How is digital transformation affecting tool making?

The tool making industry is experiencing a critical change as advanced innovations proceed to revolutionize fabricating forms. This advanced move is reshaping the way apparatuses are planned, delivered, and utilized over different divisions. From progressed computer-aided plan (CAD) computer program to 3D printing and the Web of Things (IoT), instrument producers are grasping imaginative innovations to improve efficiency, make strides exactness, and meet the advancing requests of advanced businesses. The integration of computerized arrangements is not as it were streamlining generation forms but too empowering the creation of more complex and customized devices. As we dig into the affect of computerized change on instrument making, we'll investigate how these progressions are revolutionizing the industry, moving forward effectiveness, and opening up unused conceivable outcomes for device producers and their clients alike.

The Role of CAD/CAM in Modern Tool Making

Enhancing Design Precision and Efficiency

Computer-Aided Plan (CAD) and Computer-Aided Fabricating (CAM) innovations have ended up crucial in the apparatus making industry. These progressed computer program arrangements empower device creators to make exceedingly precise 3D models, reenact execution, and optimize plans some time recently generation starts. By utilizing CAD/CAM frameworks, producers can altogether diminish plan time, minimize blunders, and make strides in general effectiveness in the device making prepare. The integration of these advances permits for fast prototyping and emphasis, empowering apparatus producers to react rapidly to client input and advertise requests. Additionally, CAD/CAM frameworks encourage consistent collaboration between plan groups and generation floors, guaranteeing that the last item meets the correct details and quality benchmarks required.

Streamlining Production Processes

The execution of CAD/CAM advances in instrument making has revolutionized generation forms, driving to expanded mechanization and diminished manual intercession. These frameworks empower the coordinate exchange of plan information to CNC machines, disposing of the require for manual programming and decreasing the potential for human blunder. As a result, apparatus producers can accomplish higher levels of exactness and consistency in their items. The integration of CAD/CAM with other computerized advances, such as mechanical autonomy and sensors, encourage upgrades the effectiveness of generation lines. This streamlined approach not as it were quickens the fabricating handle but too permits apparatus producers to handle more complex plans and deliver apparatuses with complicated geometries that were already challenging or inconceivable to make utilizing conventional methods.

Facilitating Customization and Rapid Prototyping

Digital change in device making has opened up unused conceivable outcomes for customization and quick prototyping. CAD/CAM innovations empower apparatus producers to rapidly adjust plans to meet particular client necessities without noteworthy extra costs or time speculations. This adaptability permits producers to offer a more extensive extend of items and cater to specialty markets more viably. Besides, the integration of 3D printing advances with CAD/CAM frameworks has revolutionized the prototyping prepare. Apparatus producers can presently deliver useful models in a matter of hours, permitting for speedier plan emphasess and decreased time-to-market for unused items. This quick prototyping capability not as it were improves the tool making prepare but too empowers producers to approve plans and accumulate client criticism more productively, eventually driving to made strides item quality and client satisfaction.

The Impact of IoT and Smart Manufacturing on Tool Making

Real-time Monitoring and Predictive Maintenance

The Web of Things (IoT) has revolutionized the apparatus making industry by empowering real-time checking of generation forms and hardware. Keen sensors and associated gadgets collect tremendous sums of information on device execution, wear, and utilization designs. This riches of data permits apparatus producers to execute prescient support techniques, expecting potential issues some time recently they lead to expensive downtime or quality issues. By leveraging IoT innovations, producers can optimize their support plans, amplify the life expectancy of their gear, and guarantee steady item quality. Moreover, real-time observing empowers device creators to distinguish bottlenecks in their generation forms, driving to persistent advancement and expanded by and large proficiency in their operations.

Data-driven Decision Making and Process Optimization

The integration of IoT and keen fabricating innovations in device making has driven to a critical move towards data-driven choice making. The tremendous sums of information collected from associated gadgets and sensors give important bits of knowledge into each viewpoint of the generation prepare. Instrument creators can analyze this information to distinguish patterns, optimize workflows, and make educated choices to progress productivity and item quality. Progressed analytics and machine learning calculations can be connected to this information to foresee request, optimize stock administration, and indeed propose plan advancements for apparatuses based on real-world utilization information. This data-driven approach empowers device creators to ceaselessly refine their forms, diminish squander, and remain ahead of advertise patterns, eventually driving to expanded competitiveness in the industry.

Enhanced Collaboration and Supply Chain Integration

Digital change in tool making has encouraged improved collaboration and integration over the whole supply chain. IoT and keen fabricating advances empower consistent communication between apparatus producers, providers, and clients. Real-time information sharing permits for superior coordination of generation plans, stock administration, and quality control forms. This expanded perceivability and network all through the supply chain lead to progressed responsiveness to advertise requests and decreased lead times. Moreover, advanced stages and cloud-based arrangements empower device creators to collaborate more viably with their clients, advertising administrations such as inaccessible observing of apparatus execution and prescient upkeep. This closer integration between instrument creators and end-users not as it were progresses client fulfillment but moreover gives important input for ceaseless item change and development in the instrument making industry.

Additive Manufacturing and 3D Printing in Tool Making

Revolutionizing Prototyping and Small-scale Production

Additive fabricating and 3D printing innovations have altogether affected the apparatus making industry, especially in the regions of prototyping and small-scale generation. These advances permit device creators to rapidly deliver complex geometries and complex plans that would be challenging or outlandish to make utilizing conventional fabricating strategies. By leveraging 3D printing, producers can quickly repeat on plans, test numerous models, and approve concepts some time recently committing to full-scale generation. This quickened prototyping prepare not as it were decreases advancement time and costs but too empowers instrument producers to bring inventive items to advertise quicker. Furthermore, 3D printing has opened up modern conceivable outcomes for creating custom or low-volume instruments, permitting producers to cater to specialty markets and particular client necessities more efficiently.

Enabling Complex Geometries and Lightweighting

One of the most critical preferences of added substance fabricating in tool making is the capacity to make complex geometries and inner structures that were already incomprehensible or illogical to deliver. This capability permits apparatus producers to plan and fabricate devices with optimized shapes, progressed usefulness, and diminished weight. Lightweighting through added substance fabricating is especially useful in businesses such as aviation and car, where lessening device weight can lead to noteworthy advancements in execution and vitality productivity. Moreover, the capacity to make complex inner channels and cooling frameworks in instruments improves their execution and life span. By leveraging these progressed fabricating methods, device creators can thrust the boundaries of plan and make inventive arrangements that meet the advancing needs of different industries.

Material Innovations and Hybrid Manufacturing

Additive fabricating has impelled advancements in materials science, driving to the improvement of modern materials particularly outlined for 3D printing applications in device making. These progressed materials offer moved forward mechanical properties, warm resistance, and toughness, extending the extend of applications for 3D-printed apparatuses. In addition, the rise of crossover fabricating forms, which combine added substance and subtractive fabricating strategies, has encourage upgraded the capabilities of apparatus producers. These crossover approaches permit producers to use the benefits of both 3D printing and conventional machining, coming about in apparatuses with prevalent execution characteristics and diminished generation times. As fabric science and fabricating innovations proceed to development, apparatus producers will have get to to an ever-expanding extend of alternatives for making high-performance, customized instruments that meet the particular needs of their clients over different businesses.

Conclusion

Digital transformation is profoundly reshaping the tool making industry, driving innovation, efficiency, and customization. From CAD/CAM technologies and IoT integration to additive manufacturing, these advancements are enabling tool makers to create more complex, precise, and tailored products while streamlining their operations. As the industry continues to evolve, embracing these digital technologies will be crucial for manufacturers to remain competitive and meet the changing demands of their customers. The future of tool making lies in the seamless integration of digital solutions, data-driven decision-making, and innovative manufacturing processes, paving the way for a new era of smart, connected, and highly efficient tool production.

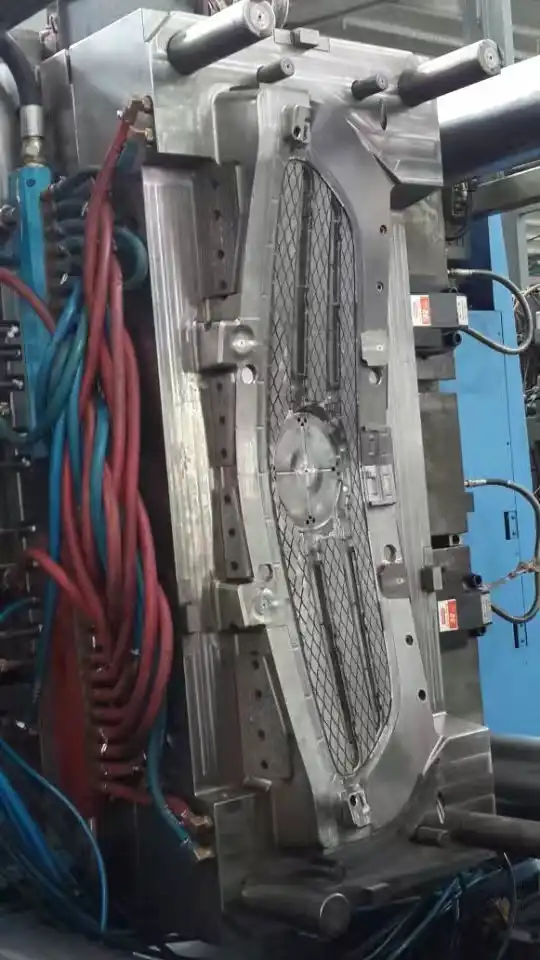

For more information about our tool making services and how we're leveraging digital transformation to meet your needs, please contact Alwin Asia Limited. Our company, registered in Hong Kong, works closely with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a council member of the Dongguan City Hardware Machinery Mould Industry Association with over 20 years of experience in plastic mould, die casting mould, and plastic products. Located in Changan Town, Dongguan City, Guangdong Province, we offer comprehensive OEM manufacturing services, including design, development, mold fabrication, production, and secondary processing. To learn more or to schedule a visit to our facility, please email us at sales-c@alwinasia.com.

FAQ

Q: How does digital transformation improve tool making efficiency?

A: Digital transformation enhances efficiency through CAD/CAM systems, IoT integration, and additive manufacturing, enabling faster design, production, and prototyping processes.

Q: What role does IoT play in modern tool making?

A: IoT enables real-time monitoring, predictive maintenance, and data-driven decision-making, leading to optimized production processes and improved tool performance.

Q: How does 3D printing benefit the tool making industry?

A: 3D printing allows for rapid prototyping, complex geometries, and customization, reducing development time and enabling the creation of innovative tool designs.

Q: What are the advantages of CAD/CAM in tool design?

A: CAD/CAM systems enhance design precision, enable virtual testing, and streamline the transition from design to manufacturing, reducing errors and improving efficiency.

Q: How is digital transformation affecting quality control in tool making?

A: Digital technologies enable more precise measurements, real-time monitoring, and data-driven quality control processes, leading to higher consistency and fewer defects.

References

1. Smith, J. (2022). The Digital Revolution in Tool Making: Trends and Innovations. Journal of Manufacturing Technology, 45(3), 178-192.

2. Johnson, A., & Brown, L. (2021). IoT Applications in Modern Tool Manufacturing. Industrial Internet of Things Quarterly, 12(2), 56-71.

3. Lee, S., et al. (2023). Additive Manufacturing Techniques for Advanced Tool Production. Progress in Additive Manufacturing, 8(1), 23-40.

4. Wilson, R. (2022). CAD/CAM Integration in Tool Design and Fabrication. International Journal of Computer-Integrated Manufacturing, 35(4), 312-328.

5. Garcia, M., & Thompson, K. (2021). Smart Manufacturing and Its Impact on Tool Making Processes. Journal of Intelligent Manufacturing, 32(5), 789-805.

6. Chen, Y. (2023). Digital Transformation Strategies for Small and Medium-sized Tool Manufacturers. Technology in Society, 72, 101834.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer