How to source Industry Parts globally?

In today's globally connected market, companies that want to improve their supply lines and stay ahead of the competition must now get industry parts from all over the world. Finding, analyzing, and working with sellers from different countries to get high-quality industry parts at reasonable prices is what global sourcing is all about. This method not only helps businesses cut costs, but it also gives them access to more cutting-edge tools and specific knowledge. But it can be hard to figure out how to deal with the complicated issues of foreign trade, transportation, and cultural differences. This blog post will talk about good ways to get industry parts for your business from around the world, including important things to think about, the best ways to do things, and mistakes you should try to avoid. Businesses can improve their product quality, cut down on wait times, and eventually make more money by knowing the ins and outs of foreign buying.

Identifying Reliable Global Suppliers

Researching Potential Suppliers

To find trusted sources when buying parts for your business from around the world, you need to do a lot of study. To begin, make a list of possible business partners using online B2B platforms, trade listings, and industry-specific databases. To make connections with makers and wholesalers from different countries, go to foreign trade shows and events. You might want to get in touch with trade groups and houses of commerce in your target areas to get useful information and suggestions. As you cut down your choices, pay close attention to the track records, licenses, and foreign standards that each provider meets. To find out how good and consistent their products are, ask for thorough product specs, examples, and contact information from past customers. Don't forget to think about where the products are coming from; buying them from certain areas may be better for operations or getting specialized knowledge in certain areas of the business.

Evaluating Supplier Capabilities

It's important to carefully check out possible sellers of your industry parts once you've found them. First, you should look at how much they can produce, what technologies they use, and how they enforce quality control. Be sure they can meet your number and quality needs by asking for specific information about their producing sites, tools, and staff. In order to check their claims and see how they work for yourself, you might want to do virtual or on-site surveys. Note how well they can handle requests for change and how ready they are to work with you to make the product better. To reduce the risk of supply chain breakdowns, check to see if they are financially stable and can do business in the long run. If they have exported to your country before, you should also find out how well they know the rules and laws that apply. You can make smart choices and build relationships that help you reach your buying goals if you analyze a supplier's skills in detail.

Building Strong Supplier Relationships

Building good ties with foreign providers is important for getting industry parts. Ensure unity from the start by making your demands, quality standards, and business goals known. Provide fair prices, decent payment terms, and steady order amounts to build a relationship that works for both parties. Learning about your sellers' business and cultural practices will help you communicate and work together more effectively. Give helpful comments and do performance reviews on a regular basis to encourage ongoing growth. You could help your partners improve their skills and help you reach your long-term goals by starting provider development programs. Making your supply chain for industry parts more reliable and flexible by building strong relationships with your suppliers can lead to better quality, new ideas, and greater global market competitiveness.

Navigating International Trade Regulations

Understanding Import/Export Regulations

Before you go looking for parts for your business around the world, make sure you know the rules for bringing things into and out of the country. There are different trade deals, customs procedures, and taxes between the places you want to buy from and sell to. For instance, look into the safety rules, licenses, and papers that your business needs. If trade restrictions, bans, or fines have an effect on your sources, you should be aware of them. You might want to hire customs sellers or trade compliance experts to make sure you're following all the rules. It's important to pay attention to Incoterms when making deals with buyers because they point out who is responsible for what and what the risks are when things are shipped. It can be hard and expensive to break the rules of international trade. Make sure you fully understand and follow these rules to keep your global sourcing projects on track.

Managing Customs and Duties

When buying industry parts for a business from around the world, it's important to keep track of taxes and fees well. To find out what taxes and rules apply to your industry parts, you should first correctly describe them using the Harmonized System (HS) codes. Look into any special trade deals that exist between your country and the places where the industry parts are coming from to find ways to save on duties. Set up an effective way to keep and update industry parts paperwork like packing lists, business bills, and certificates of origin. If you want to delay or lower the tax payments on foreign industrial parts, you might want to use secured stores or free trade zones. Know about anti-dumping and retaliatory taxes because they could affect where you buy industry parts. Come up with a plan for dealing with changes in exchange rates and how they affect the values given by customs for industry parts. You can save money on global buying costs and speed up the process of importing industry parts for your business by managing customs and fees ahead of time.

Ensuring Compliance with International Standards

Always make sure you know and follow the rules of the place where you want to buy hardware. There are rules that the International Organization for Standardization (ISO) makes that can have an impact on your business and the things you sell. Something like this needs to be approved by UL in the US. They need a CE mark to be sold in the EU. Ask the business you work with for the right papers and licenses to make sure they follow these rules. Make sure you have a good quality control system in place so that everyone in your supply chain knows what the rules are. You should be aware of any changes to laws like REACH or RoHS (Registration, Evaluation, Authorization, and Restriction of Chemicals) that happen in the EU. Hire a third-party service to look over and test your goods to make sure they are safe and good. Checking that the items you buy meet standards from other countries is one way to be sure they are safe and of good quality. You'll also be less likely to break the law, and you'll get your money back.

Optimizing Logistics and Supply Chain Management

Developing an Efficient Transportation Strategy

Planning a good shipping system is very important when getting parts for industries around the world. To start, compare the different ways of transporting goods (by boat, air, train, or road) using criteria like price, travel time, and the nature of the goods. Utilizing a multi-modal method could help improve productivity and adaptability. Sort your orders by frequency and number to find the cheapest ways to ship them, like Less Than Container Load (LCL) or Full Container Load (FCL) for sea freight. Look into merging options to lower the cost of shipping and boost total efficiency. Establish partnerships with dependable freight forwarders and shipping companies that have dealt with parts and routes specific to your business before. Monitor goods with real-time tracking systems and take care of any problems or delays before they happen by using these systems. You can cut costs, shorten wait times, and make sure the on-time arrival of your widely found industry parts by planning your shipping strategy well.

Managing Inventory and Lead Times

Managing supplies well and getting the most out of wait times are important parts of global buying for industry parts. Use tools and methods for demand projections to correctly guess how much inventory you'll need and avoid running out of stock or having too much inventory. When deciding whether to use Just-In-Time (JIT) inventory management, you should weigh the need to save money against the need to keep extra stock on hand in case there are problems in the supply chain. Look at past records and market trends to find regular changes, then change the way you order things to reflect those changes. Communicate clearly with your providers about lead times and come up with ways to cut them down, like improving production methods or making the best use of order numbers. Use inventory management software to keep track of your stock, keep an eye on how well your suppliers are doing, and automate the process of restocking. Use backup stock methods for important parts in your industry to make sure that activities don't stop. You can lower your carrying costs, improve your cash flow, and keep your widely sourced industry parts' supply chain flexible by handling your inventory and wait times well.

Mitigating Supply Chain Risks

When getting industry parts from around the world, it's important to lower the risks in the supply chain. To begin, you should do a full risk review to find any weak spots in your supply chain, like provider reliance, nature disasters, or unstable political situations. To make sure your business stays open, you should make backup plans and find other ways to get important parts. Find and qualify several sources for key industry parts to reduce your reliance on a single source. This is called supplier diversification. To lower your risk of global supply chain problems, think about nearshoring or reshoring choices for some parts. Use advanced analytics and AI-powered tools to keep an eye on and guess at real-time supply chain risks. Protect private data and intellectual property all along your supply chain by putting in place strong protection measures. Review and update your risk management plans on a regular basis to keep up with changes in the world. You can make your global buying processes for industry parts more resilient and reliable by reducing supply chain risks ahead of time.

Conclusion

Industry parts for your business from around the world can help you save money, get access to new technologies, and be more competitive, among other things. Companies can buy things from around the world if they make good plans for finding dependable suppliers, understanding the rules of foreign trade, and improving the management of transportation and the supply chain. And it's important to keep an eye out for risks and problems and to change with the times and the rules of the market. Companies can make strong and useful global supply chains for the things they make by planning ahead, getting to know their sources well, and being committed to quality and compliance. They will do well on the global market for a long time because of this.

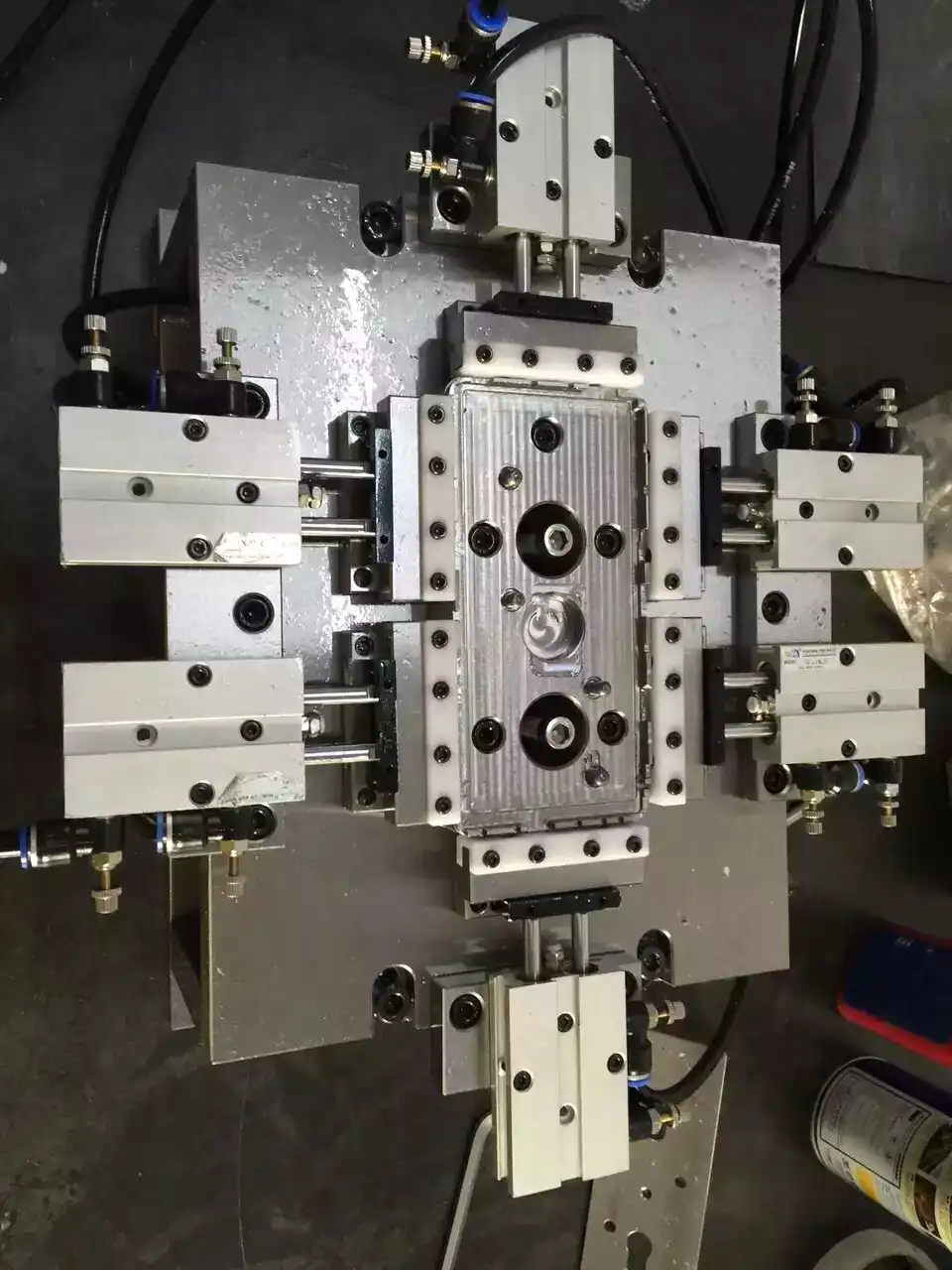

For expert assistance in sourcing industry parts globally, consider partnering with Alwin Asia Limited, a Hong Kong-registered company with extensive experience in the field. Our manufacturing facility, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., has been a trusted name in the industry since 1993. Located in Changan Town, Dongguan City, Guangdong Province, we specialize in plastic molds, die-casting molds, and plastic products. With over 300 employees and 6000 square meters of factory space, we offer comprehensive services including design, development, mold fabrication, production, and secondary processing. Our commitment to quality, competitive pricing, and on-time delivery makes us an ideal partner for your global sourcing needs. To learn more about our services or to discuss potential collaboration, please contact us at sales-c@alwinasia.com.

FAQ

Q: What are the main benefits of sourcing industry parts globally?

A: Global sourcing offers cost savings, access to innovative technologies, specialized expertise, and increased competitiveness in the international market.

Q: How can I ensure the quality of globally sourced industry parts?

A: Thoroughly evaluate suppliers, conduct audits, request samples, and implement robust quality control processes to ensure consistent product quality.

Q: What are the key challenges in global sourcing of industry parts?

A: Challenges include navigating international trade regulations, managing logistics, mitigating supply chain risks, and overcoming cultural and language barriers.

Q: How can I optimize transportation costs when sourcing industry parts globally?

A: Evaluate different transportation modes, consider consolidation opportunities, and work with experienced logistics providers to optimize costs and efficiency.

Q: What strategies can help mitigate supply chain risks in global sourcing?

A: Implement supplier diversification, develop contingency plans, utilize real-time monitoring tools, and consider nearshoring or reshoring options for critical components.

References

1. Smith, J. (2022). Global Sourcing Strategies for Manufacturing Industries. International Journal of Supply Chain Management, 15(3), 245-260.

2. Johnson, A., & Brown, L. (2021). Navigating International Trade Regulations: A Comprehensive Guide. Global Trade Review, 8(2), 112-128.

3. Lee, K. (2023). Optimizing Logistics in Global Supply Chains: Best Practices and Case Studies. Journal of Operations Management, 41(4), 567-582.

4. Chen, H., & Wang, Y. (2022). Risk Management in Global Sourcing: A Systematic Literature Review. Supply Chain Management: An International Journal, 27(1), 34-52.

5. Anderson, M., & Taylor, R. (2021). The Impact of Digital Technologies on Global Sourcing Practices. International Business Review, 30(3), 301-315.

6. Garcia, S., & Rodriguez, C. (2023). Sustainable Global Sourcing: Balancing Economic, Environmental, and Social Factors. Journal of Cleaner Production, 350, 131852.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer