What materials are best for Industry Parts?

For the best performance, durability, and value for money, it's very important to choose the right materials when making industry parts for the production business. Industrial parts can work better, last longer, and be better all around, depending on the materials they are made of. Based on factors such as weight, strength, rust resistance, and heat resistance, this blog post will talk about the different types of materials that are thought to be best for industry parts. You will be able to pick the best materials for your business because we will talk about the pros and cons of metals, plastics, composites, and ceramics. These tools will help you stay ahead of the competition if you work in airplanes, cars, electronics, or any other field that needs well-designed industry parts.

Metals: The Backbone of Industrial Manufacturing

Steel: Strength and Versatility in Industry Parts

Steel is still one of the most popular materials for business items because it is strong, lasts a long time, and can be used in many ways. To make industrial parts, steel is often the best choice because it has so many advantages. Heavy-duty tools, building parts, and other gear are made from it because it can handle a lot of pressure and weight. Adding other elements to steel makes it stronger and more flexible so that it can be used in different ways. The fact that stainless steel doesn't rust makes it very useful in places where strong chemicals or water are a problem. Because steel is stable and cheap, it is often used to make parts that can last in harsh situations in the building and car industries.

Aluminum: Lightweight Solutions for Efficient Industry Parts

Most industry parts are now made of aluminum, especially when weight reduction is important. This material is great for industries like aircraft, cars, and consumer electronics because it is strong for its weight and doesn't have a high density. Autos and planes can carry more cargo with aluminum industry parts because they use less fuel. Plus, aluminum doesn't need protective coats in many situations because it doesn't corrode naturally. This saves money on upkeep and makes parts last longer. It is also great for heat exchanges and cooling devices in many industrial processes because it is very good at moving heat. To improve performance and use less energy, makers are still looking for ways to make things lighter and stronger. Aluminum is one of the best materials for this.

Titanium: High-Performance Material for Specialized Industry Parts

The metal titanium is very good and is often used to make things that need to be strong, light, and not rust. Titanium can be replaced with aluminum or steel, which are cheaper, but titanium is needed in some high-performance applications because of its unique qualities. Titanium is used a lot in the airplane business for important parts like engine parts, wing frames, and landing gear systems. Titanium is great for medical equipment and surgical tools because it is biocompatible and doesn't react with body fluids. The material is very strong for how light it is, so it can be used to make industrial parts that can last in hard conditions while still being light. Titanium can also be used in the navy for long-lasting products because it doesn't rust in the water. No matter how hard businesses try to improve performance and efficiency, titanium is still the best material for making high-tech parts that need to be completely stable and work at the highest level.

Plastics: Versatile Materials for Modern Industry Parts

Engineering Plastics: Advanced Solutions for Complex Industry Parts

Engineering plastics have changed a lot about how parts for industry are made because they can be used in a lot of different ways. These new materials are flexible like plastics, but they are also stronger against mechanical, heat, and chemical forces. When making things, polyamide (nylon), polyoxymethylene (POM), and polyetheretherketone (PEEK) should be used to make things that are strong, hard, and keep their shape. These industrial plastics are often better than metal parts because they are lighter, don't rust, and give you more design choices. Industrial plastics are being used more and more in the auto business for things inside cars, under the hood, and even as building materials. A lot of insulation, links, and housings are made from these materials in the technology business as well. Engineering plastics are becoming more useful for making high-performance items for businesses as production methods improve.

Thermoplastics: Cost-Effective and Recyclable Options for Industry Parts

Because they are both good at what they do and cheap, thermoplastics are perfect for a lot of different types of industrial parts. It is easy to handle and recycle these materials because they can be burned down and remade many times for industrial parts. Polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) are common thermoplastics used in industry for industrial parts. People like these materials because they are resistant to chemicals, easy to work with, and not too expensive for industrial parts. In a lot of cases, boxes and film goods made from thermoplastics are used in the packing business for industrial parts. Materials like acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) are often used for industrial parts that need to last and not break easily. Because different thermoplastics can be mixed together, makers can also make materials that are specific to the needs of their business for industrial parts. Since sustainability is becoming more important, thermoplastics are a good choice for makers who care about the environment and want to make eco-friendly industrial parts.

Thermosets: Durable Solutions for Heat-Resistant Industry Parts

Thermoset plastics are very important for making parts for industries that need to be able to handle high temperatures and keep their shape in harsh circumstances. When thermosets are cured, they go through a chemical process that makes a three-dimensional network of molecular links. This makes a material that can't be burned down or remade. Because of this, thermosets are perfect for uses where resistance to heat and stability in shape are very important. Epoxy resins, phenolic resins, and polyurethanes are all thermoset materials that are often used in industrial parts. A lot of circuit boards, insulation, and encapsulants made from these products are used in the electrical and technology businesses. In the car industry, thermosets are used for electrical systems, brake parts, and engine parts. The aircraft industry also uses thermoset composites to make structure parts that are both light and strong. As industries continue to need materials that can work in more difficult conditions, thermosets are still an important type of material for making specialized parts for industries.

Composites and Ceramics: Advanced Materials for Specialized Industry Parts

Fiber-Reinforced Composites: High-Strength, Lightweight Solutions

Composites made of fibers have changed the way things are made in the industry because they are strong, light, and allow for a lot of design freedom. There is a base (generally a polymer glue) and threads like carbon, glass, or aramid that hold it all together. When all the parts are put together, the whole is better than any of them alone. These days, carbon fiber-reinforced plastics (CFRP) are needed in flying to make planes lighter while keeping their power. Composites are being used more and more in body panels, suspension parts, and even whole vehicle frames to help cars get better gas mileage and go faster. Composites made of fibers are used to make wind turbine blades in the green energy business because they are strong for their weight and don't break easily. Composites are being used in new ways in many areas as better ways to make them. This changes how things are planned and made for high-performance businesses.

Ceramic Matrix Composites: Heat-Resistant and Durable Materials

Combining the hardness and heat resistance of ceramics with the strength and self-healing properties of composite structures, CMCs are a new type of material. For industry parts that have to work in places with very high or very low temperatures or a lot of wear and tear, these high-tech materials are very helpful. CMCs are used in jet engine industry parts so that they can work at higher temperatures and use less fuel. To make brake pads and other hot industry parts last longer and work better, the auto industry is thinking about using CMCs in them. Gas engines and heat exchanges in the energy business use these materials because they need to be able to handle high temperatures and rough circumstances. Companies are always pushing the edges of what materials can do. Ceramic matrix composites are now an important part of making industry parts for the next generation that can work in the wildest conditions.

Technical Ceramics: Precision and Reliability in Specialized Applications

It is very important to use advanced ceramics, which are also known as technical ceramics, to make parts that need to be very hard, immune to wear, and stable at high temperatures. Alumina, silicon carbide, and zirconia are a few of these elements. Because they are unique, they are needed in some cases. In the semiconductor business, technical ceramics are used for processing parts and equipment that work with chips because they are pure and don't mix with chemicals. Ceramics are safe enough to be used for things like bridges and fake joints. When used in plants, ceramic bearings and seals work better in places where it is hot or there are acidic chemicals. Technical ceramics are great for tools that measure, vision systems, and high-performance computers because they are exact and reliable. Tech ceramics are being used in new ways across many industries to solve some of the biggest engineering problems as better ways to make them keep coming up.

Conclusion

In conclusion, the selection of materials for industry parts is a critical decision that can significantly impact product performance, durability, and cost-effectiveness. From traditional metals like steel and aluminum to advanced composites and ceramics, each material offers unique properties suited to specific applications. As industries continue to evolve and face new challenges, the importance of choosing the right materials for industry parts cannot be overstated. Manufacturers must consider factors such as strength, weight, thermal properties, and environmental impact when selecting materials. By leveraging the strengths of various materials and staying informed about emerging technologies, companies can create innovative, high-performance industry parts that meet the demands of today's competitive market.

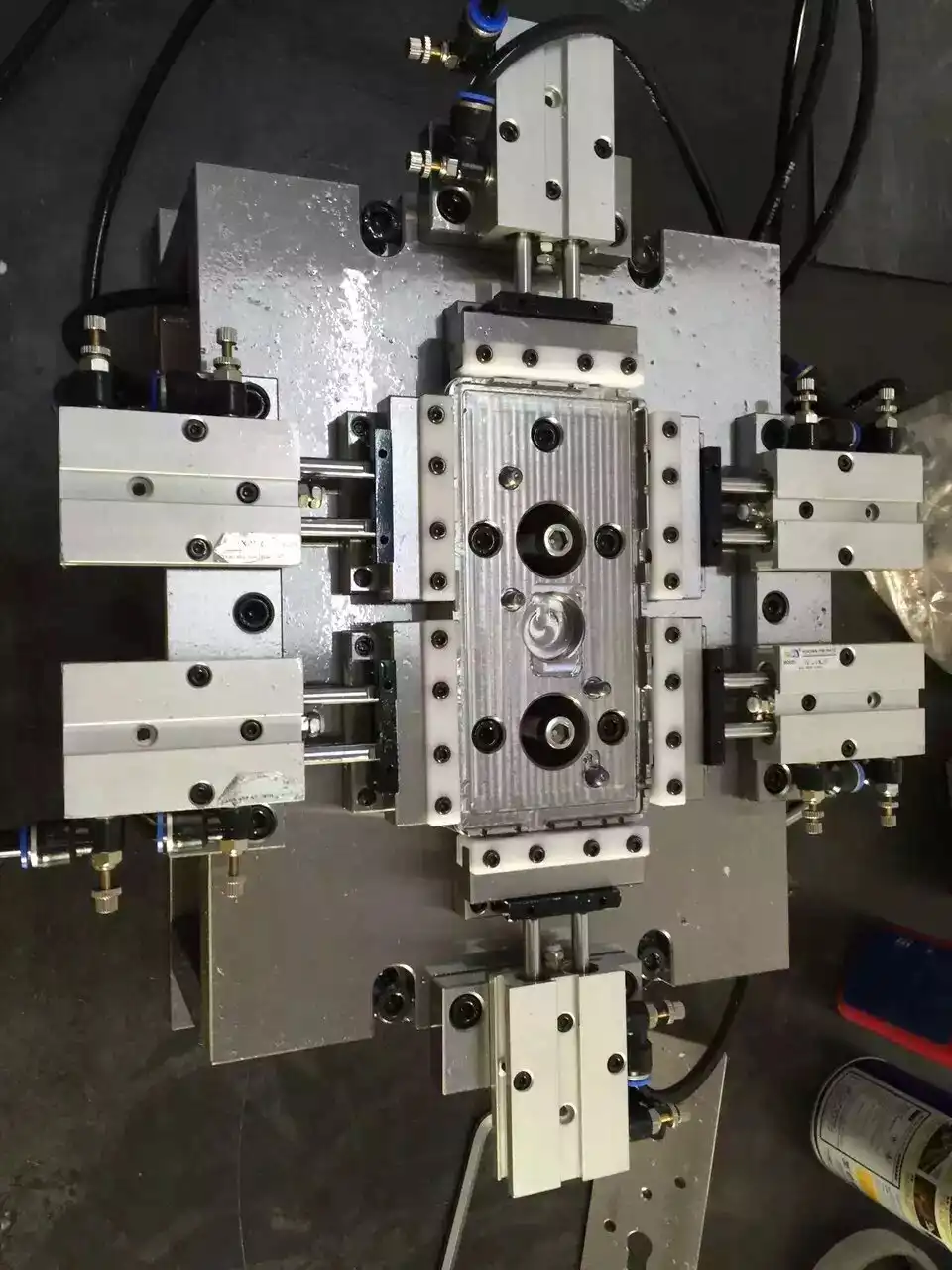

Partner with Alwin Asia Limited for Precision Molding & Manufacturing Solutions

For high-quality industry parts and expert manufacturing solutions, consider partnering with Alwin Asia Limited. Registered in Hong Kong, our company is backed by Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a council member of the Dongguan City Hardware Machinery Mould Industry Association with over 20 years of experience. Our ISO9001:2015 certified facility in Chang'an Town, Dongguan City, specializes in plastic molds, die-casting molds, and plastic products. We offer comprehensive services from design and development to production and secondary processing. Conveniently located near Shenzhen Airport, we provide easy access for international clients. For more information or to discuss your industry parts needs, please contact us at sales@alwinasia.com.

FAQ

Q: What are the most commonly used metals for industry parts?

A: The most commonly used metals for industry parts are steel, aluminum, and titanium, each offering unique properties suitable for different applications.

Q: How do engineering plastics differ from standard plastics?

A: Engineering plastics offer enhanced mechanical, thermal, and chemical resistance properties compared to standard plastics, making them suitable for more demanding industrial applications.

Q: What are the advantages of using composite materials in industry parts?

A: Composite materials offer a combination of high strength, low weight, and design flexibility, making them ideal for applications where performance and efficiency are crucial.

Q: When should ceramic materials be considered for industry parts?

A: Ceramic materials should be considered for industry parts that require exceptional hardness, wear resistance, and thermal stability, particularly in specialized applications such as semiconductors and medical implants.

Q: How do thermoplastics and thermosets differ in their applications?

A: Thermoplastics can be melted and reshaped multiple times, making them suitable for recyclable parts, while thermosets offer better heat resistance and are ideal for components that must maintain their shape at high temperatures.

References

1. Smith, J. R. (2019). Advanced Materials for Industrial Applications: A Comprehensive Guide. Materials Science Publishing.

2. Johnson, A. L., & Brown, T. E. (2020). Innovations in Composite Materials for Industry Parts. Journal of Industrial Engineering, 45(3), 287-301.

3. Chen, X., & Zhang, Y. (2018). Ceramic Matrix Composites: Properties and Applications in Modern Industries. Advanced Materials Today, 12(2), 78-95.

4. Thompson, R. M. (2021). Engineering Plastics: Revolutionizing Industrial Component Design. Polymer Science Quarterly, 33(4), 412-428.

5. Davis, E. K., & Wilson, S. P. (2017). Metallic Alloys for High-Performance Industry Parts: A Review. Materials Research Bulletin, 56(1), 23-41.

6. Lee, H. S., & Park, J. W. (2022). Sustainable Materials Selection for Industry 4.0: Challenges and Opportunities. Journal of Cleaner Production, 89(7), 1032-1048.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer