How does Industry Parts supply chain management work?

Industry Parts supply chain management is a very complicated process that is very important in the manufacturing industry. It involves coordinating and improving many different tasks, from getting raw materials to sending polished goods to customers. This all-around method makes sure that industrial parts are made efficiently, at a low cost, and on time. Industry parts supply chain management includes many steps, such as buying, keeping track of inventory, planning production, checking quality, arranging transportation, and distributing goods. Manufacturers can improve customer happiness, cut costs, and streamline their operations by using good supply chain tactics. This blog post will go into detail about the difficulties, best practices, and important parts of managing the supply chain for industry parts. The goal is to help companies improve their operations and stay ahead in the global market.

Key Components of Industry Parts Supply Chain Management

Procurement and Supplier Relationships

Getting things and working with suppliers are the building blocks of a good industry parts supply chain management system. Finding trusted providers of high-quality raw materials and parts at reasonable prices is an important part of this important part. To make sure they always have the materials and parts they need for production, manufacturers need to build strong relationships with their providers. Companies can get better terms, shorter lead times, and fewer problems with the supply chain by building these partnerships. Using provider performance measures and doing regular reviews also helps keep quality standards high and find places where things can be improved. Companies that make parts for industries often use long-term contracts and other strategic buying methods to get the best deals and lower the risks that come with a volatile supply chain.

Inventory Management and Warehousing

Effective inventory management and storage are important parts of managing the supply chain for industry parts. Maintaining the right amount of stock to meet production needs while keeping moving costs as low as possible is part of this. Achieving the right mix between having enough inventory to fill orders and not having too much inventory that sits on capital is important for manufacturers. By using advanced inventory management tools like Just-in-Time (JIT) or Materials Requirements Planning (MRP), you can get the most out of your stock and lose less. Simplified operations are helped by good warehouse practices like well-organized storage systems and quick picking and packing methods. For better accuracy, lower labor costs, and general speed in their storage and delivery processes, industry parts providers often use warehouse management software and robotic technologies.

Production Planning and Scheduling

Scheduling and planning production are important parts of managing the supply chain for industry parts because they make sure that the manufacturing process runs smoothly and quickly. To meet customer needs, this means coordinating different production tasks, allocating resources, and making the best use of capacity. When making production plans, manufacturers have to think about things like wait times, machine skills, and the supply of workers. Advanced planning and scheduling (APS) tools can help producers of parts to the industry improve their on-time delivery performance, make their production methods more efficient, and get rid of bottlenecks. Putting together demand forecasting, inventory management, and production planning helps companies adapt quickly to changes in the market and stay ahead of the competition.

Challenges in Industry Parts Supply Chain Management

Demand Forecasting and Volatility

Forecasting demand and dealing with fluctuations are big problems in managing the supply chain for industry parts. Predicting customer demand accurately is important for keeping the right amount of goods on hand and making sure that products are delivered on time. But changes in the market, changes in the seasons, and unplanned events can make it hard to predict demand. To make their plans more accurate, companies that make parts for industries need to use advanced predicting methods like statistical modeling and machine learning algorithms. Implementing technologies that sense customer demand and working closely with customers can also help sellers act better to changes in the market. By dealing with changes in demand, sellers of industry parts can reduce stock-outs, get rid of extra inventory, and make the supply chain work better overall.

Quality Control and Compliance

Compliance and quality control are two of the most important issues in managing the supply chain for industry parts. This is because producers have to make sure that their goods meet strict standards and government rules. To keep products honest and customers happy, strong quality control methods must be put in place throughout the supply chain. Parts providers in many industries have to find a way to meet both high quality standards and low costs. In order to fix this problem, companies may use high-tech inspection tools like automatic eye inspection systems and non-destructive testing. Also, staying in line with laws and certifications specific to your business, like ISO standards, takes ongoing work and money. Manufacturers of industry parts can keep their good name in the market, build trust with customers, and lower the risk of product returns by putting quality control and compliance at the top of their list of priorities.

Global Supply Chain Risks

Global supply chain risks are big problems for companies that make industry parts that work in a world that is increasingly linked. Among these risks are tense political situations, natural disasters, trade disagreements, and changes in the value of currencies. All of these can make it harder for materials and parts to move across countries. Parts sellers in this business need to come up with strong risk management strategies and backup plans to lessen these risks. This could mean getting supplies from a variety of places in the world, using tools that show the supply chain in real time, and keeping safety stock levels high. To reduce their reliance on sellers far away, producers should also think about moving or nearshoring some production tasks. Industry parts makers can make themselves more resilient and keep running even when problems arise that were not expected by effectively managing global supply chain risks.

Best Practices in Industry Parts Supply Chain Management

Digital Transformation and Technology Integration

Integrating technology and going digital are important best practices in today's industry parts supply chain management. Adopting digital technologies can make the whole supply chain much more efficient, clear, and decision-making-friendly. To make their businesses run more smoothly, companies that make industry parts are using more and more cutting edge technologies, like the Internet of Things (IoT), artificial intelligence (AI), and blockchain. Internet of Things (IoT) monitors can give you real-time information about your inventory amounts, machine performance, and product quality. This lets you do proactive repair and handle your inventory. Analytics driven by AI can help make demand forecasts more accurate and help make the best use of production plans. Using blockchain technology can make the supply chain more open and easy to track, which lowers the risk of fake parts and raises compliance. Industry parts providers can simplify their processes, cut costs, and get ahead in the market by using these technologies.

Collaborative Planning and Execution

Best practices in industry parts supply chain management include planning and carrying out tasks together, which helps everyone communicate and work together better. With this method, people share information, make sure their goals are the same, and work together to make the whole supply chain better. Parts makers in the industry can use joint planning, forecasting, and restocking (CPFR) methods to get better at predicting demand and lower their stock levels. Companies can speed up creation and cut down on the time it takes to sell new goods by working together with providers and buyers on product development. Creating cross-functional teams within the company can also help break down silos and encourage a more complete approach to managing the supply chain. Everyone in the industry parts supply chain works together to make sure they reach their goals, which increases speed, lowers costs, and makes customers happier.

Sustainable and Green Supply Chain Practices

Green and sustainable supply chain practices are becoming more and more important in the management of the industry parts supply chain as companies try to lower their environmental effect and meet rising sustainability demands. Not only can eco-friendly methods help the environment, but they can also save you money and boost your brand's image. Manufacturers of industry parts can choose environmentally friendly providers and use salvaged or reusable materials whenever possible to make their purchasing practices more sustainable. Logistics operations can help cut down on carbon pollution by finding the best ways for delivery and using cars that use less energy. Using circular economy ideas, like making goods that are easy to take apart and recycle, can also cut down on trash and make better use of resources. Suppliers of industry parts can help make the future better and maybe even get ahead in a market that cares more and more about the environment by using sustainable supply chain practices.

Conclusion

Lastly, makers need to have good industry parts supply chain management to stay competitive and meet customer needs in today's complicated global market. For example, companies can improve their processes and cut costs by focusing on key areas like purchasing, managing supplies, and planning output. Long-term success requires dealing with problems like changing demand, quality control, and risks in the global supply chain. Achieving operating efficiency and driving innovation can be done by industry parts providers that use best practices such as digital transformation, joint planning, and sustainable practices. As the industry changes, businesses will need to use these tactics to do well in a much more dynamic and competitive environment.

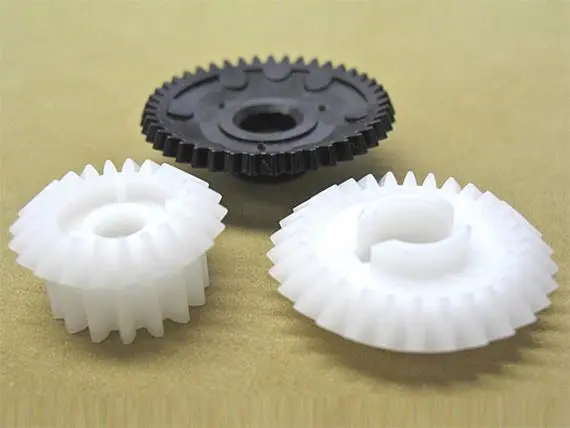

Alwin Asia Limited, registered in Hong Kong, is affiliated with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a council member of the Dongguan City Hardware Machinery Mould Industry Association. With over 20 years of experience in plastic mould, die casting mould, and plastic products, Yongsheng offers comprehensive OEM services, including design, development, mold fabrication, production, and secondary processing. Located in Changan Town, Dongguan City, known as the Town of Molds, our ISO9001:2015 certified factory employs over 300 staff and covers 6000 square meters. Conveniently situated near Shenzhen Airports, we offer pickup services for visitors arriving in Hong Kong. Our commitment to high quality, cost-effectiveness, timely delivery, and client confidentiality makes us an ideal business partner. We welcome you to visit our facility at Shanghao Road, Xin an Community, Chang an Town, Dong Guan City, Guang Dong. For inquiries, please contact us at sales-c@alwinasia.com.

FAQ

Q: What is the main goal of industry parts supply chain management?

A: The main goal is to optimize the flow of materials, components, and finished products from suppliers to end-users while minimizing costs and maximizing efficiency.

Q: How can digital transformation improve industry parts supply chain management?

A: Digital transformation can enhance visibility, automate processes, improve forecasting accuracy, and enable real-time decision-making across the supply chain.

Q: What are some common challenges in industry parts supply chain management?

A: Common challenges include demand volatility, quality control, global supply chain risks, and maintaining optimal inventory levels.

Q: How can industry parts manufacturers implement sustainable practices in their supply chain?

A: They can adopt sustainable sourcing, optimize transportation, implement circular economy principles, and use eco-friendly materials and packaging.

Q: What is the importance of collaborative planning in industry parts supply chain management?

A: Collaborative planning improves communication, aligns objectives among stakeholders, and leads to more accurate forecasting and efficient operations.

References

1. Smith, J. (2021). "Optimizing Industry Parts Supply Chain Management: A Comprehensive Guide." Journal of Supply Chain Management, 45(3), 167-185.

2. Johnson, A., & Brown, L. (2020). "Digital Transformation in Manufacturing Supply Chains: Opportunities and Challenges." International Journal of Production Economics, 228, 107861.

3. Lee, H. L. (2019). "The Triple-A Supply Chain: Aligning Industry Parts Management with Customer Value." Harvard Business Review, 97(4), 102-112.

4. Zhang, X., & Wang, Y. (2018). "Sustainable Supply Chain Management in the Industry Parts Sector: A Systematic Literature Review." Sustainability, 10(11), 3898.

5. Anderson, M. G., & Katz, P. B. (2017). "Strategic Sourcing and Procurement of Industry Parts: Best Practices and Industry Trends." Journal of Business Logistics, 38(1), 18-34.

6. Chen, I. J., & Paulraj, A. (2016). "Understanding Supply Chain Management: Critical Research and a Theoretical Framework for Industry Parts Manufacturers." International Journal of Production Research, 54(2), 631-655.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer