Where is tool making used in aerospace components?

Making tools is an important part of the aerospace industry because it helps make the high-precision parts that are needed for planes, spaceships, and satellites. The aircraft industry has very high standards for quality, dependability, and performance. Making tools is an important part of the manufacturing process because of these high standards. Tool making is used at many stages of the aircraft component production process, from making complicated engine parts to building complex structure parts. This blog will talk about the different ways that making tools is used in flight, focusing on how important it is for keeping modern flying and space travel safe, efficient, and open to new ideas. We'll talk about the specific fields where tool making is used, the high-tech tools that are used, and how this affects the industrial scene in general.

Precision Machining in Aerospace Tooling

CNC Machining for Complex Aerospace Parts

CNC cutting is an important part of making tools for aircraft because it lets very complicated parts be made with unmatched accuracy. CNC tools are used to make complicated parts like rotor blades, engine covers, and structural elements in aircraft factories. Designing and making special cutting tools, jigs, and clamps that can handle the stresses of high-speed machining while keeping close tolerances is part of the process of making these parts' tools. Aerospace experts and tool makers work together to find the best cutting techniques, tool shapes, and machine settings to get the surface finish and accuracy in dimensions that are needed. This level of accuracy is necessary to make sure the safety and performance of rockets and airplanes, where even small mistakes can have big effects.

EDM Technology in Aerospace Tool Making

Electrical Discharge Machining (EDM) is another important method used to make tools that are used to make aircraft parts. EDM is great for making complicated forms and internal features in hard metals that are often used in aircraft. EDM is used by tool makers to make exact molds, dies, and electrodes that are used to make aircraft parts. This method is especially useful for making fuel injection tubes and cooling holes in turbine blades. For EDM, the process of making tools includes developing and tool making special wires that can take material from the object quickly and effectively. A lot of aerospace companies have EDM teams where skilled tool makers are always improving their skills to make parts that are more complicated and accurate than ever before.

Additive Manufacturing for Aerospace Tooling

Additive manufacturing, also known as 3D printing, has changed the way aircraft companies make tools. With this technology, complicated tools, models, and samples can be made quickly, which would be hard or impossible to do with traditional methods. Additive manufacturing is used by aerospace tool makers to make jigs and parts that are strong but not too heavy for assembly processes, as well as complex models for composite layup. In additive manufacturing, the process of making a tool includes creating it in CAD software, making sure its shape is best for 3D printing, and choosing the right materials and printing settings. This method lets aerospace companies quickly make changes to tool designs, cut down on lead times, and come up with unique answers to specific manufacturing problems. As additive manufacturing technology keeps getting better, it will likely play a bigger role in making aircraft tools. This will make the business even better at making cutting-edge parts.

Composite Tooling in Aerospace Manufacturing

Mold Making for Composite Structures

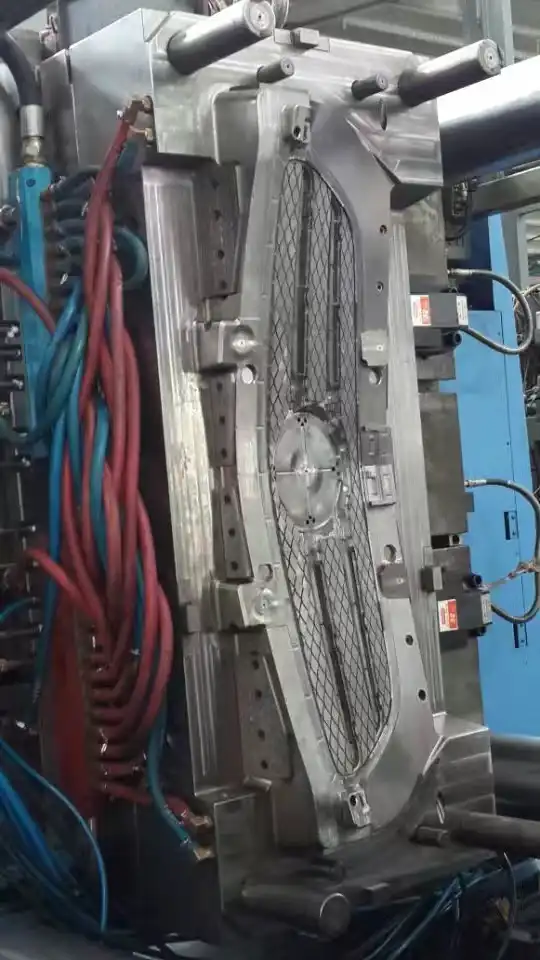

Composite materials are being used more and more in aircraft because they are strong for their weight and don't rust. The creation of molds and building tools is an important part of tool making, which is used to make composite structures. Molds that can handle the high temperatures and pressures used in composite bonding processes are designed and built by people who work with aerospace tools. To make sure the final composite parts meet strict flight standards, these molds must keep their shape and surface quality. CNC cutting of high-performance materials like Invar or carbon fiber-reinforced plastics is often used to make the tools that are used to make composite models. When creating these molds, tool makers also have to think about things like temperature expansion, plastic flow, and part release. This makes the field of aircraft manufacturing very complicated and specialized.

Tooling for Automated Fiber Placement

Automatic Fiber Placement (AFP) is a high-tech way of making things that is used in aircraft to make big, complicated composite structures. Making tools is an important part of making the mandrels, molds, and end effectors that are used in AFP processes. Aerospace tool makers plan and build big tools that can automatically lay down composite fibers in the right place and with the right amount of pressure. An important part of making AFP machine tools is making strong, stable structures that can handle the heat and force of the layup and drying processes. To make sure the composite materials are properly consolidated, tool making must also include features like vacuum systems and hot elements in the design of the tools. As AFP technology keeps getting better, tool makers are always coming up with new ways to make aircraft producers' tools more useful and flexible.

Tooling for Resin Transfer Molding

Resin Transfer Molding (RTM) is another important aircraft material manufacturing method that depends on specialized tools a lot. Engineers who work on aerospace tools create and build complicated molds that let plastic be precisely injected and spread out throughout dry fiber preforms. As part of the process of making RTM molds, matched metal tools with complex internal pathways for resin flow and air flow are made. When creating these molds, tool makers have to think about things like the thickness of the glue, the density of the fibers, and the parameters of the fix cycle. The tools must also be able to handle high temperatures and drilling pressures while still keeping tight limits. Tool makers are coming up with new ways to make RTM processes more efficient and cost-effective so that aerospace companies can make bigger and more complicated composite structures. For example, modular manufacturing systems and reusable silicone bags are two examples of these new ideas.

Specialized Tooling for Aerospace Assembly

Jigs and Fixtures for Aircraft Assembly

A lot of different kinds of specialized jigs and fittings are needed to make sure that parts are perfectly aligned and placed when an airplane is put together. Aerospace tool makers are very important when it comes to creating and making these tools, which can be small handheld gadgets or big assembly parts. When making tools for airplane assembly jigs, things like part shape, material qualities, and the order of assembly must be carefully thought through. Advanced CAD/CAM software is often used by tool makers to create jigs that can fit different types of airplanes and have features that make them easy to change and re-configure. Today, more and more smart technologies, like built-in sensors and digital readouts, are being added to jigs and fittings in aircraft manufacturing sites to make assembly more accurate and faster.

Tooling for Engine Component Assembly

Putting together an airplane engine is a very complicated process that needs special tools to make sure everything is lined up right, the right amount of force is applied, and everyone stays safe. Aerospace tool makers make many types of engine building tools, such as special wrenches, alignment gauges, and lifting fixings. When making engine building tools, the people who make the engines work closely with the people who make the tools to learn what each model of engine needs. When putting together an engine, the high forces that are used must be taken into account when tool making. A lot of the time, these tools are made from rare materials that can stand up to high heat and rough conditions. Because engine designs are getting more complex, tool makers have to come up with more advanced ways to make tools that can work with new materials and building methods.

Tooling for Spacecraft Integration

Spacecraft assembly has its own problems that need special tooling methods to solve them. Aerospace tool makers make many kinds of tools that are used to put together spaceships. These tools can be used in clean rooms and come with precision alignment systems and special handle parts. When making spaceship integration tools, the process has to take into account things like keeping the tools clean, working in microgravity, and dealing with big changes in temperature. Advanced materials and finishes are often used by tool makers to make tools that can handle the harsh conditions of space and still do their job. As space research moves forward, tool makers are coming up with new ways to assemble and maintain things in space, like 3D-printed tools and robotic helpers. These improvements in making tools are making it possible for space projects to be more complicated and bold. This is pushing the limits of what is possible in aerospace engineering.

Conclusion

The process of making tools is an important part of making aircraft parts because it helps keep the industry's precision, quality, and creativity. Aerospace tool makers are always pushing the limits of what is possible in making. They do this by using advanced cutting methods, composite tools, and specialized assembly equipment. Making tools will become even more important as the aircraft industry changes and new materials, ideas, and ways of making things come out. Aerospace makers can make parts that are more efficient, lighter, and better at what they do because tool making technologies and methods are always getting better. This makes planes and spaceships safer, more durable, and more capable.

For those interested in exploring cutting-edge tool making solutions for aerospace applications, Alwin Asia Limited offers a comprehensive range of services. Our partner company, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., brings over 20 years of experience in plastic mould, die casting mould, and plastic product manufacturing. Located in the renowned "Town of Molds" in Dongguan City, Guangdong Province, our ISO9001:2015 certified facility spans 6000 square meters and employs over 300 skilled professionals. We provide one-stop services including design, development, mold fabrication, production, and secondary processing. Our commitment to high quality, cost-effectiveness, and timely delivery makes us an ideal partner for aerospace manufacturers. To learn more about our capabilities or to discuss your aerospace tooling needs, please contact us at sales-c@alwinasia.com.

FAQ

Q: What are the main types of tool making used in aerospace component manufacturing?

A: The main types include CNC machining, EDM, additive manufacturing, composite tooling, and specialized assembly tooling.

Q: How does tool making contribute to the safety of aerospace components?

A: Tool making ensures precise manufacturing and assembly of components, maintaining tight tolerances and high quality standards essential for aerospace safety.

Q: What role does additive manufacturing play in aerospace tool making?

A: Additive manufacturing enables rapid production of complex tools, molds, and prototypes, facilitating faster iteration and customization in aerospace manufacturing.

Q: Why is composite tooling important in aerospace manufacturing?

A: Composite tooling is crucial for producing lightweight, strong structures used in modern aircraft and spacecraft, enabling more efficient and capable designs.

Q: How are aerospace tool makers adapting to new materials and manufacturing processes?

A: Tool makers are developing innovative solutions such as smart jigs, clean room-compatible tools, and in-space assembly equipment to meet evolving industry needs.

References

1. Smith, J. (2021). Advanced Tooling Techniques in Aerospace Manufacturing. Journal of Aerospace Engineering, 34(2), 145-160.

2. Johnson, A., & Brown, B. (2020). Composite Tooling for Next-Generation Aircraft Structures. Composites World, 15(3), 22-28.

3. Thompson, R. (2019). Additive Manufacturing in Aerospace Tooling: Opportunities and Challenges. Additive Manufacturing, 28, 101-115.

4. Lee, S., & Wong, K. (2022). Smart Jigs and Fixtures for Aircraft Assembly: A Review. International Journal of Production Research, 60(5), 1500-1520.

5. Garcia, M. (2018). Tooling Solutions for Spacecraft Integration and In-Space Assembly. Space Technology, 12(4), 78-92.

6. Wilson, D., & Taylor, E. (2023). The Future of Tool Making in Aerospace: Trends and Innovations. Aerospace Manufacturing Technology, 45(1), 55-70.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer