What certifications do automotive parts require?

In the automobile industry, ensuring component reliability, quality, and safety is essential. Vehicle performance and safety are greatly influenced by automotive parts; thus, certifications are a vital element of the production and distribution process. The components' compliance with certain standards and rules established by different regulatory agencies and industry associations is ensured by these certificates. Automotic parts go through extensive testing and certification procedures to make sure they satisfy the exacting standards of the automobile industry, whether they are safety-critical parts or accessories that improve performance. The many certifications needed for car components, their significance, and how they improve the general caliber and security of automobiles on the road will all be covered in this article.

Safety Certifications for Automotive Parts

Federal Motor Vehicle Safety Standards (FMVSS)

Developed by the National Highway Traffic Safety Administration (NHTSA) in the United States, the Federal Motor Vehicle Safety Standards (FMVSS) are a collection of rules. These guidelines make sure that different vehicle systems and parts fulfill the bare minimum of safety criteria. Automotive component manufacturers are required to abide by FMVSS rules in order to sell their goods in the United States. Airbags, lighting fixtures, and braking systems, for instance, must adhere to certain FMVSS regulations. The safety of automobiles and their passengers depends on adherence to these regulations. For automotive parts manufacturers to prove that their goods meet or beyond FMVSS regulations, they must go through stringent testing and certification procedures.

European Union Type Approval

To legally be sold and used in automobiles, automotive parts in the EU need to have Type Approval certification. The components' compliance with EU safety and environmental requirements is guaranteed by this certification. In order to confirm that automotive parts and automotic parts comply with applicable EU rules and regulations, the Type Approval procedure includes testing and inspection. For example, among the various vehicle items that need EU Type Approval are exhaust systems, lighting components, and automotive parts. Manufacturers are required to submit their goods for testing at recognized labs and to provide proof of conformity. Following approval, the automotive parts are assigned a distinct Type Approval number that permits their sale and usage throughout the European Union.

International Organization for Standardization (ISO) Certifications

The quality and uniformity of automobile parts are significantly ensured by ISO certifications. IATF 16949, the current version of ISO/TS 16949, is a standard designed especially for the automobile sector. For suppliers and producers of car components, this accreditation focuses on quality management systems. Automotive component design, development, manufacture, and installation are only a few of the many facets of the production process that are included. Following ISO guidelines shows that a firm is dedicated to quality and ongoing development. For automotive parts manufacturers to be competitive in the worldwide market, it is imperative that they invest in ISO certifications, since many automakers demand that their suppliers receive them.

Performance Certifications for Automotive Parts

Society of Automotive Engineers (SAE) Standards

A vast array of standards for automotive systems and components is created and maintained by the Society of Automotive Engineers (SAE). These standards address a number of performance-related topics, such as compatibility, durability, and dependability. Worldwide, automakers and suppliers have embraced and universally accepted SAE standards. For instance, automobile fasteners must adhere to SAE strength categories, and engine fluids must fulfill SAE viscosity ratings. Manufacturers of automotive parts often test their goods in accordance with SAE guidelines and get certificates to prove conformity. Both producers and customers may be reassured by these certificates that the parts fulfill performance standards recognized by the industry.

Automotive Aftermarket Suppliers Association (AASA) Certification

Certification methods are offered by the Automotive Aftermarket Suppliers Association (AASA) for aftermarket auto **and automotic parts**. These certifications assure replacement parts used in car repair and maintenance are of a high quality and operate well. AASA certifications apply to many car items, including electrical systems, braking parts, automotic parts, and filters. Premium aftermarket components that meet or exceed original equipment specifications are produced by manufacturers that have earned AASA certification. These certifications foster trust between consumers and repair companies by ensuring that the aftermarket components that consumers purchase will operate correctly and dependably.

Original Equipment Manufacturer (OEM) Certifications

Vehicle manufacturers provide suppliers of automotive components with special authorization known as Original Equipment Manufacturer (OEM) certifications. These certifications guarantee that the components fulfill the precise requirements and quality criteria set out by the original equipment manufacturer for use in their automobiles. OEM certifications often include stringent testing and validation procedures to confirm the parts' functionality, robustness, and suitability for a certain vehicle type. For example, in order to be utilized as original equipment or authorized replacement parts, brake pads, alternators, and engine components may need OEM certificates. Although getting OEM certifications may be difficult and time-consuming, doing so gives car parts producers a considerable competitive edge and gives them access to profitable supply agreements with big automakers.

Environmental Certifications for Automotive Parts

Environmental Protection Agency (EPA) Certifications

The Environmental Protection Agency (EPA) in the United States requires certain automotive parts to obtain certifications related to emissions and environmental impact. These certifications are particularly important for components that affect vehicle emissions, such as catalytic converters, fuel systems, and engine control modules. EPA certifications ensure that automotive parts comply with emissions standards and contribute to reducing the environmental impact of vehicles. Manufacturers must submit their products for testing and provide documentation to demonstrate compliance with EPA regulations. Obtaining EPA certifications is crucial for automotive parts manufacturers to sell their products in the US market and contribute to the overall goal of reducing vehicle emissions and improving air quality.

Restriction of Hazardous Substances (RoHS) Compliance

The Restriction of Hazardous Substances (RoHS) directive, originally implemented in the European Union, has become a global standard for reducing the use of hazardous materials in electronic and electrical components. In the automotive industry, RoHS compliance is essential for many electronic parts, including sensors, control units, infotainment systems, and automotic parts. Automotive parts manufacturers must ensure that their products do not contain restricted substances such as lead, mercury, and cadmium above specified limits. RoHS compliance is verified through material analysis and documentation, with manufacturers often obtaining third-party certifications to demonstrate their commitment to environmental responsibility. As the automotive industry continues to incorporate more electronic components, RoHS compliance becomes increasingly important for ensuring the safety and sustainability of vehicles.

End-of-Life Vehicle (ELV) Directive Compliance

In order to lessen the environmental effect of cars that are approaching the end of their useful lives, the European Union created the End-of-Life Vehicle (ELV) Directive. Automakers are impacted by this rule since it mandates that they develop and manufacture components that are readily recyclable or reusable. Complying with the ELV Directive entails reducing the use of hazardous materials, enhancing component recyclability, and disclosing material composition. In order for auto parts manufacturers to sell their goods in the EU market, the ELV Directive mandates that they acquire certificates or declarations of compliance. This certification procedure encourages the creation of more environmentally friendly and sustainable vehicle components by encouraging innovation in material selection and design.

Conclusion

Performance, safety, and adherence to environmental standards are just a few of the reasons why auto parts and automatic parts must be certified. Safety requirements like FMVSS and EU Type Approval, OEM certifications, and SAE performance certificates are necessary to guarantee the reliability and quality of automotive components. The industry's commitment to sustainability and effect reduction is shown by environmental compliance certifications such as EPA, RoHS, and ELV. Additional certifications will be needed as automotive technology advances to ensure that vehicles on the road meet the highest standards for performance, safety, and environmental responsibility.

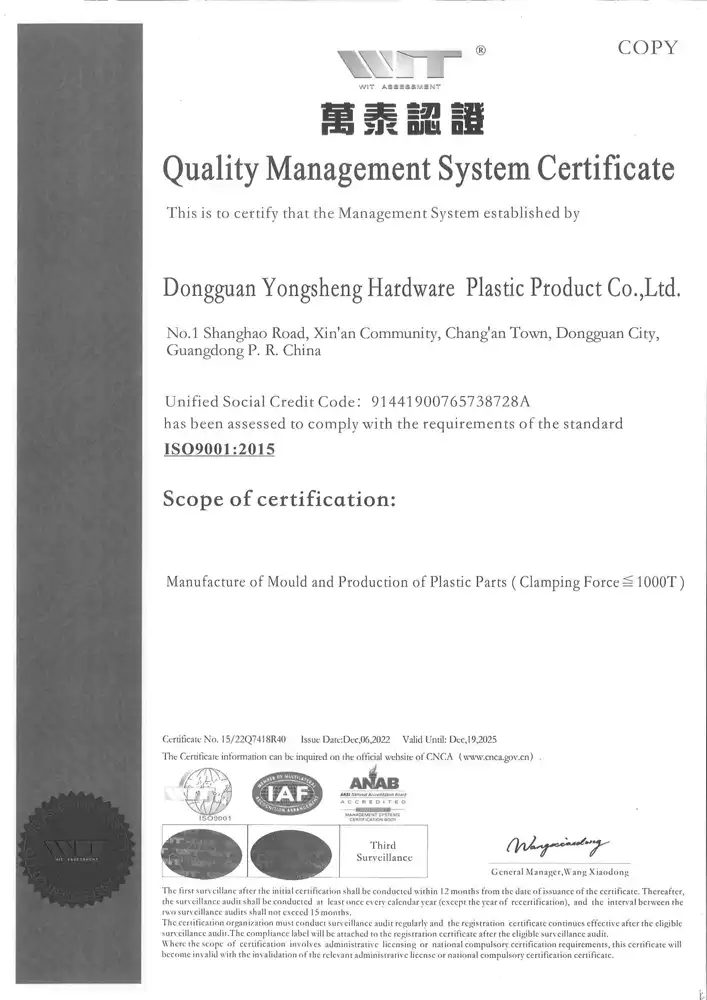

For high-quality automotive parts and components, consider Alwin Asia Limited, registered in Hong Kong. Our manufacturing facility, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., has over 20 years of experience in plastic molds, die casting molds, and plastic products. Located in Chang'an Town, Dongguan City, Guangdong Province, we are ISO9001:2015 certified and offer comprehensive services from design to production. Our factory is conveniently located near Shenzhen airports, making it easy for international clients to visit. We pride ourselves on high quality, competitive pricing, on-time delivery, and strict client information protection. For inquiries, please contact us at sales@alwinasia.com.

FAQ

Q: Why are certifications important for automotive parts?

A: Certifications ensure that automotive parts meet safety, performance, and environmental standards, guaranteeing quality and reliability for consumers and manufacturers.

Q: What is the difference between FMVSS and EU Type Approval?

A: FMVSS is a US standard for vehicle safety, while EU Type Approval is a European certification system for automotive parts compliance with EU regulations.

Q: Are ISO certifications mandatory for automotive parts manufacturers?

A: While not always mandatory, ISO certifications are often required by automakers and demonstrate a commitment to quality management and continuous improvement.

Q: How do SAE standards benefit consumers?

A: SAE standards ensure that automotive parts meet industry-accepted performance criteria, providing consumers with reliable and high-quality components.

Q: What is the purpose of RoHS compliance in automotive parts?

A: RoHS compliance aims to reduce the use of hazardous materials in electronic components, promoting environmental responsibility and safety in the automotive industry.

References

1. National Highway Traffic Safety Administration. (2021). "Federal Motor Vehicle Safety Standards and Regulations."

2. European Commission. (2020). "Vehicle Type-Approval in the EU."

3. International Automotive Task Force. (2019). "IATF 16949:2016 - Quality management system requirements for automotive production."

4. Society of Automotive Engineers. (2021). "SAE Standards for Automotive Applications."

5. Environmental Protection Agency. (2020). "Regulations for Emissions from Vehicles and Engines."

6. European Commission. (2021). "End-of-life vehicles - reuse, recycling and recovery, statistics."

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer