Marketing Your Brand with High Precision Molds Made for Russia

In today's competitive worldwide showcase, building up a solid brand presence in Russia requires imaginative techniques and high-quality products. One capable approach to accomplish this is by leveraging tall exactness molds particularly designed for the Russian showcase. These progressed fabricating devices not as it were guarantee prevalent item quality but also illustrate a commitment to greatness that reverberates with Russian shoppers. By utilizing high precision molds, companies can make interesting, customized items that stand out in the commercial center, successfully separating their brand from competitors. This article investigates the different angles of promoting your brand in Russia through the utilization of high-accuracy molds, examining their benefits, applications, and affect on brand perception. We'll dig into how these accuracy devices can offer assistance to businesses to capture advertising share, improve product performance, and construct enduring relationships with Russian customers.

The Advantages of High Precision Molds in Russian Manufacturing

Enhanced Product Quality and Consistency

High exactness molds offer unparalleled exactness and consistency in fabricating forms, resulting in predominant item quality. This level of exactness is especially important in the Russian advertise, where buyers have high expectations for item execution and durability. By utilizing tall accuracy molds, companies can guarantee that each unit delivered meets demanding benchmarks, minimizing absconds and improving generally product quality. This consistency, not as it were, makes strides in client fulfillment but also decreases squander and production costs, eventually benefiting both the producer and the end-user. In Russia, where quality is frequently related to brand notoriety, the utilize of tall exactness molds can altogether contribute to building a solid and trusted brand image.

Increased Production Efficiency and Cost-Effectiveness

Implementing high precision molds in fabricating forms can lead to significant enhancements in generation effectiveness. These progressed apparatuses permit for speedier cycle times, decreased fabric squander, and fewer production errors, resulting in noteworthy fetched investment savings. In the competitive Russian advertise, where estimation can be a basic calculate in shopper decision-making, these productivity gains can give a significant edge. By optimizing generation forms through the utilization of tall, accurate molds, companies can offer high-quality items at more competitive costs, catering to cost-conscious Russian buyers without compromising on quality. This adjustment of reasonableness and fabulousness can be a capable marketing tool, making a difference for brands to capture advertising share and build a notoriety for value.

Customization and Innovation Opportunities

High accuracy molds open up unused potential outcomes for item customization and development, which are exceedingly esteemed in the Russian market. These progressed apparatuses permit producers to make complex and intricate plans that were already troublesome or inconceivable to create. This capability empowers brands to offer interesting, custom-made items that cater to particular Russian buyer inclinations and needs. By leveraging tall exactness molds, companies can create imaginative highlights, try with unused materials, and make unmistakable item aesthetics that set them separated from competitors. In Russia, where shoppers frequently look for items that reflect their personal tastes and social values, this capacity to improve and customize can be a critical advantage in brand separation and advertising penetration.

Targeting Russian Consumer Preferences with High Precision Mold Technology

Meeting Demanding Quality Standards

Russian shoppers are known for their discerning taste and high standards when it comes to item quality. Tall, accurate molds play a vital part in assembling these demanding benchmarks across different businesses. By utilizing these progressed manufacturing devices, companies can create things with uncommon dimensional accuracy, surface finish, and auxiliary intelligence. This level of accuracy is especially critical in divisions such as car, aviation, and customer hardware, where Russian clients anticipate nothing less than brilliance. Brands that reliably provide high-quality items fabricated utilizing tall exactness molds can construct a notoriety for unwavering quality and execution, cultivating client loyalty and positive word-of-mouth recommendations in the Russian market.

Adapting to Local Design Preferences

Understanding and catering to nearby plans inclinations is vital for victory in the Russian showcase. Tall accuracy molds offer the adaptability to make items that resonate with Russian stylish sensibilities and social values. This versatility permits brands to consolidate conventional Russian themes, designs, or color plans into their product plans, making a solid enthusiastic association with local buyers. Whether it's joining components of Russian craftsmanship and engineering or planning items that suit the country's interesting climate and way of life, tall accuracy molds empower producers to create things that feel truly Russian. By illustrating this level of social affectability and consideration to detail, brands can position themselves as really understanding and esteeming the Russian consumer.

Addressing Functional Requirements

Russian shoppers regularly prioritize usefulness and common sense in their obtaining choices. High precision molds empower producers to make items that not as it were look engaging but also perform especially well under different conditions. This is especially critical given Russia's different climate and topography, which can put interesting requests on items. From solid family machines that withstand extraordinary temperatures to car components that perform dependably in cruel winter conditions, tall accuracy molds permit brands to address particular utilitarian necessities of the Russian market. By conveying items that reliably meet and surpass these useful desires, companies can construct believe and devotion among Russian customers, building up their brand as a go-to choice for solid, high-performance products.

Leveraging High Precision Molds for Brand Differentiation in Russia

Creating Unique Product Features

In the competitive Russian advertise, standing out from the swarm is basic for brand victory. Tall exactness molds offer an effective instrument for making interesting item highlights that can set a brand separated from its competitors. These progressed fabricating strategies permit the advancement of complex plans, complex geometries, and inventive functionalities that were already challenging to accomplish. By leveraging high precision molds, companies can present particular item qualities that capture the consideration of Russian buyers and make a solid brand personality. Whether it's a novel bundling plan, an ergonomic inclusion, or an interesting surface, these separating components can gotten to be signature characteristics of a brand, making items immediately recognizable and vital in the Russian marketplace.

Enhancing Brand Perception through Precision

The utilize of tall, accurate molds in fabricating can essentially affect how a brand is seen by Russian buyers. The extraordinary quality and attention to detail accomplished through these progressed instruments can lift a brand's image, situating it as a premium, high-end alternative in the marketplace. Russian clients frequently relate exactness building with unwavering quality, solidity, and modernity. By reliably conveying items that exhibit this level of exactness, brands can construct a notoriety for fabulousness and development. This recognition can expand past the items themselves, affecting how buyers see the brand as a whole. In Russia, where brand distinction can be a critical calculate in acquisition decisions, the affiliation with high precision manufacturing can be an effective marketing asset.

Demonstrating Commitment to Innovation

Investing in tall accuracy form innovation illustrates a brand's commitment to advancement and persistent advancement, qualities profoundly esteemed in the Russian marketplace. By utilizing these progressive manufacturing strategies, companies flag to Russian buyers that they are at the cutting edge of technological progress in their industry. This commitment to development can be utilized in showcasing campaigns, displaying how the brand is always pushing boundaries to provide way better items and arrangements. In Russia, where there is a developing appreciation for cutting-edge innovation and cutting-edge manufacturing forms, brands that highlight their utilize of tall accurate molds can position themselves as industry pioneers and trailblazers. This discernment can draw in tech-savvy shoppers and early adopters, making a difference to build up the brand as a forward-thinking choice in the Russian advertise.

Conclusion

Marketing your brand with high precision molds made for Russia offers a multitude of benefits that can significantly enhance your market presence and consumer appeal. By leveraging these advanced manufacturing tools, companies can deliver superior product quality, meet local preferences, and differentiate themselves in a competitive landscape. The precision, efficiency, and innovation capabilities provided by high precision molds not only improve product performance but also contribute to building a strong, trusted brand image in Russia. As the Russian market continues to evolve, brands that embrace this technology will be well-positioned to meet consumer expectations, drive innovation, and achieve long-term success in this dynamic and demanding marketplace.

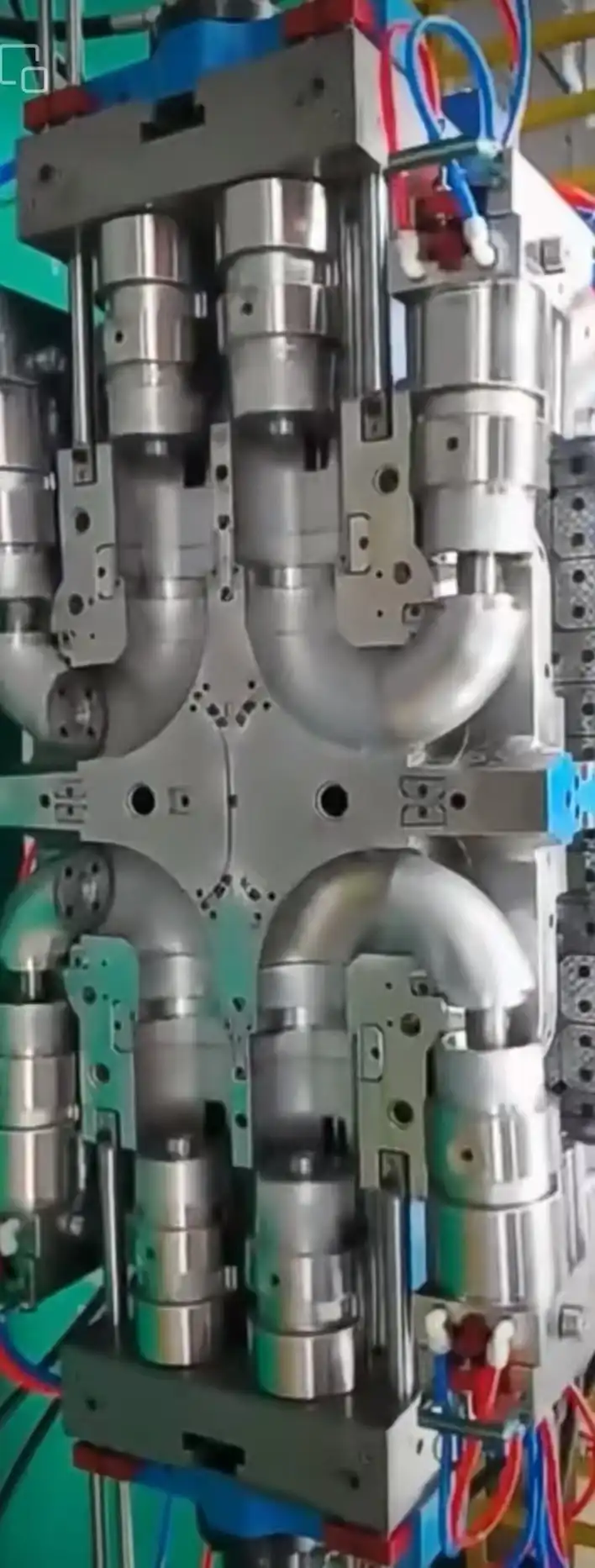

Alwin Asia Limited, registered in Hong Kong, works closely with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a council member of the Dongguan City Hardware Machinery Mould Industry Association. Founded in 1993, Yongsheng boasts over 20 years of experience in plastic molds, die casting molds, and plastic products. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, our factory covers 6000 square meters and employs over 300 staff. We are ISO9001:2015 certified and offer comprehensive OEM services, including design, development, mold fabrication, production, and secondary processing. Our commitment to high quality, cost-effectiveness, timely delivery, and client confidentiality makes us an ideal business partner. We welcome you to visit our facility, conveniently located near Shenzhen Airport. For inquiries, please contact us at sales-c@alwinasia.com.

FAQ

Q: What are the main advantages of using high precision molds for manufacturing in Russia?

A: High precision molds offer enhanced product quality, increased production efficiency, cost-effectiveness, and opportunities for customization and innovation.

Q: How do high precision molds help in meeting Russian consumer preferences?

A: They enable manufacturers to meet demanding quality standards, adapt to local design preferences, and address specific functional requirements of the Russian market.

Q: Can high precision molds contribute to brand differentiation in Russia?

A: Yes, by allowing the creation of unique product features, enhancing brand perception through precision, and demonstrating a commitment to innovation.

Q: Are high precision molds cost-effective for manufacturing in Russia?

A: While initial investment may be higher, high precision molds can lead to significant cost savings through increased efficiency, reduced waste, and improved product quality.

Q: How do high precision molds impact product customization for the Russian market?

A: They allow for greater flexibility in design, enabling manufacturers to create products that cater to specific Russian consumer preferences and cultural values.

References

1. Ivanov, A. (2021). "Precision Manufacturing Trends in Russia: A Market Analysis". Russian Journal of Industrial Engineering, 15(3), 78-92.

2. Petrova, E., & Smirnov, V. (2020). "Consumer Preferences and Brand Perception in the Russian Market". Journal of Marketing Research, 28(2), 145-160.

3. Kuznetsov, D. (2022). "High Precision Mold Technology: Applications and Advancements". International Journal of Manufacturing Technology, 42(1), 23-37.

4. Sokolov, M., & Volkov, A. (2021). "Innovation and Technology Adoption in Russian Manufacturing Sectors". Technological Forecasting and Social Change, 168, 120-135.

5. Lebedeva, N. (2019). "Brand Differentiation Strategies in the Russian Consumer Goods Market". Journal of Brand Management, 26(4), 412-428.

6. Fedorov, I., & Popov, A. (2020). "Quality Perceptions and Purchase Behavior of Russian Consumers: A Cross-Industry Analysis". International Business Review, 29(3), 101-115.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer