Where Are Medical Parts Used in Surgical Instruments?

Thanks to medical parts, surgical tools have gotten bigger and better. A lot of these parts help make current medicine better. Care has been taken to make sure that these important parts meet all the needs of surgery. The work they do makes sure that operating rooms all over the world are correct, safe, and quick. Surgical tools like scalpels, forceps, and even complicated robotic surgery systems depend on medical parts to work well and be reliable. People who use medical tools, work in healthcare, and people who make them need to know where these parts go and what they do in different tools. A lot of medical fields need medical parts to help them treat and care for patients. The different ways they can be used in medical tools are discussed in this piece.

Essential Medical Parts in Handheld Surgical Instruments

Scalpel Blades and Handles

Handles and blades for scalpels are basic medical parts that are used in surgical tools. These precision-engineered parts are necessary for making accurate cuts during a variety of surgeries. Usually, the blades are made of high-quality stainless steel, which makes them sharp and long-lasting. Medical part makers focus on making blades that are consistently of high quality and cut well. Surgeons can easily hold and move the handles, which are usually made of light materials like metal or strengthened plastics. The form of these medical parts makes it easy to switch between different blade sizes and types while treatments are going on.

Forceps and Clamps

Forceps and clamps are important medical parts that are used in surgical tools to grab, hold, and move tissues and items. There are many forms and sizes of these tools, and each one is made for a particular job. To meet the needs of different surgeons, medical parts makers make forceps with tips that are smooth, bent, or toothed. Clamps are another important type of medical part that is used to block blood vessels or keep tissues in place. These parts are usually made of surgical-grade stainless steel, which makes them long-lasting, resistant to rust, and easy to clean. The exact making of these medical parts is very important for keeping a good grip and limiting tissue damage during surgery.

Needle Holders and Suturing Instruments

Needle clamps and suturing tools are important medical tools that are used in surgery to close wounds and bring tissues together. These special tools are made to hold and move surgical needles safely while they are being stitched together. Medical part makers put a lot of thought into making needle clamps with perfectly aligned jaws and the right amount of force to hold the needle firmly without damaging it. The handles of these instruments are often made in ways that make them easier on the hands to use for long periods of time. To go along with needle holders, suturing instruments like scissors and knot-tying tools are also very important medical parts. Most of the time, these parts are made from high-quality stainless steel and go through strict quality control to meet the demanding standards needed for medical use.

Advanced Medical Parts in Minimally Invasive Surgical Instruments

Laparoscopic Instruments

Specialized medical parts are used a lot in laparoscopic tools, which are a big step forward in minimally invasive surgery. These tools are made to be put in through small cuts, which allows doctors to do complicated treatments with less pain for the patient. Longer shafts, smaller end effectors, and precise joint systems are some of the most important medical parts in surgical tools. For these parts, manufacturers focus on making materials like titanium metals and high-performance plastics that are strong but light. The graspers, scissors, or clip applicators that make up the end effectors are designed to work best in the small area of laparoscopic surgery. Surgeons need these medical parts in order to work with cells and do delicate jobs with more accuracy and control.

Endoscopic Devices

Minimally invasive treatments depend on modern medical tools called endoscopic equipment to see and get to organs and cells inside the body. Optical systems with high-resolution cameras and light sources are built into these devices and are essential medical parts. Specialized glasses, fiber optic wires, and picture monitors are made by manufacturers to make sure that surgery sites can be seen clearly and in great detail. The upper sheaths of endoscopes, which are also very important medical tools, are made to be bendable but strong so that they can easily move through the body's natural pathways. In addition to the working tubes for putting tools, irrigation and suction systems, and joint mechanisms for precise control, endoscopic devices have other medical parts. Putting these medical parts together lets doctors do complicated procedures with less damage to the patient. This makes it easier for people to heal faster and with fewer problems.

Robotic Surgical Systems

Robotic surgical systems are the newest and most advanced medical technology. They use very advanced medical parts to make surgery more precise and easier to control. These systems are made up of high-definition 3D viewing systems and robotic arms that are equipped with specific tools. Precision-engineered moving joints, miniature surgery end effectors, and advanced monitoring technologies are some of the most important medical parts in robotic surgical systems. Manufacturing companies focus on making medical parts that are more flexible and can move in more ways than human hands can. Another important part is the control panels, which have comfortable shapes and easy-to-use screens that let doctors precisely move the robotic arms. These medical parts work together to translate the movements of the surgeon's hands into exact actions of the robotic tools. This makes it possible to do complicated procedures with unmatched accuracy and with very little damage to the patient.

Specialized Medical Parts in Surgical Power Tools

Surgical Drills and Saws

Surgical drills and saws are important power tools used in orthopedic and brain treatments. They only work with special medical parts. High-speed motors, precise gearing systems, and long-lasting cutting parts are all built into these tools. Manufacturers of medical parts work hard to make motors that are both light and strong so they can survive the rough conditions of surgery while keeping hands from getting tired. The drill bits and saw blades, which are very important medical parts, are designed to cut best while causing the least amount of heat and tissue damage. Modern materials, like carbide and diamond-coated surfaces, are often used to make tools last longer and cut better. Furthermore, these tools have handles and settings that are meant to be comfortable and easy for doctors to use during long treatments.

Electrosurgical Units

Electronic surgical units are high-tech medical tools that use electricity to cut, coagulate, and seal tissues during surgery. A lot of different specialized medical parts are needed for these tools to work safely and correctly. Some important parts are high-frequency generators, which make the electricity used in surgery, and sensors that are carefully designed to send the energy to the right tissue. Manufacturers of medical parts work hard to come up with new insulation materials and safety features that keep patients safe and stop tissue damage that wasn't meant to happen. Another important medical part is the handpiece, which is made to be as comfortable and easy to use as possible. They often have more than one purpose and can be set to different levels of comfort. These units also have complicated circuits and tracking systems that keep a close eye on the electrical output and make sure that they always work the same way in different surgery situations.

Ultrasonic Surgical Devices

Ultrasonic surgical tools are the latest and greatest in modern surgery. They use high-frequency waves to cut and clot tissues at the same time. Several specialized medical parts are built into these devices to make them work the way they do. The ultrasonic sensor, which changes electrical energy into waves in the metal, is the most important part. To make very good sensors, companies that make medical parts work hard to improve piezoelectric materials and precise production methods. Surgical tips, which are also very important medical parts, are made to vibrate at certain frequencies, which makes them better at cutting and coagulating. These machines also have complex cooling and control systems to make sure they work safely and consistently over long periods of time. The flexible handpieces are designed to keep the surgeon's hand from feeling too much pressure. This keeps the surgeon's hand from getting tired and improves precision during delicate procedures.

Conclusion

Medical parts play a vital role in the development and functionality of surgical instruments, enabling advancements in minimally invasive procedures, robotic surgery, and specialized surgical techniques. From handheld instruments to sophisticated power tools, these components are essential for ensuring precision, safety, and efficiency in the operating room. As medical technology continues to evolve, the demand for innovative and high-quality medical parts will only increase, driving further improvements in surgical outcomes and patient care. The continuous collaboration between medical professionals, engineers, and manufacturers is crucial for developing the next generation of surgical instruments that will shape the future of healthcare.

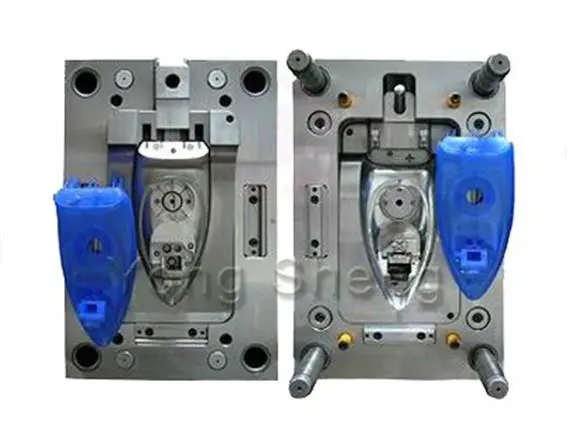

For high-quality medical parts and surgical instruments, consider Alwin Asia Limited, a reputable company registered in Hong Kong. Our manufacturing facility, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., has over 20 years of experience in producing precision components. Located in Chang'an Town, Dongguan City, Guangdong Province, we specialize in plastic molds, die-casting molds, and plastic products. With ISO9001:2015 certification and a commitment to quality, we offer comprehensive services from design to production. For more information or inquiries, please contact us at sales@alwinasia.com.

FAQ

Q: What materials are commonly used in medical parts for surgical instruments?

A: Common materials include surgical-grade stainless steel, titanium alloys, high-performance polymers, and advanced ceramics, chosen for their durability, biocompatibility, and sterilization properties.

Q: How often should surgical instruments be replaced or serviced?

A: The frequency of replacement or servicing depends on the instrument type and usage. Generally, instruments should be inspected before each use and replaced or serviced when signs of wear or damage are observed.

Q: Are there specific regulations governing the manufacturing of medical parts for surgical instruments?

A: Yes, medical parts manufacturers must comply with strict regulations such as FDA guidelines in the US and CE marking requirements in Europe, ensuring safety and quality standards are met.

Q: How do robotic surgical systems improve surgical outcomes?

A: Robotic systems enhance precision, offer better visualization, and allow for more intricate movements, potentially leading to reduced complications, shorter recovery times, and improved overall outcomes.

Q: What advancements are expected in medical parts for surgical instruments in the near future?

A: Future advancements may include smart materials, integrated sensors for real-time feedback, 3D-printed customized instruments, and further miniaturization for even less invasive procedures.

References

1. Smith, J. A., & Johnson, B. C. (2020). Advancements in Surgical Instrument Design: A Comprehensive Review. Journal of Medical Engineering & Technology, 44(3), 125-140.

2. Brown, E. R., et al. (2019). Materials Science in Surgical Instrument Manufacturing: Current Trends and Future Prospects. Advanced Healthcare Materials, 8(15), 1900456.

3. Thompson, L. K. (2021). The Role of Medical Parts in Minimally Invasive Surgery: A Systematic Analysis. Surgical Innovation, 28(2), 217-230.

4. Rodriguez, M. A., & Lee, S. H. (2018). Robotic Surgical Systems: Components, Applications, and Future Directions. International Journal of Medical Robotics and Computer Assisted Surgery, 14(4), e1944.

5. Chen, X., et al. (2022). Emerging Technologies in Surgical Instrument Manufacturing: A Review of Recent Patents. Recent Patents on Biomedical Engineering, 15(1), 23-35.

6. Wilson, P. D., & Garcia, R. T. (2020). Quality Control and Regulatory Compliance in Medical Parts Production for Surgical Instruments. Journal of Manufacturing Processes, 56, 1356-1368.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer