Selecting the Best Supplier for Custom Plastic Injection Molds in Russia

In the quickly advancing manufacturing scene of Russia, finding the right provider for custom plastic injection molds is vital for businesses aiming to remain competitive and inventive. The process of selecting a solid and gifted provider can be complex, including contemplations of specialized ability, generation capacity, quality guidelines, and cost-effectiveness. This web journal post points to direct producers and businesses through the perplexing process of choosing the best provider for custom plastic infusion molds in Russia. We'll investigate key components to consider, industry best practices, and how to assess potential providers to guarantee a fruitful association. By understanding the subtleties of the Russian showcase and the particular necessities of custom plastic infusion molding, companies can make educated choices that will emphatically affect their production processes and final products.

Evaluating Technical Capabilities and Experience

Assessing Mold Design Expertise

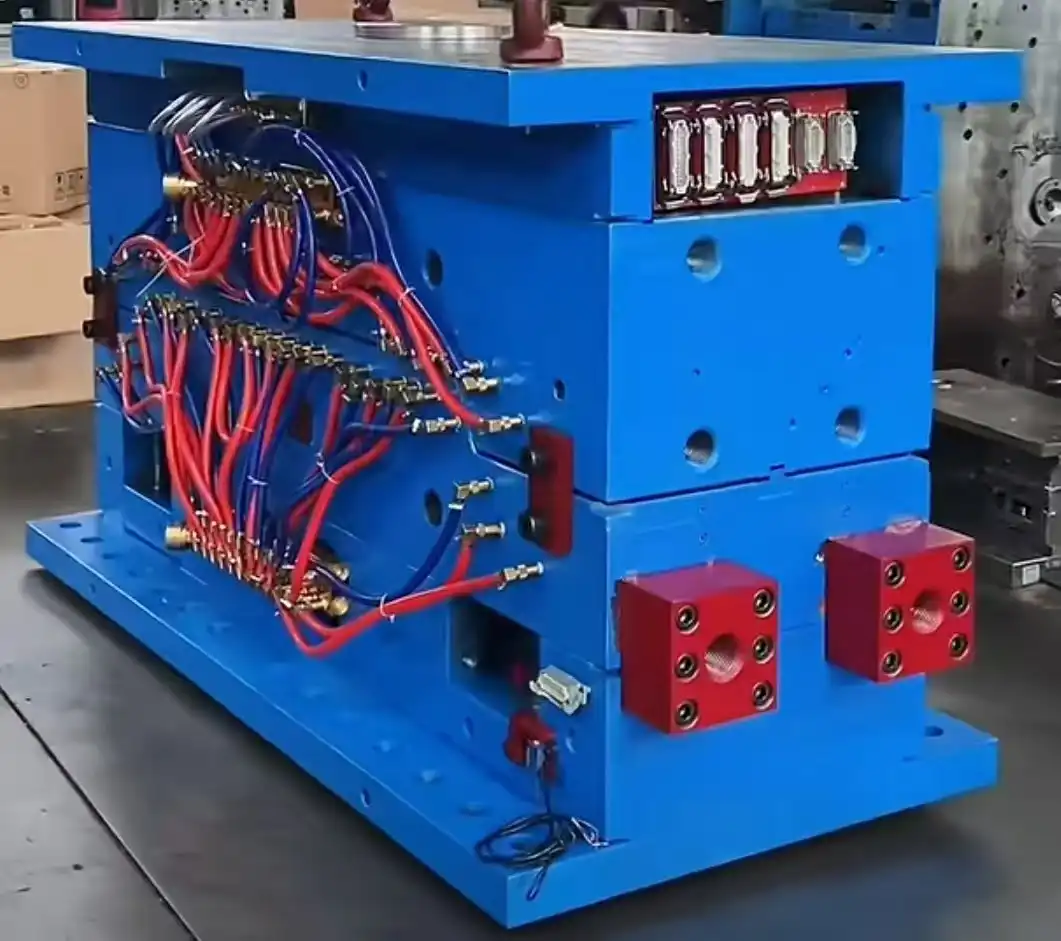

When selecting a provider for custom plastic infusion molds in Russia, it's vital to assess their form plan ability. A capable provider ought to illustrate an intensive understanding of complex shape plans, including multi-cavity molds, hot runner frameworks, and progressed cooling methods. They ought to be able to optimize plans for proficient generation, considering components such as fabric stream, cooling time, and portion discharge. See for providers who utilize cutting-edge CAD/CAM computer programs and reenactment instruments to foresee and resolve potential issues, some sometimes long-form generation starts. Also, survey their encounter with a wide range of plastics and their capacity to plan molds that suit distinctive fabric properties and shrinkage rates.

Analyzing Production Capabilities

The generation capabilities of a custom plastic injection molds provider in Russia are vital to guaranteeing timely and high-quality shape conveyance. Assess the supplier's apparatus and gear, including CNC machines, EDM hardware, and assessment instruments. A well-equipped office ought to have the capacity to handle different forms, sizes, and complexities. Ask about their generation capacity, lead times, and capacity to scale generation as required. It's moreover critical to survey their quality control measures all through the production process, including in-process assessments and final shape testing. See for providers who have actualized incline fabricating standards and ceaseless change strategies to upgrade productivity and diminish squander in their production processes.

Reviewing Past Projects and Client Testimonials

To gauge the unwavering quality and skill of a custom plastic infusion molds provider in Russia, audit their portfolio of past ventures and client tributes. Ask for case ponders or illustrations of molds they've created for businesses comparable to yours. Pay consideration to the complexity of the molds, the materials utilized, and the production volumes accomplished. Client tributes can give important bits of knowledge into the supplier's communication, problem-solving capacities, and, in general, client satisfaction. See for providers who have experience working with worldwide clients, as this can show their capacity to meet worldwide quality guidelines and explore cross-border operations. Moreover, consider coming to out to their references straightforwardly to pick up a more comprehensive understanding of their execution and reliability.

Quality Assurance and Certification Standards

ISO Certification and Quality Management Systems

When selecting a provider for custom plastic infusion molds in Russia, it's fundamental to prioritize those with ISO certification and vigorous quality administration frameworks. ISO 9001 certification illustrates a supplier's commitment to keeping up reliable quality benchmarks and continuous enhancement. See for providers who have actualized comprehensive quality administration frameworks that cover all perspectives of design, development, and testing. These frameworks ought to incorporate archived strategies, standard reviews, and worker preparation programs. A provider with a solid focus on quality confirmation is more likely to deliver custom plastic infusion molds that meet or surpass your details and perform dependably in production.

Material Testing and Traceability

Ensuring the quality and consistency of materials utilized in custom plastic injection molds is vital for long-term shape execution. Assess potential providers based on their fabric testing capabilities and traceability frameworks. See for providers who conduct intensive fabric testing, including chemical composition examination, hardness testing, and microstructure examination. A vigorous traceability framework ought to permit for the following of materials from receipt through production to final form conveyance. This is especially imperative for businesses with rigid quality requirements, such as car or therapeutic gadget manufacturing. Inquire potential providers approximately their fabric sourcing homes and whether they keep up connections with legitimate steel and alloy providers to guarantee reliable quality.

Mold Testing and Validation Procedures

The last organize of quality affirmation for custom plastic infusion molds includes comprehensive testing and approval methods. Ask approximately the supplier's shape testing capabilities, including their capacity to perform trial runs and create test parts. A solid provider ought to have offices to conduct flow stream analysis, cooling system efficiency tests, and cycle time optimization. See for providers who offer point-by-point shape approval reports, including dimensional exactness estimations, surface wrap-up assessments, and portion quality evaluations. Moreover, consider providers who give back amid the shape commissioning prepare at your office, guaranteeing smooth integration with your injection molding machines and production processes.

Cost Considerations and Long-term Value

Pricing Structure and Transparency

When assessing providers for custom plastic infusion molds in Russia, it's significant to get their estimating structure and guarantee transparency in all cost-related viewpoints. See for providers who give point-by-point citations, breaking down costs for plan, materials, labor, and any extra administrations. Be attentive of providers advertising altogether lower costs than the market normal, as this may show compromises in quality or hidden costs. A legitimate provider ought to be willing to examine their estimating technique and clarify any variations in fetched gauges. Consider the added up taken to a toll on proprietorship, including potential support and repair costs over the mold's lifetime. Providers who offer competitive estimating while keeping up high-quality benchmarks and giving comprehensive after-sales support are frequently recognized as the best value for custom plastic infusion molds.

Delivery Timelines and Reliability

The capacity to meet agreed-upon conveyance timelines is a basic factor in selecting a provider for custom plastic injection molds in Russia. Assess potential providers based on their track record of on-time conveyances and their capacity to handle surge orders when necessary. Ask around their venture administration forms and how they handle potential delays or unexpected challenges. A solid provider ought to have contingency plans in place and keep up open communication throughout the production prepare. Consider providers who offer real-time venture following or advanced upgrades, as this can help you oversee your generation plans more successfully. Keep in mind that whereas speedier conveyance times can be appealing, they should not come at the cost of quality or intensive testing methods for your custom plastic infusion molds.

After-Sales Support and Warranty

The long-term esteem of custom plastic infusion molds is altogether impacted by the quality of after-sales bolster and guarantee arrangements advertised by the provider. Explore the scope and length of guarantees given, paying attention to what is secured and any exclusions. See for providers who offer comprehensive bolster administrations, including investigating, upkeep direction, and repair services. Consider the accessibility of spare parts and the supplier's capacity to give speedy turnaround on repairs or adjustments. Providers who offer training for your staff on form support and ideal utilization can include impressive esteem, possibly extending the life of your molds and moving forward by and large production productivity. Assess the supplier's commitment to long-term associations and their readiness to give continuous specialized support as your generation's needs advance.

Conclusion

Selecting the best supplier for custom plastic injection molds in Russia requires careful consideration of technical capabilities, quality assurance practices, and long-term value propositions. By thoroughly evaluating potential suppliers across these key areas, manufacturers can forge partnerships that not only meet immediate production needs but also support future growth and innovation. Remember that the right supplier should offer a balance of expertise, quality, and cost-effectiveness, backed by reliable customer support and a commitment to continuous improvement. As the Russian manufacturing sector continues to evolve, choosing the right mold supplier can be a significant competitive advantage, enabling businesses to produce high-quality plastic components efficiently and cost-effectively.

For those seeking a reliable partner in custom plastic injection molds, consider Alwin Asia Limited, registered in Hong Kong, and its manufacturing arm, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience and ISO9001:2015 certification, Yongsheng offers comprehensive services from design to production. Located in Changan Town, Dongguan City—known as the Town of Molds—the company boasts a 6000 square meter facility and a workforce of over 300 employees. Their proximity to Shenzhen airports ensures convenient visits for international clients. Yongsheng prides itself on high-quality, cost-effective solutions, timely delivery, and strict client information protection. For inquiries, contact them at sales-c@alwinasia.com.

FAQ

Q: What are the key factors to consider when choosing a custom plastic injection mold supplier in Russia?

A: Key factors include technical capabilities, quality assurance practices, production capacity, cost structure, delivery reliability, and after-sales support.

Q: How important is ISO certification when selecting a mold supplier?

A: ISO certification, particularly ISO 9001, is crucial as it demonstrates a supplier's commitment to quality management and continuous improvement.

Q: What should I look for in a supplier's mold testing procedures?

A: Look for comprehensive testing, including mold flow analysis, cooling system efficiency tests, dimensional accuracy measurements, and part quality assessments.

Q: How can I evaluate a supplier's experience with custom plastic injection molds?

A: Review their portfolio of past projects, ask for case studies, and consider contacting their previous clients for references.

Q: What kind of after-sales support should I expect from a good mold supplier?

A: Expect comprehensive warranty coverage, troubleshooting assistance, maintenance guidance, repair services, and ongoing technical support.

References

1. Ivanov, S. (2021). "The State of Plastic Injection Molding Industry in Russia: Trends and Challenges." Russian Manufacturing Journal, 15(3), 78-92.

2. Petrov, A., & Smirnova, E. (2020). "Quality Management Systems in Russian Mold Manufacturing: A Comparative Study." International Journal of Production Research, 58(12), 3567-3582.

3. Kozlov, D. (2022). "Technological Advancements in Custom Plastic Injection Molds: A Russian Perspective." Journal of Materials Processing Technology, 300, 117345.

4. Volkova, N., & Sokolov, A. (2019). "Supplier Selection Criteria for High-Precision Molds in the Russian Automotive Industry." Supply Chain Management: An International Journal, 24(5), 631-647.

5. Fedorov, I. (2023). "Cost-Benefit Analysis of Advanced Mold Design Techniques in Russian Manufacturing." International Journal of Advanced Manufacturing Technology, 114(7), 2189-2205.

6. Kuznetsova, L., & Popov, V. (2021). "The Impact of Industry 4.0 on Custom Mold Manufacturing in Russia." Procedia Manufacturing, 51, 1873-1880.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer