What surface treatments improve mold manufacture durability?

For people who make molds, durability is very important because it can greatly affect the speed, quality, and cost-effectiveness of production. Treatment of the surfaces can make molds last longer and work better. This is done to see if the models are still correct after many uses. In this blog post, a number of different methods are discussed for making the outside of molds last longer. In it, they're used for, how to be used, and the newest things that have happened in the area are explained. Mold makers and producers can use these tips to make smart choices that will help them make better goods, spend less on upkeep, and process better. Many mold-making businesses are changing because of new, useful ways to make surfaces. We will examine all of them, including new and old ways to use technology.

Advanced Coatings for Enhanced Mold Longevity

Physical Vapor Deposition (PVD) Coatings

Physical Vapor Deposition (PVD) layers have changed the way molds last for a long time. Thin layers of hard materials are deposited onto the mold surface using this advanced surface treatment method. This creates a protected layer that makes the mold much less likely to wear down and increases its resistance to friction. Mold makers use PVD finishes to make their tools last longer, especially when they are used in high-stress situations. Because the process lets mold makers precisely control the coating's thickness and make-up, the treatment can be made to fit specific needs. PVD coats stick very well to the base, so they protect for a long time even in tough circumstances. Mold makers can get better surface roughness, less wear, and better rust protection by using PVD coats. This can lead to higher efficiency and lower upkeep costs in the long run.

Chemical Vapor Deposition (CVD) Coatings

As another improved surface process that makes mold manufacturing last longer, Chemical Vapor Deposition (CVD) coats are used. Chemical reactions place thin films on the mold surface in this process, making a very thick and uniform layer. As a result of their high strength, resistance to wear, and temperature stability, CVD coatings are very popular among mold makers. The method lets complicated metals and combinations be used, giving mold makers many choices to solve specific problems. CVD coatings work great in high-temperature situations and protect molds using them in harsh settings very well against chemical attack. Utilizing CVD coatings in their production methods, mold makers can increase product quality, decrease tool downtime, and make tools last longer.

Thermal Spray Coatings

Due to their flexibility and ability to make things last longer, thermal spray paints have become very popular in the mold-making business. Melting or almost-melting materials are sprayed onto the mold surface in this method for treating the surface. This forms a protected layer that sticks by mechanical bonding. There are many materials that mold makers can use to get the qualities they want. These include metals, clay, and plastics. There are many mold uses that can use thermal spray coats because they are good at resisting wear, protecting against rust, and keeping heat in. So that work doesn't have to stop too often, the process makes it easy to apply and fix things quickly. Companies that make molds can greatly increase the quality of their products, lower the cost of upkeep, and make their tools last longer by using thermal spray coats.

Surface Hardening Techniques for Improved Wear Resistance

Nitriding

Nitriding is a common way to make surfaces stiffer, and it works very well to make molds last longer. Around the mold, nitrogen is spread out and strengthens the material on top. People who make molds like nitriding because it doesn't change the material's basic properties. This process makes it less likely to rust, less likely to rub against other things, and more resistant to wear. Because nitriding can be used on steel, aluminum, and other metals, mold makers have a lot of choices. This method works especially well for making injection molds, die-casting molds, and extruder dies last longer. The tools that mold makers use last longer, stay the same size, and need less maintenance when they nitride them. Things will work better and cost less in the long run through this.

Carburizing

For molds to last longer, another important way in mold manufacture to make the surface stiffer is to carburize it. Carbon is mixed into the surface of the mold material, which is usually steel, to make a hard layer that won't wear down. This keeps the core tough and bendable. To make the surfaces of their tools better, mold makers use carburizing in mold manufacture. This is especially useful when the tools need to be strong against pressure and wear. The treatment toughens up the surface so it doesn't wear down as easily and can support more weight. Forms used for tough jobs, like casting dies and pressing tools, respond best to carburizing in mold manufacture. Mold makers can make tools last longer, have less downtime, and make better goods overall by using carburizing in their work in mold manufacture. People will be pleased, and they will make more money.

Induction Hardening

Induction hardening is a highly efficient surface treatment technique that significantly improves mold manufacture durability. This process involves rapidly heating the mold surface using electromagnetic induction, followed by quenching to create a hard, wear-resistant layer. Mold makers appreciate induction hardening for its ability to selectively treat specific areas of the mold, providing targeted improvements in wear resistance and durability. The treatment results in increased surface hardness, improved fatigue strength, and enhanced dimensional stability. Induction hardening is particularly effective for large molds and complex geometries, making it a versatile option for mold manufacturers. By implementing induction hardening, mold makers can achieve longer tool life, reduced maintenance requirements, and improved overall product quality, ultimately leading to increased productivity and cost-effectiveness in their manufacturing processes.

