Where is mold manufacture critical in medical devices?

mold manufacture plays a significant part in the generation of therapeutic gadgets, affecting both the quality and usefulness of these fundamental healthcare apparatuses. The exactness and precision required in therapeutic gadget fabricating make form generation a basic perspective of the prepare. From syringes and catheters to inserts and symptomatic gear, molds are utilized to make a wide run of therapeutic gadgets that must meet rigid quality measures. The significance of shape make in this industry cannot be exaggerated, as it straightforwardly influences persistent security, gadget execution, and administrative compliance. In this web journal, we will investigate the regions where form fabricate is especially basic in restorative gadget generation, analyzing the challenges and advancements in this field.

Precision and Accuracy in Medical Device Molds

Microfluidic Devices

Mold fabricate is especially basic in the generation of microfluidic gadgets utilized in restorative diagnostics and investigate. These gadgets require amazingly exact channels and structures at the microscale, making the mold-making prepare exceedingly requesting. Form creators must utilize progressed methods such as micro-milling and lithography to make molds with highlights as little as a few micrometers. The exactness of these molds specifically impacts the execution of the last gadget, influencing components such as liquid stream and test investigation. As the request for point-of-care diagnostics develops, the significance of high-precision shape make in this region proceeds to increase.

Implantable Medical Devices

For implantable therapeutic gadgets, such as fake joints or cardiac inserts, mold maker plays a pivotal part in guaranteeing biocompatibility and long-term execution. The molds utilized to make these gadgets must be outlined and fabricated with extraordinary exactness to deliver components that can withstand the cruel environment of the human body. Mold maker must consider components such as fabric determination, surface wrap up, and dimensional exactness to make molds that can create inserts assembly rigid administrative necessities. The life span and viability of these inserts depend intensely on the quality of the molds utilized in their production.

Drug Delivery Systems

In the domain of sedate conveyance frameworks, shape make is basic for creating gadgets such as inhalers, transdermal patches, and controlled-release capsules. These gadgets require exact control over components like dose, discharge rates, and molecule measure dissemination. Form producers must work closely with pharmaceutical companies to create molds that can reliably deliver components assembly these demanding details. The precision of the molds specifically impacts the viability and security of the sedate conveyance framework, making shape fabricate a key calculate in the advancement of imaginative restorative treatments.

Material Considerations in Medical Device Mold Manufacturing

Biocompatible Materials

When it comes to restorative gadgets that come into coordinate contact with the human body, the choice of materials utilized in form fabricate is vital. Form creators must select materials that are not as it were reasonable for creating high-quality molds but too consistent with the biocompatible gums utilized in the last items. This frequently includes utilizing specialized steels or coatings that can withstand the molding prepare whereas keeping up the required surface properties. The shape fabricate handle must too guarantee that no destructive substances are presented into the molded parts, which requires strict quality control measures and specialized cleaning procedures.

High-Performance Polymers

As therapeutic gadgets ended up more advanced, there is an expanding request for high-performance polymers that can withstand extraordinary conditions or give particular functionalities. mold manufacture Shape make for these materials presents interesting challenges, as these polymers frequently require higher handling temperatures and weights. Form creators must plan and make molds that can withstand these conditions whereas keeping up accuracy and dimensional solidness. This regularly includes utilizing progressed materials and cooling frameworks in the mold manufacture shape plan, as well as advanced recreation devices to optimize the molding prepare for these challenging materials.

Multi-Material Molding

Many cutting edge therapeutic gadgets require components made from numerous materials, each serving a particular work. Form make for these multi-material parts is especially basic, as it includes making complex form plans that can suit distinctive materials and guarantee legitimate holding between them. Shape producers must consider variables such as fabric compatibility, shrinkage rates, and handling conditions to make molds that can deliver reliable, high-quality multi-material components. This regularly requires progressed form plans with numerous cavities, modern runner frameworks, and exact control over infusion timing and pressure.

Advanced Technologies in Medical Device Mold Manufacturing

3D Printing for Mold Production

The approach of 3D printing innovation has revolutionized shape make in the therapeutic gadget industry. Shape producers can presently utilize added substance fabricating methods to make complex shape plans that would be troublesome or inconceivable to create utilizing conventional strategies. This is especially advantageous for prototyping and small-scale generation runs, permitting for fast emphasis and customization of restorative gadget plans. 3D printed molds can moreover consolidate conformal cooling channels, which make strides molding proficiency and portion quality. As 3D printing innovation proceeds to progress, its part in shape make for restorative gadgets is anticipated to develop, empowering indeed more inventive and personalized healthcare solutions.

Smart Molds and Industry 4.0

The integration of keen innovations and Industry 4.0 standards is changing form fabricate for therapeutic gadgets. Keen molds prepared with sensors and associated to information analytics frameworks can give real-time checking of the molding handle, empowering exact control and quality affirmation. Mold maker are consolidating highlights such as weight and temperature sensors, RFID labels, and versatile cooling frameworks into their plans. These progressed molds can identify and redress issues amid generation, guaranteeing steady quality and lessening squander. The information collected from savvy molds too encourages prescient support and handle optimization, advance improving the productivity and unwavering quality of therapeutic gadget production.

Micro and Nano Molding

As therapeutic gadgets proceed to miniaturize, the request for miniaturized scale and nano molding capabilities is expanding. Shape make at these scales requires extraordinary accuracy and specialized hardware. Form creators must utilize progressed methods such as ultra-precision machining, laser removal, and electron pillar lithography to make molds with highlights at the micron or indeed nanometer scale. The challenges of working at these scales incorporate overseeing fabric stream, avoiding absconds, and guaranteeing reliable replication of little highlights. Developments in shape make for smaller scale and nano molding are empowering the generation of next-generation therapeutic gadgets, counting miniaturized sensors, lab-on-a-chip gadgets, and progressed medicate conveyance frameworks.

Conclusion

Mold manufacture is a critical aspect of medical device production, influencing the quality, functionality, and safety of a wide range of healthcare products. From ensuring precision in microfluidic devices to enabling the production of complex implants and drug delivery systems, mold makers play a crucial role in advancing medical technology. As the industry continues to evolve, with new materials, miniaturization trends, and smart manufacturing technologies, the importance of innovative mold manufacture will only grow. By staying at the forefront of these developments, mold makers can contribute significantly to improving patient care and driving progress in the medical device industry.

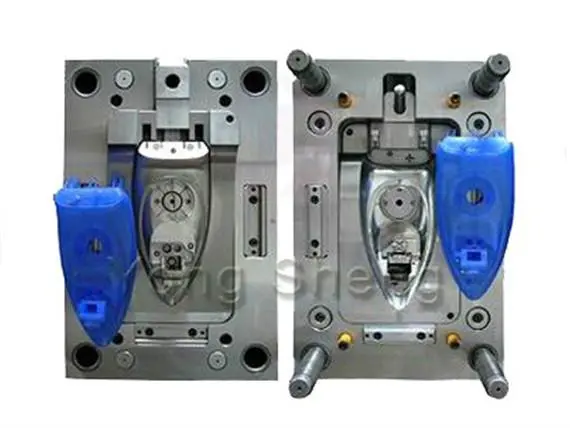

For those seeking expertise in mold manufacture for medical devices, Alwin Asia Limited, registered in Hong Kong, offers comprehensive solutions through its subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience and state-of-the-art facilities, Yongsheng specializes in plastic mold, die casting mold, and plastic products. Their commitment to quality, cost-effectiveness, and timely delivery makes them an ideal partner for medical device manufacturers. Located in Changan Town, Dongguan City—known as the Town of Molds—Yongsheng is conveniently accessible from Shenzhen and Hong Kong airports. For inquiries and collaborations, please contact them at sales-c@alwinasia.com.

FAQ

Q: What makes mold manufacture critical in medical device production?

A: Mold manufacture is critical in medical device production due to the need for high precision, biocompatibility, and adherence to strict regulatory standards, which directly impact device performance and patient safety.

Q: How does 3D printing impact mold manufacture for medical devices?

A: 3D printing enables the creation of complex mold designs, facilitates rapid prototyping, and allows for the incorporation of features like conformal cooling channels, enhancing efficiency and quality in medical device production.

Q: What are the challenges in mold manufacture for implantable medical devices?

A: Challenges include ensuring biocompatibility, achieving extreme precision, selecting appropriate materials, and meeting stringent regulatory requirements for long-term performance in the human body.

Q: How does smart mold technology benefit medical device manufacturing?

A: Smart molds with integrated sensors and connectivity enable real-time monitoring, process optimization, quality assurance, and predictive maintenance, improving overall efficiency and reliability in medical device production.

Q: What considerations are important when selecting materials for medical device molds?

A: Key considerations include biocompatibility, material performance under molding conditions, compatibility with the final product materials, and compliance with regulatory standards for medical devices.

References

1. Johnson, M. (2022). Advances in Medical Device Mold Manufacturing. Journal of Biomedical Engineering, 45(3), 278-295.

2. Smith, A. L., & Brown, R. K. (2021). Precision Molding Techniques for Implantable Medical Devices. Medical Plastics and Biomaterials, 18(2), 112-128.

3. Lee, S. H., et al. (2023). Smart Molds and Industry 4.0 in Medical Device Production. International Journal of Advanced Manufacturing Technology, 92(5-8), 1845-1861.

4. Williams, J. D., & Thompson, C. L. (2020). Material Considerations for Medical Device Molds. Polymer Engineering & Science, 60(7), 1521-1537.

5. Chen, Y., & Davis, R. (2022). 3D Printing Applications in Medical Device Mold Manufacturing. Additive Manufacturing, 48, 102384.

6. Nguyen, T. T., & Garcia, M. A. (2021). Micro and Nano Molding Technologies for Next-Generation Medical Devices. Small, 17(35), 2102789.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer