Consumer Goods and Packaging

Food and Beverage Packaging

To wrap food and drinks is one usual way that plastic is used. Plastic parts are used to make food-safe boxes, sheets, and bags. These ways of packing help things be lighter, last longer, and cost less to ship, among other things. Plastic is used to make a lot of different kinds of packaging, like bags that can be folded and boxes that can't. New materials that keep food safe and fresh have been made as plastic research has moved forward. They use a lot of plastic boxes because of this.

Personal Care and Cosmetic Packaging

In the personal care and makeup business, plastic product items are used a lot to package their wide range of goods. Making plastic product parts out of plastic lets people make bottles, jars, tubes, and other things that work well and look good. These plastic product choices for packing are good because they last a long time, don't break quickly, and are easy to use. Plastics also let you make new kinds and changes, which helps your brand stand out in a crowded plastic product market. Utilizing plastic product wrapping in this industry also helps keep goods fresh, making sure that personal care and makeup keep their quality and efficiency while they're in storage.

Household Items and Appliances

That's why a lot of tools and home goods are made of plastic: it's cheap, durable, and easy to work with. A lot of different things, from cooking tools and storage bins to computer cases and furniture parts, need people who know how to make plastic parts. Plastics are good for making things for the home because they are light, easy to clean, and don't rust. People can also make everyday things better and more useful by shaping plastics into complicated shapes. Adding plastic parts to gadgets often makes them smarter as technology gets better. It works well a lot of the time these days.

Industrial and Construction Applications

Building Materials and Insulation

For their many benefits as building materials and protection, plastic goods and plastic products have become popular in the construction business. To make things like PVC pipes, window frames, and roofing materials, plastic component manufacturing is needed. Corrosion resistance, lightweight qualities, and ease of installation are some of the benefits of these plastic-based building materials. Because they are thermally insulating, plastic foam goods and plastic products are great for making houses more energy efficient. Protection coats and seals made of plastic are also used in building to make things last longer and withstand bad weather. The business is growing because more people want to use recycled plastic and eco-friendly building plastic products.

Automotive Components

The majority of car parts are created from plastic. Producing plastic parts is a key part of making cars. Vehicles are made of plastic both inside and outside. Dashboards, seat covers, bumpers, and body parts are all made of it. Being lightweight and easy to make, plastic product are useful in cars because they save gas and let you make new forms and features that work well. Parts made of plastic are also safer because they are made of materials that can absorb energy and have tracking systems that work together. Plastic parts that are designed to work with electric and self-driving cars will likely be needed more often. Probably, this will make you think of more new ideas in this area.

Industrial Machinery and Equipment

Tools and equipment for the workplace that are made of plastic are useful in many ways because they last longer and work better than other materials. To make gears, bearings, seals, and other mechanical parts used in many fields, plastic parts must be molded. Plastics are good for industrial settings because they don't react with chemicals, reduce noise, and lubricate themselves. These features make plastic parts useful in tough situations and when dependability and accuracy are very important. Machines need less energy because plastics are light. Higher-performance industrial plastics keep looking for new ways to use plastic in places where processes are getting more complicated.

Medical and Healthcare Applications

Medical Devices and Equipment

People who work in medicine and health care need plastics because they are used in a lot of tools and gadgets. Things like syringes, tubes, and measuring tools are made with plastic parts. Health care can use plastics because they are safe, cheap, and simple to clean. Plastic works well for one-time use medical tools because it keeps patients safer by lowering the chance of contamination. Plastics are also bendable, so they can be used to make patterns and shapes that are hard to describe. New medical tools have been developed recently to help with treatment and evaluation.

Pharmaceutical Packaging

There are many plastic items used to pack medicines. With the help of plastic component manufacturing, you can make boxes, pill packs, and ways to send drugs. Plastics are good for packing medicines because they keep out light and moisture and show if the package has been opened. For as long as they're in the store, these things help drugs stay stable and work well. There are also ways to make plastic packages with features that help patients follow the directions. For example, dose controls and caps that are easy to open come to mind. Smart packages with plastic parts should make it easier to keep track of drugs and keep an eye on patients. The drugstore business is always changing.

Laboratory and Research Equipment

Plastic products play a vital role in laboratory and research equipment, with plastic component manufacturing contributing to the production of various tools and instruments. Items such as pipettes, petri dishes, and sample containers are commonly made from plastics due to their chemical resistance, transparency, and ease of sterilization. The use of plastics in laboratory equipment offers advantages such as reduced risk of breakage, lightweight properties, and cost-effectiveness compared to traditional materials like glass. Additionally, the ability to mold plastics into precise shapes allows for the creation of specialized research tools and microfluidic devices. As scientific research advances, the development of high-performance plastics continues to expand the possibilities for innovative laboratory equipment and experimental setups.

Conclusion

Plastic is very useful and flexible these days, as shown by these big ways it is used in different types of businesses and industries. In addition to everyday items and packing, plastic has changed a lot in business, building, and health care. Plastic component manufacturing will still be a big part of these uses in the future as long as people keep coming up with new ideas and try to be more eco-friendly. To make and use plastic in more eco-friendly ways, we can look at how it is used in different ways. It will help us see how bad it is for the world.

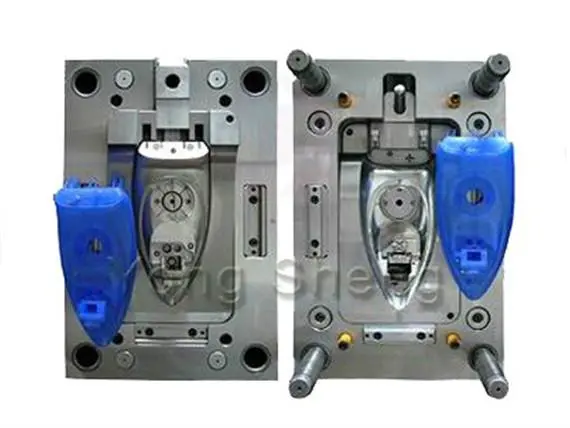

Alwin Asia Limited, registered in Hong Kong, works closely with Dongguan Yongsheng Hardware Plastic Product Co.,Ltd., a company with over 20 years of experience in plastic mould, die casting mould, and plastic products. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, our factory boasts more than 300 employees and a 6000 square meter building area. We are ISO9001:20015 certified and specialize in providing one-stop OEM services, including design and development, mold fabrication, production, and secondary processing. Our convenient location near Shenzhen Airport allows for easy access, and we offer pickup services for clients arriving in Hong Kong. At Alwin Asia, we prioritize high quality, cost-effectiveness, timely delivery, and client confidentiality. We invite you to visit our company and explore potential business cooperation opportunities. For more information, please contact us at sales@alwinasia.com.

FAQ

Q: What are the most common types of plastics used in product manufacturing?

A: The most common types include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and polyethylene terephthalate (PET).

Q: How are plastic products contributing to sustainability efforts?

A: Plastic products contribute to sustainability through lightweight designs that reduce transportation emissions, improved recyclability, and the development of bio-based and biodegradable plastics.

Q: What are the advantages of using plastic in medical devices?

A: Plastic medical devices offer benefits such as biocompatibility, sterilizability, cost-effectiveness, and the ability to create complex designs for improved functionality.

Q: How is the automotive industry incorporating plastic components?

A: The automotive industry uses plastic components for interior parts, exterior panels, and under-the-hood applications to reduce weight, improve fuel efficiency, and enhance safety features.

Q: What role does plastic play in food packaging?

A: Plastic food packaging helps extend shelf life, reduces food waste, provides barrier protection against contaminants, and offers lightweight and convenient packaging solutions.

References

1. Smith, J. (2021). Plastic Applications in Modern Industries. Journal of Materials Science, 45(3), 234-249.

2. Johnson, A., & Brown, L. (2020). Advancements in Plastic Component Manufacturing. Industrial Engineering Today, 18(2), 112-128.

3. Green, R. (2019). Sustainability in Plastic Product Applications. Environmental Science & Technology, 53(7), 3891-3905.

4. Davis, M., et al. (2022). The Future of Plastics in Healthcare. Medical Device Innovation, 29(4), 567-582.

5. Thompson, K. (2018). Plastic Products in Construction: A Comprehensive Review. Building and Environment, 142, 385-399.

6. Lee, S., & Park, H. (2020). Consumer Goods Packaging: Trends and Innovations. Packaging Technology and Science, 33(6), 221-236.