Surface Texturing and Finishing for Enhanced Performance

Laser Texturing

As of now, laser etching is the most cutting edge way to treat surfaces. It has made plastic much more durable and helpful. Precision lasers are used to make designs and shapes on the mold's surface that are very detailed. This makes the mold look better and work better. Laser finishing makes it easier for molds to release parts. It also lowers friction and improves the quality of made parts in general. Makers of molds can exactly control the shape of the surface with this method, which lets them create layers that work well for certain purposes. Without laser engraving, molded goods would not look as good, cycle times would be longer, and the molding process would not work as well overall. By using laser finishing in their production methods, mold makers can make better parts with less maintenance and make their customers happy.

Polishing and Lapping

Polishing and cutting are important surface finishing methods in mold manufacture that are very important for making molds last longer and work better. In these steps in mold manufacture, the material on the mold surface is carefully removed to make the finish smooth and of high quality. Mold makers use sanding and lapping in mold manufacture to make the surfaces of their tools better, cut down on friction, and make made parts look better overall. The processes in mold manufacture make the surface finish better, cut down on wear, and improve the release qualities. For things like optical molds and precise parts in mold manufacture that need high-quality surface finishing, polishing and cutting work especially well. Mold manufacture can get longer tool lives, better part quality, and less upkeep needs by using these methods. This will eventually lead to higher productivity and customer happiness in their manufacturing processes.

Electropolishing

Molds last longer and work better with electropolishing, a better way to finish the surface. When you use an electrolytic way to carefully remove material from the mold surface, you get a better finish that is smooth and bright. Electropolishing is helpful for mold makers because it makes metals less likely to rust, improves the quality of the surface, and lowers friction. It's easier to clean and maintain because this process makes the surface smooth and even. Molds used in industries with strict cleanliness rules, like food and medicine preparation, work well after being electropolished. Electrical cleaning helps mold makers make better products, keep customers happy, and make the market more competitive.

Conclusion

Surface treatments are a key part of mold manufacture to make molds last longer, which is good for both the people who make the molds and the people who use them. Surface stiffening methods like nitriding and carburizing, as well as modern finishes like PVD and CVD, make molds last a lot longer, cost a lot less to maintain, and make the quality of the product better overall in mold manufacture. Texturing and finishing the surface of the mold improves its performance even more in mold manufacture, making it easier to release and look better. Mold makers and manufacturers need to keep up with these new surface processes in mold manufacture as technology keeps getting better in order to stay competitive in an industry that is always changing.

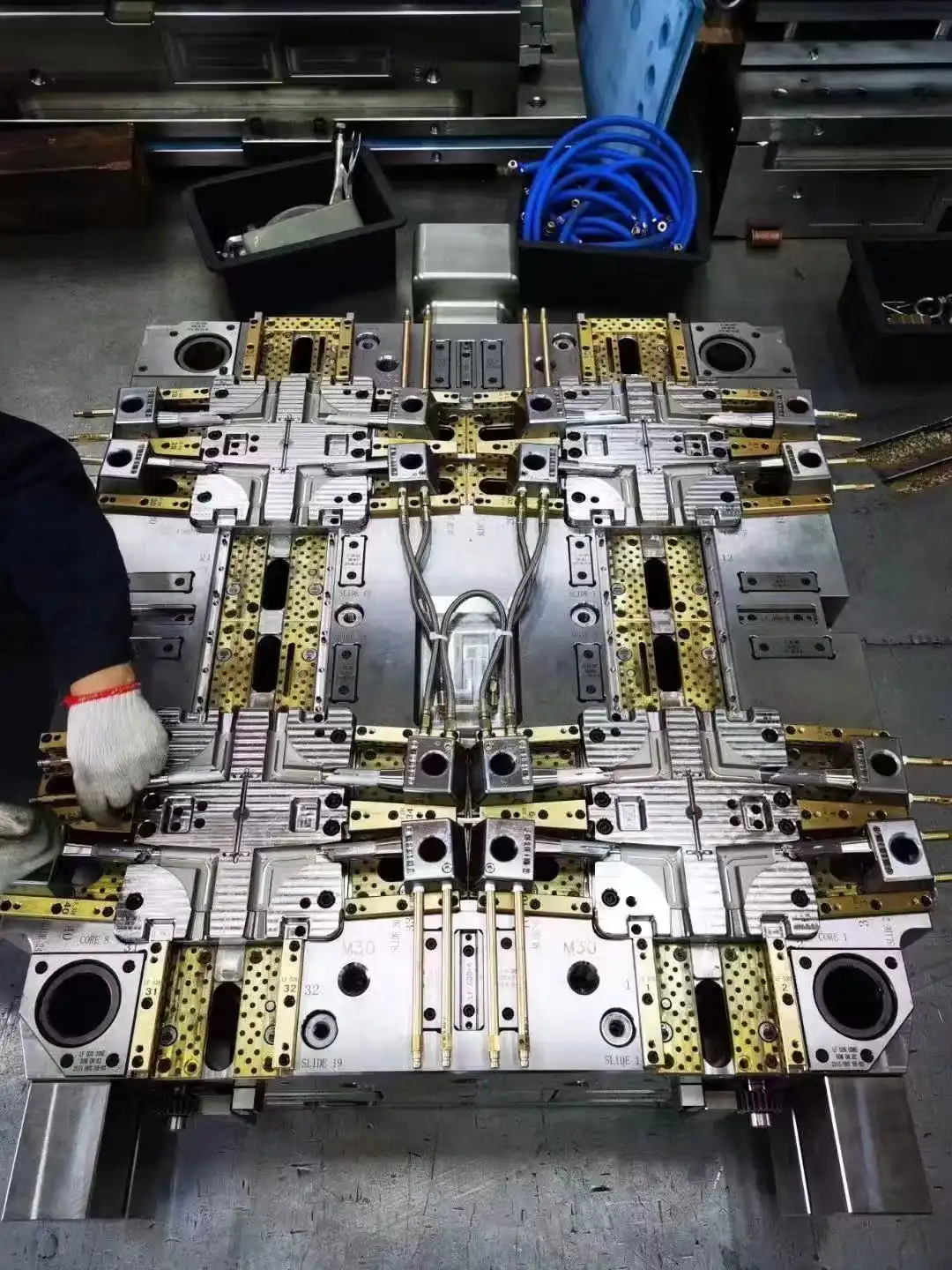

Alwin Asia Limited, registered in Hong Kong, and its subsidiary Dongguan Yongsheng Hardware Plastic Product Co., Ltd., have been at the forefront of mold manufacturing for over 20 years. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, our ISO9001:20015 certified factory specializes in plastic molds, die casting molds, and plastic products. With a commitment to high quality, cost-effectiveness, and timely delivery, we offer comprehensive services from design and development to production and secondary processing. Our convenient location near Shenzhen Airport makes it easy for clients to visit and collaborate. For more information or to discuss your mold manufacturing needs, please contact us at sales-c@alwinasia.com.

FAQ

Q: What is the most effective surface treatment for improving mold durability?

A: The most effective treatment depends on the specific application, but PVD and CVD coatings are widely considered among the best for enhancing mold durability.

Q: How does nitriding improve mold manufacturing durability?

A: Nitriding creates a hard, wear-resistant surface layer by diffusing nitrogen into the mold material, improving hardness and corrosion resistance without affecting core properties.

Q: Can laser texturing improve the efficiency of the molding process?

A: Yes, laser texturing can enhance release properties, reduce friction, and improve part quality, leading to reduced cycle times and increased efficiency.

Q: What are the benefits of electropolishing in mold manufacturing?

A: Electropolishing provides a smooth, bright finish with improved corrosion resistance, easier cleaning, and enhanced overall surface quality.

Q: How do thermal spray coatings compare to PVD and CVD coatings?

A: Thermal spray coatings offer quick application and versatility but may not provide the same level of precision and uniformity as PVD and CVD coatings.

References

1. Smith, J. (2020). Advanced Surface Treatments for Mold Manufacturing. Journal of Materials Engineering and Performance, 29(8), 4875-4890.

2. Johnson, A., & Brown, B. (2019). Comparative Study of PVD and CVD Coatings in Injection Molding. International Journal of Metalcasting, 13(3), 516-529.

3. Lee, C., & Kim, D. (2021). Surface Hardening Techniques for Improved Mold Durability. Surface and Coatings Technology, 405, 126521.

4. Wang, X., et al. (2018). Laser Surface Texturing of Injection Molds: A Review. Journal of Manufacturing Processes, 36, 388-402.

5. Zhang, Y., & Liu, H. (2022). Electropolishing in Mold Manufacturing: Current Status and Future Prospects. Surface Engineering, 38(2), 267-280.

6. Thompson, R. (2017). Thermal Spray Coatings for Mold Protection: Applications and Performance. Journal of Thermal Spray Technology, 26(5), 992-1010.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer