Insert molding technology revolutionizes manufacturing by integrating metal components directly into molded plastic parts. This sophisticated process utilizes specialized inserts molding tools to create robust composite products that combine the strength of metal with the versatility of plastic. The technology addresses critical challenges in modern manufacturing, where single-material components often fail to meet complex performance requirements. By embedding metal components within plastic matrices, manufacturers achieve superior mechanical properties while maintaining cost-effectiveness and design flexibility.

Understanding Inserts Molding Tools and Their Working Principles

What Are Inserts Molding Tools?

Inserts molding instruments speak to specialized gear designed to position and secure metal components inside plastic cavities amid infusion molding forms. These exactness disobedient run from basic manual situating installations to modern computerized frameworks prepared with automated situation components. Each instrument arrangement addresses particular applications and metal embed necessities, serving as the establishment for fruitful fabric integration.

The plan complexity of these instruments depends on components such as embed geometry, generation volume prerequisites, and dimensional resilience determinations. Advanced embed molding frameworks join progressed highlights counting temperature control instruments, vacuum situating frameworks, and real-time checking capabilities to guarantee reliable situation exactness and holding quality.

How Do Inserts Molding Tools Work?

The operational handle starts with exact arrangement of metal embeds into foreordained cavities inside the shape structure. Inserts molding tools keep up correct situating all through the infusion cycle whereas liquid plastic streams around the metal components. As the plastic fabric cements, it shapes mechanical and warm bonds with the implanted metal, making a bound together component with upgraded basic properties.

Temperature administration plays a vital part in this handle. The devices direct warm conditions to optimize plastic stream characteristics whereas anticipating metal embed relocation due to infusion weight varieties. Progressed frameworks join criticism sensors that screen depression filling designs and alter parameters in real-time to keep up holding integrity.

Materials Commonly Used in Inserts Molding Tools

Metal embed determination envelops different materials based on application-specific necessities. Brass components offer great electrical conductivity for electronic applications, whereas stainless steel gives predominant erosion resistance in unforgiving situations. Aluminum embeds convey lightweight arrangements for car applications where weight decrease remains paramount.

Plastic fabric compatibility expands over building polymers counting nylon, polycarbonate, and Look for high-performance applications, as well as general-purpose thermoplastics for customer products. Fabric determination straightforwardly impacts device plan parameters, cycle times, and long-term solidness. Understanding these intelligent empowers ideal fabric blending for particular application requirements.

Advantages of Inserts Molding Tools Compared to Traditional Molding Techniques

Inserts Molding Tools vs. Overmolding Tools

Overmolding innovation covers existing substrates with plastic layers, whereas embed molding implants metal components inside the plastic structure itself. This essential distinction comes about in prevalent mechanical integration and push dispersion capabilities. Embeds molding instruments give upgraded positional exactness and basic solidness compared to overmolding choices, especially in applications requiring exact metal component placement.

The holding components moreover vary essentially between these approaches. Embed molding makes insinuate contact between materials amid the hardening prepare, coming about in more grounded interfacial bonds. This improved integration diminishes the hazard of delamination and makes strides by and large component unwavering quality in requesting applications.

Benefits of Using Inserts Molding Tools for Embedding Metal Components

Manufacturing proficiency advancements speak to one of the most compelling preferences of embed molding innovation. Here are the center benefits that cutting edge producers experience:

- Enhanced basic keenness through optimized push dispersion over metal-plastic interfaces

- Reduced gathering time and labor costs by killing auxiliary holding operations

- Improved dimensional precision and resilience control compared to collected components

- Superior electrical conductivity and warm administration in electronic applications

- Increased plan flexibility for complex geometries and multifunctional components

These points of interest interpret straightforwardly into fetched investment funds and execution enhancements for B2B fabricating operations. The disposal of gathering steps decreases quality control prerequisites and minimizes potential disappointment focuses, coming about in higher by and large item reliability.

Cost and Efficiency Comparison

Economic examination uncovers noteworthy points of interest for embed molding compared to conventional gathering strategies. Generation costs diminish through decreased labor necessities and moved forward cycle effectiveness. Quality advancements result from steady fabricating forms that dispense with changeability related with manual get together operations.

Lead time diminishments ended up especially critical for time-sensitive ventures. Embed molding disposes of different generation stages, permitting producers to provide wrapped up components more quickly. This productivity pick up gives competitive points of interest in markets where speed-to-market decides success.

Design Guidelines and Best Practices for Inserts Molding Tools

Critical Design Considerations for Effective Embedding

Successful inserts molding tools cautious consideration to geometric connections between metal embeds and encompassing plastic fabric. Divider thickness proportions must suit warm development contrasts whereas keeping up auxiliary judgment. Embed situating influences stream designs amid infusion, possibly making weld lines or unfilled ranges without appropriate plan optimization.

Draft points and undermined highlights require uncommon thought in embed molding applications. The nearness of metal components can complicate portion launch, requiring specialized discharge components or altered draft prerequisites. These variables must be tended to amid introductory plan stages to dodge exorbitant adjustments afterward in the improvement process.

Maintenance Tips and Troubleshooting Common Issues

Preventive support conventions expand apparatus life whereas keeping up steady generation quality. Normal cleaning evacuates plastic buildup that can amass around embed situating highlights. Oil of moving components avoids wear and guarantees smooth operation all through generation runs.

Common investigating scenarios incorporate embed uprooting, deficient filling, and holding absconds. These issues regularly stem from dishonorable temperature control, lacking venting, or worn situating instruments. Precise symptomatic strategies offer assistance distinguish root causes and actualize remedial activities quickly.

Industry Applications and Case Studies

Automotive applications illustrate the flexibility of embed molding innovation in requesting situations. Strung embeds inserted in plastic lodgings give secure mounting focuses for basic components whereas decreasing in general gathering weight. Electronic connectors advantage from implanted metal contacts that guarantee solid electrical associations all through item lifecycles.

Consumer merchandise producers utilize embed molding for items requiring both stylish offer and utilitarian execution. Kitchen apparatuses join inserted warming components, whereas control apparatuses coordinated metal fortifications in high-stress zones. These applications exhibit the technology's capacity to upgrade item capabilities whereas keeping up fetched competitiveness.

Procurement Insights: How to Source and Evaluate Inserts Molding Tools?

Key Criteria for Selecting Reliable Inserts Molding Tools Suppliers

Supplier assessment starts with evaluation of specialized capabilities and generation capacity. Producers must illustrate ability in tooling plan, exactness machining, and quality control frameworks. ISO certification and industry-specific capabilities give confirmation of steady quality standards.

Communication capabilities ended up pivotal for worldwide acquirement connections. Providers must give clear specialized documentation, responsive client bolster, and compelling extend administration all through the improvement handle. Social understanding and dialect capability encourage smooth collaboration over distinctive time zones and commerce practices.

Comparing Brands and Cost Structures

Brand comparison includes assessment of mechanical capabilities, benefit offerings, and long-term back commitments. Built up producers regularly give comprehensive preparing programs and specialized help that legitimize higher introductory costs. Rising providers may offer competitive estimating but require cautious assessment of their specialized bolster capabilities.

Total fetched of possession investigation expands past starting apparatus costs to incorporate upkeep necessities, substitution portion accessibility, and generation proficiency variables. This comprehensive approach guarantees ideal esteem over the whole apparatus lifecycle.

Bulk Ordering and Quotation Process for B2B Clients

Efficient acquirement forms consolidate point by point details, volume figures, and conveyance prerequisites. Clear documentation decreases mistaken assumptions and guarantees precise estimating. Bulk requesting transactions can secure favorable terms for long-term supply understandings whereas giving generation plan flexibility.

Quotation forms advantage from standardized ask groups that incorporate all important specialized determinations. This approach empowers exact comparisons between providers and diminishes assessment time for obtainment teams.

Embedding Company Introduction and Product/Service Information

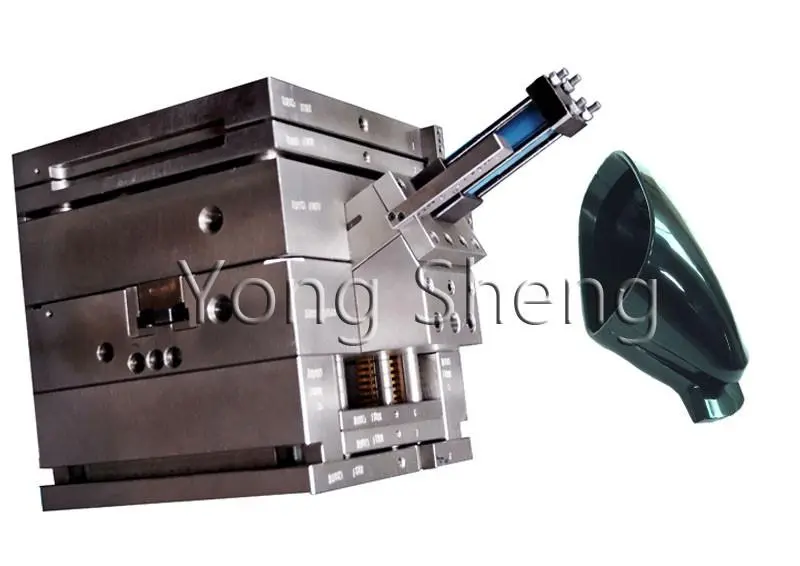

Yongsheng specializes in manufacturing premium inserts molding tools designed for embedding metal components into plastic products. With over 20 years of experience in mold making and plastic production, our company delivers comprehensive solutions from initial design through final production. Our facility in Dongguan, known as the Town of Molds, houses advanced manufacturing equipment and skilled technicians dedicated to precision tooling.

Our one-stop OEM services include design optimization, prototype development, tool fabrication, and volume production. The ISO 9001:2015 certified facility ensures consistent quality standards while our experienced engineering team provides technical support throughout project lifecycles. We understand the unique requirements of international B2B clients and maintain strict confidentiality protocols to protect intellectual property.

Conclusion

Inserts molding tools enable manufacturers to create superior products by combining metal strength with plastic versatility. This technology addresses modern manufacturing challenges while providing cost-effective solutions for diverse applications. Understanding the technical principles, design requirements, and procurement considerations enables informed decision-making for B2B operations. The integration of metal components within plastic matrices represents a proven approach to enhancing product performance while maintaining manufacturing efficiency.

FAQ

Q: What types of metal inserts are compatible with inserts molding tools?

A: Inserts molding tools accommodate various metals including brass, stainless steel, aluminum, and specialized alloys. Material selection depends on application requirements such as electrical conductivity, corrosion resistance, and mechanical strength. Our engineering team provides guidance on optimal material combinations for specific applications.

Q: How long does the lead time typically take for custom inserts molding tool orders?

A: Lead times range from 4 to 12 weeks depending on tool complexity, customization requirements, and order volume. Rush orders may be accommodated based on production schedule availability. We provide detailed project timelines during the quotation process to ensure delivery expectations align with project requirements.

Q: What maintenance practices can prolong the life of inserts molding tools?

A: Regular cleaning, lubrication, and inspection protocols significantly extend tool life. We recommend quarterly maintenance schedules for high-volume applications and provide comprehensive maintenance guidelines with each tool delivery. Our technical support team offers training programs to optimize maintenance effectiveness.

Partner with Yongsheng for Advanced Insert Molding Solutions

Discover how our specialized inserts molding tools can transform your manufacturing capabilities. As a leading manufacturer with decades of experience, Yongsheng delivers precision tooling solutions tailored to your specific requirements. Our comprehensive services include design consultation, rapid prototyping, and volume production support. Experience the reliability of working with an established inserts molding tools supplier committed to your success. Contact us at sales@alwinasia.com to discuss your project requirements and receive a detailed quotation.

References

1. Johnson, R.M. & Chen, L. (2023). "Advanced Insert Molding Technologies in Automotive Manufacturing." International Journal of Polymer Processing, 38(2), 145-162.

2. Martinez, A.P. (2022). "Design Optimization Strategies for Metal-Plastic Composite Components." Manufacturing Engineering Quarterly, 29(4), 78-94.

3. Thompson, K.S. & Williams, D.R. (2023). "Cost Analysis of Insert Molding vs. Traditional Assembly Methods in Electronics Manufacturing." Journal of Manufacturing Economics, 15(3), 234-251.

4. Zhang, H. & Kumar, S. (2022). "Materials Selection Criteria for Insert Molding Applications in Consumer Goods." Polymer Engineering Review, 44(7), 112-129.

5. Brown, M.J. (2023). "Quality Control and Process Optimization in Insert Molding Operations." Industrial Manufacturing Technology, 31(5), 67-85.

6. Lee, C.H. & Anderson, P.T. (2022). "Thermal Management Considerations in Metal-Plastic Insert Molding." Heat Transfer Engineering Applications, 18(9), 203-218.