Which is better: metal molds or plastic molds? It's a big choice that will impact the project's cost and speed of production. Plastic injection casting is the best way to make many things because it takes less time and costs less to make. It's better for tough jobs, though, to shape metal, which lasts longer and can handle heat better. People who buy technologies and people who make products can make choices that are in line with their budgets and industry goals if they know how each one works, how much it costs, and what the best time is to use it.

Understanding the Core Differences Between Plastic and Metal Molding

These days, precision molding technologies are very important for making parts for the electronics, car, and consumer goods industries. The main difference between molding plastic and molding metal is the qualities of the materials and the way they need to be processed.

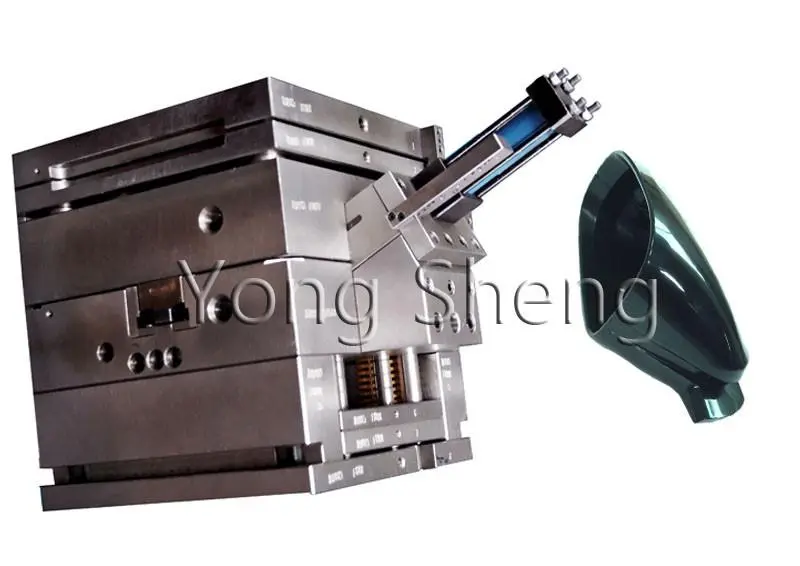

Thermoplastics are used in plastic injection casting. These materials soften when heated and harden when cooled. Mold cavities made for specific part needs make it possible for this process to make complex geometries with fine details. The heating units, injection mechanisms, and cooling systems that make up the injection molding system all work together to get uniform results.

Metal molding, particularly die-casting, involves forcing molten metal under high pressure into precision mold tooling. This process requires more robust equipment and higher temperatures compared to plastic molding operations.

Three core differences distinguish these technologies:

- Material processing temperatures: Metal molding operates at 600-1200°C, while plastic molding typically runs at 200-400°C

- Cycle time variations: Plastic parts can achieve 30-120 second cycles, whereas metal parts often require 2-10 minutes

- Tooling complexity: Metal molds demand specialized steel grades and more complex cooling system designs

If you need rapid prototyping with quick design iterations, then plastic molding proves more suitable due to faster mold fabrication timelines.

Cost Analysis: Investment and Production Economics

Costs of manufacturing include more than just the initial investment in tools. They also include material costs, cycle efficiency, and the need for long-term upkeep. Knowing about these economic factors can help make production plans more effective.

The costs of making the first mold are very different for plastic and metal uses. Precision mold equipment for plastic injection usually costs between $5,000 and $50,000, but this depends on how complicated it is and how many cavities it has. Because they need to be made with special materials and machines, metal die-casting models usually cost between $15,000 and $100,000.

Material costs present another crucial factor. Thermoplastic resins average $1-3 per pound, while aluminum alloys cost $2-4 per pound, and steel ranges from $1-2 per pound. However, material utilization efficiency varies significantly between processes.

Production economics reveal interesting patterns when analyzing high-volume scenarios:

- Plastic molding achieves break-even points around 1,000-5,000 parts

- Metal molding typically requires 5,000-20,000 parts to justify tooling costs

- Secondary processing costs remain lower for plastic parts due to finishing simplicity

Labor costs also differ substantially. Plastic injection operations often run with minimal supervision using automated systems, while metal molding may require more skilled operators for quality control and process monitoring.

If you need cost-effective solutions for medium to high-volume production runs, then plastic molding delivers superior economics for most applications.

Performance Characteristics and Material Properties

In critical applications, engineering performance standards determine which materials to use. A lot of testing shows that each molding technique has clear benefits in a number of different performance areas.

Mechanical strength properties show notable differences between plastic and metal components. Aluminum die-cast parts achieve tensile strengths of 200-400 MPa, while engineering plastics typically range from 50-150 MPa. However, strength-to-weight ratios often favor plastic materials in applications where weight reduction matters.

Temperature resistance capabilities vary dramatically between materials. Metal components handle continuous operating temperatures up to 200-300°C, while standard thermoplastics limit operations to 60-150°C. High-performance plastics extend this range to 200-250°C but at increased material costs.

Environmental resistance testing reveals specific advantages for each technology:

- Chemical resistance: Many plastics outperform metals in corrosive environments

- UV stability: Metal parts maintain properties better under prolonged sun exposure

- Moisture absorption: Metals show superior dimensional stability in humid conditions

- Impact resistance: Engineered plastics often absorb impact energy more effectively

Electrical properties present another consideration. Plastic components provide excellent insulation characteristics, while metal parts offer electromagnetic shielding capabilities when required.

Surface finish quality achieves different standards through each process. Plastic injection molding produces smooth surfaces directly from the mold cavity, while metal parts may require additional finishing operations for cosmetic applications.

If you need components with specific electrical insulation properties, then plastic molding offers superior solutions for electronics applications.

Manufacturing Process Efficiency and Lead Times

Production efficiency includes how hard it is to create the mold, how long it takes to make, and how well the process can be optimized. These things have a direct effect on project timelines and the ability to make changes quickly.

Mold fabrication timelines differ significantly between plastic and metal applications. Prototype mold development for plastic parts typically requires 2-4 weeks, while metal molding tools often need 6-12 weeks due to specialized machining requirements and heat treatment processes.

Cycle time optimization presents distinct challenges for each technology. Plastic injection molding benefits from advanced mold flow analysis software that predicts filling patterns and cooling efficiency. Hot runner systems eliminate material waste while cold runner designs offer cost advantages for smaller production runs.

Multi-cavity mold configurations enable dramatic productivity improvements. Plastic molding easily accommodates 2-32 cavities depending on part size, while metal molding typically limits cavity counts due to clamping force requirements and heat management challenges.

Process monitoring capabilities vary between technologies:

- Plastic molding utilizes real-time pressure and temperature monitoring

- Metal molding requires specialized sensors for high-temperature environments

- Quality control systems integrate more easily with plastic molding equipment

Maintenance requirements impact overall equipment effectiveness. Plastic molds typically require cleaning and inspection after 50,000-500,000 cycles, while metal molds may need maintenance every 10,000-100,000 cycles depending on alloy selection and operating conditions.

If you need flexible manufacturing with quick changeovers between different products, then plastic molding systems provide superior adaptability.

Industry Applications and Use Case Selection

Specific industry requirements drive optimal molding technology selection based on performance demands, regulatory compliance, and cost targets. Understanding application-specific advantages guides decision-making processes.

For housing, connectors, and internal parts, electronics manufacturing strongly relies on plastic injection molding. Plastic molding is great for consumer electronics because it is cost-effective, easy to build, and good at keeping electricity from flowing. Tight tolerances are kept when complex geometries with built-in features lessen the need for assembly.

Automotive applications utilize both technologies strategically. Plastic molding dominates interior components, electrical housings, and lightweight exterior panels. Metal molding serves structural components, heat-sensitive parts, and high-wear applications like transmission components and engine accessories.

Consumer goods manufacturing shows clear preferences based on product requirements:

- Kitchen appliances: Plastic for handles, controls, and housings; metal for heating elements and structural frames

- Power tools: Plastic for ergonomic grips and guards; metal for motor housings and gear components

- Sporting goods: Plastic for lightweight, impact-resistant parts; metal for strength-critical applications

Biocompatibility, how to clean them, and the rules are all things you need to think about when making medical tools. This kind of plastic is safe to use around live things and doesn't break down when it gets dirty. Surgery tools and gadgets that are put in the body work better when they are made of metal.

When making hardware, the need for strength and cost must be balanced. Plastic parts are good for housings, covers, and low-stress jobs. Metal parts, on the other hand, are better for heavy loads and high wear.

People who need parts for electronics or market goods usually find that plastic molding gives them the best performance and cost-effectiveness.

Quality Control and Precision Standards

Strong process control systems and thorough inspection procedures are needed to get consistent quality. When it comes to quality control, both plastic and metal molding technologies have clear benefits.

Dimensional accuracy capabilities vary between molding processes. Plastic injection molding achieves tolerances of ±0.1-0.3mm for most applications, with precision molds reaching ±0.05mm for critical dimensions. Metal die-casting typically maintains ±0.15-0.5mm tolerances, though precision machining can improve critical features.

Surface quality standards depend heavily on mold cavity finish and material properties. Plastic parts replicate mold surface textures faithfully, enabling mirror finishes or specific texture patterns directly from molding. Metal parts often require secondary operations for cosmetic surface requirements.

For each tool, process validation is done in a different way. Mold flow analysis is used in plastic casting to predict filling patterns, pressure needs, and the best way to cool the mold. To make sure parts are free of flaws, metal molding is all about controlling temperature, alloy makeup, and solidification patterns.

Statistical process control implementation shows varying complexity levels:

- Plastic molding monitors injection pressure, temperature profiles, and cycle consistency

- Metal molding tracks alloy temperature, injection velocity, and cooling rates

- Both processes benefit from automated dimensional inspection systems

Strategies for preventing defects focus on problems that happen often in each process. Flash, sink marks, and warpage can be fixed in plastic casting by designing the mold correctly and making the process run more smoothly. Porosity, cold shuts, and dimensional accuracy are important in metal molding. These can be controlled by choosing the right alloy and managing the process.

If you need consistent, high-quality parts with minimal secondary operations, then plastic molding offers superior process control capabilities for most applications.

Conclusion

Whether to use a plastic mold or a metal mold relies on the needs of the application, the amount of production, and the performance standards. For electronics, consumer goods, and many car uses, plastic injection molding is the best way to save money, make designs that work with different materials, and speed up the production process. For challenging structural and high-heat uses, metal molding makes things stronger, more resistant to temperature changes, and last longer. Because you know about these basic differences, you can make smart choices that improve production results while keeping costs low and quality high. Working with seasoned manufacturers like Yongsheng gives you access to technical know-how, tried-and-true methods, and full support throughout the whole process of developing a product.

Partner with Yongsheng for Expert Plastic Mold Manufacturing Solutions

Picking the correct plastic mold maker has a big effect on the success of the project, the quality of the results, and the long-term efficiency of production. Yongsheng Hardware Plastic Product Co., Ltd. has been helping clients in the electronics, automotive, and consumer goods industries around the world for more than 30 years with precise mold fabrication and plastic injection molding.

Our manufacturing skills are very broad and cover the whole production process, from designing the mold to making a lot of them and doing secondary processing. In Dongguan, the famous "Town of Molds," our ISO9001:2015-certified facility has the most up-to-date mold-making tools and over 300 skilled workers who are committed to producing top-notch results.

Whether your project requires prototype mold development, high-volume production tooling, or specialized plastic injection capabilities, our experienced team provides technical guidance throughout the development process. Ready to discuss your plastic mold requirements with a trusted supplier? Contact us at sales@alwinasia.com to explore how Yongsheng's expertise can optimize your next manufacturing project.

References

1. Malloy, R.A. (2021). Plastic Part Design for Injection Molding: An Introduction. 3rd Edition. Society of Plastics Engineers.

2. Kalpakjian, S. & Schmid, S.R. (2020). Manufacturing Engineering and Technology. 8th Edition. Pearson Education.

3. Rosato, D.V., Rosato, M.G. & Rosato, D.P. (2019). Injection Molding Handbook. 4th Edition. Springer Science & Business Media.

4. Campbell, J. (2022). Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. 3rd Edition. Butterworth-Heinemann.

5. Johannaber, F. & Michaeli, W. (2021). Handbuch Spritzgießen: Handbook of Injection Molding. 3rd Edition. Carl Hanser Verlag.

6. ASM International Handbook Committee (2020). ASM Handbook Volume 15: Casting. 2nd Edition. ASM International Materials Park.