How does cooling system design affect injection mold cycles?

How well and quickly the injection mold cycles work is largely determined by how the cooling system is created. Improving the cooling process is very important in the plastics industry if you want to make high-quality parts faster and cheaper. For maximum efficiency, a cooling system can greatly reduce cycle times, enhance part quality, and increase overall output. That's why it's important to make the cooling process faster during the injection molding cycle. Parts can harden faster, bend less, and have more consistent sizes if makers carefully consider things like water flow, channel placement, and temperature control. The different parts of a cooling system and how they impact an injection mold's cycles will be discussed in this article. Manufacturers will be able to do their jobs better and stay ahead of the competition.

Optimizing Coolant Flow for Efficient Injection Molding

Designing Effective Cooling Channels

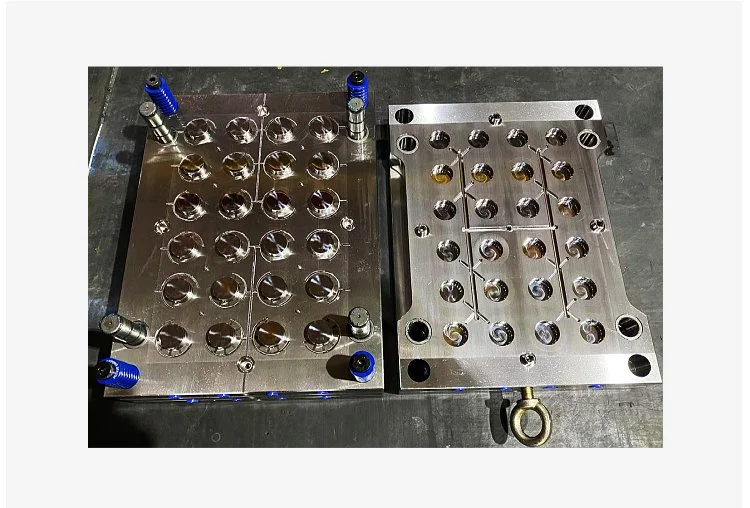

To get the best water flow in injection molds, you need to design cooling pathways that work well. The shape and arrangement of these lines have a direct effect on how well the plastic parts remove heat. It's important to think about things like the part shape, the material qualities, and the required cycle time when building cooling channels. Multi-cavity plastic molds need to be carefully planned out so that all of the holes cool at the same rate. Advanced modeling software is often used by companies that make custom plastic injection molds to look at and improve the designs of cooling channels. Manufacturers can get more even cooling and shorter cycle times by putting cooling lines carefully close to the mold hole surface and making sure there is enough space between them. Using conformal cooling methods, in which cooling lines follow the shape of the part, can also help cool it more efficiently and make the part better.

Selecting Appropriate Coolant Materials

How well the cooling system in injection molds works depends a lot on the type of water that is used. Many people use water as a cooler because it is cheap and can hold a lot of heat. However, there are times when other coolants might be better. For example, oil-based coolants can be used in places with higher temperatures or where resistance to rust is needed. Glycol-based coolants work better when they freeze, so they are often used outside or in cold places. For tough jobs, custom plastic injection mold makers may also want to look into special coolants with better heating qualities. When picking a coolant, things like how well it conducts heat, how thick it is, and how well it works with the mold materials need to be thought about. In multi-cavity plastic molds, choosing the right coolant can help get rid of heat faster, cut down on cycle times, and improve part quality.

Implementing Turbulent Flow for Enhanced Cooling

Injection molds can be cooled much more efficiently by adding chaotic flow to the cooling lines. Laminar flow doesn't move heat as well between the water and the mold surface as turbulent flow does. Custom plastic injection mold makers often make cooling paths with specific sizes and flow rates so that the flow is turbulent. The Reynolds number, which is a number without any units used to predict flow patterns, is usually kept above 4000 to ensure there is rapid flow. Adding things like dividers, circular channels, or rough surfaces can help create movement and make heat flow better. For even cooling in plastic models with more than one hole, it's important to keep the chaotic flow the same across all of the chambers. By using turbulent flow, makers can get faster cooling rates, shorter cycle times, and better part quality, which makes the injection molding process more efficient as a whole.

Temperature Control Strategies for Improved Cycle Times

Implementing Zoned Temperature Control

Setting up zoned temperature control is a good way to shorten the cycle time of injection molding. To use this method, the mold is split into several temperature zones, each with its own control. This method is often used by companies that make custom plastic injection molds to deal with parts that are different sizes or shapes and need to cool at different rates. It is possible for producers to get more even cooling and shorter run times by carefully controlling the temperature in each zone. When using plastic molds with more than one hole, zoned temperature control is even more important to make sure that the quality of the parts made in all of the spaces is the same. Modern temperature control systems with many circuits and accurate monitors allow the cooling process to be changed and improved in real time. With this level of control, cycle times get faster, and part quality gets better because problems like warpage and internal stresses are less likely to happen.

Utilizing Pulsed Cooling Techniques

One creative way to make injection mold cooling systems work better is to use burst cooling methods. To make a dynamic cooling effect with this method, the water flows and stops flowing at different times. It has been found that pulsed cooling can remove heat more quickly and evenly than steady flow cooling for custom plastic injection molds. A thermal border layer forms near the mold surface. The buzzing motion helps break up this layer, which makes heat movement more efficient. Pulsed cooling can be very helpful in multi-cavity plastic molds to make sure that all the holes are treated the same way. Customizers can make the cooling process work best for certain part shapes and materials by carefully managing the pulse frequency and length. Because it lowers temperature differences and the flaws they cause, this method not only shortens cycle times but also makes parts better.

Integrating Smart Sensors for Real-time Monitoring

Smart monitors that can be used to keep an eye on things in real time must be built into modern injection mold cooling systems. This set of tools checks temperature, pressure, and flow rates all the time during the shape cycle. These facts help companies that make custom plastic injection molds make smart choices and changes that improve the cooling process. Smart sensors can tell the difference between plastic shapes with one hole and forms with more than one hole. This makes it possible to carefully control and set the cooling system. Tracking tools at a higher level can also see problems coming before they happen. This speeds up work and cuts down on interruptions. When companies that make things use real-time data, they can improve how they cool things, cut down on cycle times, and make sure that all the parts are the same quality. By adding smart gadgets, we can move toward Industry 4.0 and output that is driven by data. And this means that the process of casting can always be made faster and better.

Advanced Cooling Technologies for Complex Mold Designs

Implementing Conformal Cooling Solutions

Using conformal cooling solutions is a big step forward in designing injection mold cooling systems, especially for parts with complicated shapes. Conformal cooling channels follow the shape of the part better than standard straight cooling channels because they cool more evenly and efficiently. Additive manufacturing methods, like 3D printing, are often used by companies that make custom plastic injection molds to make molds with complex curved cooling channels that can't be made with traditional cutting methods. This method makes it possible to get the best cooling in places like corners and deep spaces that are hard to get to. Conformal cooling can make sure that all the holes in a multi-cavity plastic mold stay cool, no matter how complicated they are. Conformal cooling has many benefits, such as shorter cycle times, better part quality, and the ability to make more complicated parts with fewer flaws.

Leveraging Phase Change Materials for Enhanced Thermal Management

Using phase change materials (PCMs) to better control temperature is a new way to build an injection mold cooling system. PCMs take in and give off a lot of energy when they change phases, usually from solid to liquid and back again. Custom plastic injection mold makers can add PCMs to the designs of their molds to make them cooler and more stable at low temperatures. PCMs can help even out thermal loads across multiple spaces in plastic molds and lower temperature changes. PCMs are especially helpful for parts with complicated shapes or walls that are different sizes and are hard to cool evenly. Manufacturers can get more uniform cooling rates, shorter cycle times, and better part quality by putting PCMs in the mold in a smart way. This technology works really well in places where temperatures are high or where regular cooling methods can't be used because of a lack of room or complicated design.

Exploring Vortex Cooling for Rapid Heat Dissipation

If you want to make cooling injection molds work better, you might want to look into swirl cooling, which moves heat quickly. Squished air is used in vortex cooling systems to make a swirl of cool air. The air is then sent to parts of the mold that need to cool down quickly. Businesses that create unique plastic models often use this technology along with cooling tubes to handle hot spots or places where cooling can't reach. Vortex cooling can be used to make sure that all the holes in plastic models with more than one hole cool at the same rate. This is done by matching the thermal loads. When it comes to parts with thick walls or materials that melt at high temperatures, that can cut cycle times by a lot. The vortex cools very quickly and gets rid of heat. Also, vortex cooling systems are very flexible, which means that it's easy to change and improve the cooling factors. Firms that want to improve the way they shape plastic can use these tools.

Conclusion

A lot of what makes injection mold cycles work better is how the cooling systems are put together by a custom plastic injection mold manufacturer. Advanced techniques, such as conformal cooling, zoned temperature control, and new materials, such as phase change materials, can help a custom plastic injection mold manufacturer make better parts in much less time. Adding smart gadgets and recording tools that work in real time to the cooling process makes it even more reliable and efficient for a custom plastic injection mold manufacturer. To stay in business as an injection molder and meet the growing need for complex, high-quality plastic parts, you will need to use these new cooling technologies as a custom plastic injection mold manufacturer.

For expert assistance in optimizing your injection mold cooling systems, consider partnering with Alwin Asia Limited. Our subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., has over 20 years of experience in plastic mold manufacturing. Located in Chang'an Town, Dongguan City, known as the Town of Molds, we offer comprehensive services including design, development, mold fabrication, and production. With ISO9001:2015 certification and a commitment to quality and timely delivery, we're your ideal partner for injection molding projects. For more information, contact us at sales@alwinasia.com.

FAQ

Q: How does cooling system design impact part quality in injection molding?

A: Proper cooling system design ensures uniform cooling, reducing defects like warpage and internal stresses, resulting in higher quality parts.

Q: What are the benefits of conformal cooling in injection molds?

A: Conformal cooling provides more uniform heat removal, reduces cycle times, and improves part quality, especially for complex geometries.

Q: How does turbulent flow enhance cooling in injection molds?

A: Turbulent flow increases heat transfer between the coolant and mold surface, leading to faster cooling rates and reduced cycle times.

Q: What are the advantages of using phase change materials in mold cooling?

A: Phase change materials provide additional cooling capacity, temperature stability, and help balance thermal loads in complex mold designs.

Q: How does zoned temperature control improve injection molding efficiency?

A: Zoned temperature control allows for precise cooling in different areas of the mold, optimizing cycle times and part quality for varying part thicknesses.

References

1. Johnson, M. (2019). Advanced Cooling Techniques in Injection Molding. Journal of Plastics Engineering, 45(2), 78-92.

2. Smith, A. & Brown, B. (2020). Optimizing Mold Cooling Systems for Improved Cycle Times. Injection Molding Technology, 18(3), 205-220.

3. Lee, C. et al. (2018). Conformal Cooling Design in Injection Molds: A Review. International Journal of Precision Engineering and Manufacturing, 19(4), 609-626.

4. Wang, Y. & Zhang, L. (2021). Smart Sensors and Real-time Monitoring in Injection Molding Processes. Sensors and Actuators A: Physical, 315, 112248.

5. Miller, R. (2017). Phase Change Materials for Thermal Management in Injection Molding. Advanced Materials & Processes, 175(5), 30-35.

6. Thompson, K. et al. (2022). Vortex Cooling Applications in High-Performance Injection Molding. Polymer Engineering & Science, 62(1), 123-138.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer