-change mold systems offer a significant advantage in this regard. These systems allow for swift and efficient mold changes, reducing downtime between production runs and enabling manufacturers to respond quickly to market demands. The quick-change feature typically involves modular mold designs, standardized mounting systems, and automated clamping mechanisms. This allows operators to switch between different product molds in a matter of minutes rather than hours, greatly enhancing production flexibility. For Russian OEMs dealing with diverse product lines or frequent design iterations, the ability to rapidly change molds can lead to substantial time and cost savings, improving overall production efficiency and responsiveness to customer needs.

In-Mold Monitoring and Quality Control

In manufacturing, quality control is very important. Insert molding tools include extensive in-mold monitoring features that help make sure that the product is always of excellent quality. Tools with sensors that keep an eye on important factors like pressure, temperature, and flow rates in real time during the molding process might help Russian OEMs. You may utilize this information to find and fix problems as they happen, which will lower the number of faults and scrap. Some sophisticated systems also use AI and machine learning algorithms to look at production data and automatically change process settings to make them work better. This level of monitoring and control makes it possible to make complicated pieces with very tight tolerances and ensures that each insert is correctly encased in the molded portion. By using these new quality control tools, Russian OEMs can keep their products at a high level of quality while cutting down on waste and making the whole manufacturing process more efficient.

Sustainability and Cost-Effectiveness in Inserts Molding

Energy-Efficient Designs

As sustainability becomes more essential in production, injection molding tools are changing to meet these needs. Russian OEMs can use designs that use less energy without losing performance. These tools frequently use lightweight materials and heating technologies that use less energy during the molding process. Also, improved insulation methods and accurate temperature control systems assist in keeping the best working conditions with the least amount of energy used. Some injection molding machines also have regenerative systems that absorb and utilize heat that is created throughout the molding cycle. This makes them even more energy-efficient. By using these energy-efficient designs, Russian OEMs may not only decrease their impact on the environment, but they can also save a lot of money on production, which will help them reach their sustainability targets and make more money.

Waste Reduction and Material Optimization

Inserts molding tools offer significant advantages in terms of waste reduction and material optimization, making them an attractive option for Russian OEMs focused on lean manufacturing principles. These tools are designed to minimize material waste through precise control of the injection process, reducing the occurrence of flash and other defects that lead to scrapped parts. Advanced runner systems and hot-runner technology further contribute to material savings by eliminating or reducing the need for sprues and runners. Additionally, the ability to integrate metal inserts into plastic components often allows for the use of less expensive materials without compromising product strength or functionality. This optimization of material usage not only reduces raw material costs but also contributes to sustainability efforts by minimizing the overall environmental impact of the manufacturing process. Russian OEMs can leverage these features to create more eco-friendly products while simultaneously improving their bottom line.

Long-Term Cost Benefits

While the initial investment in high-quality inserts molding tools may be substantial, Russian OEMs stand to gain significant long-term cost benefits. These tools are built to withstand the rigors of high-volume production, offering exceptional durability and longevity. The use of wear-resistant materials and advanced surface treatments extends the lifespan of the tools, reducing the frequency of replacements and associated downtime. Furthermore, the precision and consistency offered by these tools lead to fewer rejects and less post-molding processing, resulting in substantial savings over time. The ability to produce complex parts in a single molding operation also eliminates the need for secondary assembly steps, streamlining production and reducing labor costs. When considering the total cost of ownership, including factors such as maintenance, energy consumption, and production efficiency, inserts molding tools prove to be a cost-effective solution for Russian OEMs looking to optimize their manufacturing processes and maintain a competitive edge in the global market.

Conclusion

Inserts molding tools have emerged as a game-changing technology for Russian OEMs, offering a perfect blend of precision, efficiency, and cost-effectiveness. By leveraging advanced design techniques, automated systems, and sustainable practices, these tools enable manufacturers to produce high-quality, complex components with unprecedented speed and accuracy. The integration of metal inserts into plastic parts opens up new possibilities for product design and functionality, while the focus on energy efficiency and waste reduction aligns with growing environmental concerns. As Russian OEMs continue to seek ways to innovate and stay competitive in the global market, inserts molding tools stand out as a crucial investment that can drive growth, improve product quality, and enhance overall manufacturing capabilities.

For those interested in exploring the potential of inserts molding tools, Alwin Asia Limited, registered in Hong Kong, offers comprehensive solutions through its subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience in plastic mold, die casting mold, and plastic products manufacturing, Yongsheng is well-equipped to provide OEM services, including design, development, mold fabrication, production, and secondary processing. Located in Chang'an Town, Dongguan City—known as the Town of Molds—the company boasts a 6000 square meter facility and has obtained ISO9001:2015 certification. Their commitment to quality, cost-effectiveness, and timely delivery makes them an ideal partner for Russian OEMs looking to implement inserts molding technology. For more information or to discuss your specific needs, please contact them at sales-c@alwinasia.com.

FAQ

What are the main advantages of using insert molding tools for Russian OEMs?

Insert molding tools offer precision engineering, improved efficiency through automation, and cost-effectiveness through waste reduction and energy-efficient designs.

How do insert molding tools contribute to sustainability in manufacturing?

These tools reduce material waste, optimize energy consumption, and allow for the production of more durable products that combine the strengths of different materials.

What types of products can be manufactured using insert molding tools?

Insert molding tools can produce a wide range of products, including metal-reinforced plastic parts, electronics enclosures with integrated heat sinks, and complex components for various industries.

How do robotic insert placement systems improve the manufacturing process?

Robotic systems enhance accuracy, increase production speed, reduce human error, and allow for 24/7 operation, significantly improving overall efficiency.

What are the long-term cost benefits of investing in high-quality insert molding tools?

High-quality tools offer durability, reduced downtime, fewer rejects, and the ability to produce complex parts in a single operation, leading to significant cost savings over time.

References

1. Rosato, D. V., & Rosato, M. G. (2012). Injection Molding Handbook (3rd ed.). Springer Science & Business Media.

2. Goodship, V. (2017). Practical Guide to Injection Moulding (2nd ed.). Smithers Rapra.

3. Johannaber, F. (2016). Injection Molding Machines: A User's Guide (5th ed.). Carl Hanser Verlag GmbH & Co. KG.

4. Osswald, T. A., & Hernández-Ortiz, J. P. (2018). Polymer Processing: Modeling and Simulation. Carl Hanser Verlag GmbH & Co. KG.

5. Kazmer, D. O. (2016). Injection Mold Design Engineering (2nd ed.). Carl Hanser Verlag GmbH & Co. KG.

6. Mennig, G., & Stoeckhert, K. (2013). Mold-Making Handbook (3rd ed.). Carl Hanser Verlag GmbH & Co. KG.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer