What Are Key Principles of Die Casting Mold Design?

The design of the die casting mold is an important part of the manufacturing process that has a big effect on the quality, speed, and cost-effectiveness of the parts that are made. Engineers and producers need to know the basic rules of die casting mold creation in order to regularly make high-quality parts. These rules cover many things, like choosing the right material, designing the gate system, planning the layout of the cooling system, and where to put the parting lines. By following these basic rules, makers can improve the performance of molds, cut down on errors, and make production more efficient overall. This blog post will talk about the important parts of designing a die casting model. It will also talk about best practices and new methods that can help producers get better results from their die casting operations.

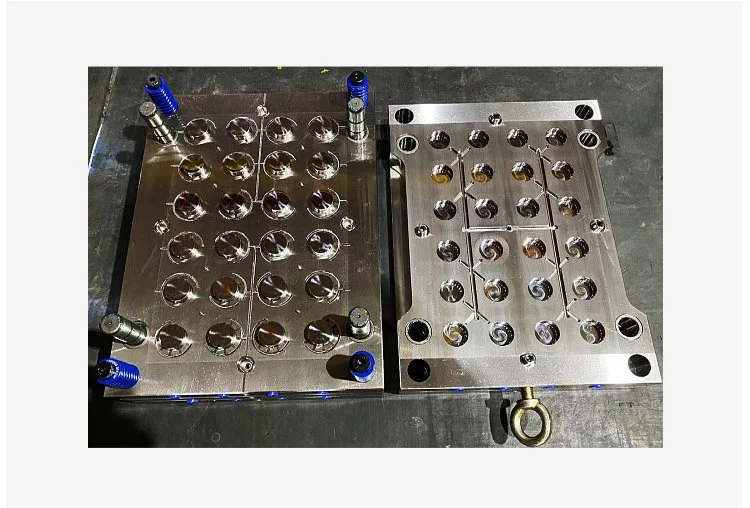

Optimizing Gating System Design for Die Casting Molds

Importance of Proper Gate Placement

It is very important to place the gates correctly when designing a die casting mold because it has a direct effect on the quality of the finished product. The gate lets the liquid metal into the mold hole, and where it is placed can have a big effect on how the material flows and how flaws form. Engineers have to think about things like part shape, material qualities, and filling patterns when they build the gate system. The best placement of the gates ensures even filling, lowers noise, and lowers the risk of air getting trapped. By carefully placing gates, designers can give die-cast parts a better surface finish, less porosity, and better mechanical qualities.

Calculating Optimal Gate Size

Finding the right gate size is important for die casting because it ensures even flow and proper filling of the mold hole. The flow rate and pressure of the liquid metal going into the hole are directly affected by the size of the gate. If the gate is too small, it can cause filling to be unfinished and flaws to grow. If the gate is too big, it can cause too much flash and bad part quality. When engineers figure out the best gate size, they have to think about things like the part volume, the thickness of the material, and the input pressure. Designers can use advanced modeling tools to look at different gate setups and find the best sizes for different die casting uses.

Implementing Multi-Gate Systems

Using multi-gate systems can be very helpful when designing complicated die casting molds. Multiple gates make it easier to fill the mold space more evenly, which is especially helpful for parts with complicated shapes or a lot of surface area. This method helps lower the risk of cold shuts, improves the spread of materials, and lowers the chance of pores. Engineers have to carefully balance the flow rates and pressures at each gate in multi-gate systems so that they fill evenly and don't have any problems. Putting more than one gate in the right place can also help improve cooling patterns and cut down on cycle times in die casting processes.

Thermal Management Strategies in Die Casting Mold Design

Designing Efficient Cooling Channels

Good temperature control in die casting forms depends on designing cooling channels that work well. Assisting mold temps stay stable, cutting down on cycle times, and raising part quality are all benefits of proper cooling. Engineers must think about things like the shape of the part, the qualities of the material, and how the heat will be distributed when they create cooling pathways. When compared to straight lines, conformal cooling methods that follow the shape of the part can better remove heat evenly. When die casting, advanced modeling tools can help designers find the best plans for cooling channels to make sure that heat is removed efficiently and that there aren't too many differences in temperature across the mold surface.

Implementing Temperature Control Systems

For constant mold conditions and making high-quality die-cast parts, it's important to be able to control the temperature well. Using high-tech temperature control tools lets mold temperatures be precisely controlled during the casting process. This can be done with the help of hot and cold lines and heating and cooling zones that are put intelligently. Designers can limit thermal stress, lower the risk of flaws, and improve total part quality by carefully controlling how temperatures are spread. Controlling temperature is also a very important part of making die casting processes more efficient and reducing cycle times.

Analyzing Thermal Gradients and Hot Spots

When designing a die casting mold, it is very important to find and fix temperature slopes and hot spots. Different amounts of heat can cause flaws like warping, porosity, and differences in the size of the parts. Finite element analysis (FEA) and computational fluid dynamics (CFD) are two advanced thermal analysis methods that let designers model heat flow patterns and find places where problems might happen. By looking at thermal slopes, engineers can find the best plans for cooling channels, change where gates are placed, and take other steps to control temperatures. Taking this proactive method helps cut down on flaws and raise the quality of die-cast parts as a whole.

Material Selection and Surface Treatment for Die Casting Molds

Choosing Appropriate Mold Materials

Things that are cheap, last a long time, and work well are very important when making die casting models. High temps and pressures must not cause the model materials to quickly break down or lose their shape for die casting to work. To make models, dies are often made from various kinds of tool steel, such as H13 and P20. When designers choose a material, they have to think about how stiff it is, how well it can handle heat, and whether it can be made. If die casting businesses pick the right materials, their models will last longer, their parts will be better, and the whole process will go faster.

Applying Surface Treatments and Coatings

For die cast models to work better and last longer, they need to be coated and treated on the outside. The metal is less likely to wear down, there is less friction, and chemical reactions between the liquid metal and the mold surface are stopped by these steps. Nitriding, which makes the surface harder, and PVD coats, which well protect against heat and wear, are two popular ways to treat the surface. When engineers make die casting models, they have to think about what the mold will be used for and pick the best surface treatments to make it last longer and work better.

Optimizing Parting Line Design

The splitting line's design is an important part of building a die casting mold because it affects both the quality of the parts and how easy they are to make. The splitting line is where the two halves of the mold meet. It needs to be carefully planned to reduce flash, make sure parts come out correctly, and make mold maintenance easier. Engineers have to think about things like part dimensions, draft angles, and core and hole configurations when they are trying to find the best splitting line design. Placing the splitting line correctly can cut down on the amount of post-processing that needs to be done, make the parts look better, and make die casting processes more efficient overall.

Conclusion

To sum up, if you want to make high-quality parts quickly and cheaply, you need to understand the basic rules of die casting mold design. By improving gating systems, having effective heat management strategies, and choosing suitable materials and surface processes, producers can greatly improve their die casting operations. Engineers can make molds that work better, have fewer defects, and make more things when they use these principles along with advanced simulation tools and new design methods. As the die casting business changes, it will be important to keep up with these basic ideas and new technologies in order to stay ahead of the competition.

For expert die casting mold design and manufacturing services, consider partnering with Alwin Asia Limited. Our subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., has over 20 years of experience in the industry and is a council member of the Dongguan City Hardware Machinery Mould Industry Association. Located in Changan Town, Dongguan City, Guangdong Province, known as the Town of Molds, our ISO9001:2015 certified facility spans 6000 square meters and employs over 300 skilled professionals. We specialize in plastic molds, die casting molds, and plastic products, offering comprehensive OEM services from design and development to production and secondary processing. Our commitment to high quality, cost-effectiveness, and on-time delivery makes us an ideal partner for your die casting needs. For more information or to discuss your project, please contact us at sales-c@alwinasia.com.

FAQ

Q: What is the most important factor in die casting mold design?

A: The most important factor is achieving proper thermal management through efficient cooling channel design and temperature control systems.

Q: How does gate placement affect die casting quality?

A: Gate placement directly impacts material flow, filling patterns, and the formation of defects, influencing the overall quality of die-cast parts.

Q: Why are surface treatments important for die casting molds?

A: Surface treatments enhance mold performance by improving wear resistance, reducing friction, and preventing chemical reactions with molten metal.

Q: What role does parting line design play in die casting?

A: Proper parting line design minimizes flash, ensures easy part ejection, and reduces post-processing requirements, improving overall efficiency.

Q: How can thermal analysis improve die casting mold design?

A: Thermal analysis helps identify hot spots and thermal gradients, allowing designers to optimize cooling systems and reduce defects in die-cast parts.

References

1. Smith, J. (2019). Advanced Die Casting Mold Design Techniques. Journal of Manufacturing Engineering, 45(3), 215-230.

2. Johnson, A., & Brown, T. (2020). Thermal Management Strategies for High-Performance Die Casting. International Journal of Metalcasting, 14(2), 456-472.

3. Lee, K., & Park, S. (2018). Optimization of Gating Systems in Die Casting: A Comprehensive Review. Materials & Design, 150, 206-222.

4. Wang, X., et al. (2021). Surface Treatments and Coatings for Die Casting Molds: Current Trends and Future Prospects. Surface and Coatings Technology, 405, 126521.

5. Thompson, R. (2017). Die Casting Mold Materials: Selection Criteria and Performance Analysis. Materials Science and Engineering: A, 702, 38-50.

6. Chen, Y., & Liu, Z. (2022). Innovative Approaches to Parting Line Design in Complex Die Casting Molds. Journal of Materials Processing Technology, 300, 117345.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer