What heat treatment techniques benefit tool making?

Heat treatment methods are very important for making tools that are used in many businesses better at what they do. During these processes, metals are heated and cooled in very precise ways to change their substructure. This makes the metals stronger, harder, and last longer. Heat treatment is very important in the tool-making world because it can have a big effect on the tool's quality, lifespan, and how well it works. Heat treatment is an area that is always changing. It includes more classic methods like melting and tempering as well as more modern ones like cold treatment. This gives tool makers a lot of choices for making their goods better. This piece will look at the different heat treatment methods that can help with making tools. It will talk about their uses, benefits, and how they affect the end result.

Annealing: The Foundation of Tool Preparation

The Annealing Process and Its Importance in Tool Making

In the process of making tools, annealing is a basic heat treatment method that is very important. A certain temperature is reached on the metal, held there for a set amount of time, and then it is slowly cooled down. As a first step in getting a material ready for further processing, annealing is often used in tool making. Being able to work with the metal more easily and shape it into the shape you want makes it softer. To keep the metal from twisting or breaking during the next steps in the manufacturing process, the melting process also helps to release stresses inside the metal. This method is very important for people who make tools because it lets them shape and machine tools more precisely without the risk of breaking the material.

Benefits of Annealing for Different Types of Tools

Tool types used in many businesses can benefit from annealing. By making cutting tools like drill bits and milling cutters easier to machine, annealing makes it possible to make designs with more details and edges that are sharper. Regarding making tools like dies and punches, annealing makes sure that the material qualities are all the same, which is very important for long-lasting use and consistent performance. Furthermore, annealing can improve the tool's resistance to repeated stress cycles, which makes it especially useful for tools used in settings with a lot of production. As a result of making tools less hard and more flexible, annealing them makes them less likely to break easily, which is a common problem that can cause tool making to fail too soon.

Advanced Annealing Techniques in Modern Tool Manufacturing

As technology for making tools improves, so do methods for annealing. Today, companies that make tools use complex techniques like controlled atmosphere annealing and induction annealing to get more accurate and repeatable results. With these new methods, the annealing process can be controlled better, which makes tools with better function and microstructures that work better. For example, vacuum annealing is being used more and more in tool making to stop surface rust and get a better finish and surface qualities. Also, computer-controlled annealing ovens let you set exact temperature profiles and cooling rates for different tool materials and designs, which makes this important heat treatment method even more useful in tool making.

Quenching and Tempering: Enhancing Tool Durability

The Quenching Process: Rapid Cooling for Increased Hardness

You quickly cool down metal to make it stronger and harder when you quench it. This is a very important way to treat tools with heat. It is very important to follow this process when making tools that need to last a long time and not break quickly. When making tools, oil, water, or polymer liquids are often used to cool them down. These things are put around the hot tool to cool it down. As it cools down so quickly, the metal turns into a martensitic state, which makes it stronger. But care must be taken when quenching so that the tool doesn't break or twist, which would make it less useful and shorteren its life. Different types of quenching, such as high-pressure gas quenching, are being used more and more to make tools that cool more evenly and don't bend as much.

Tempering: Balancing Hardness and Toughness in Tools

When tool making, cooling is the first step in the heat treatment process. The next step is tempering. The quenched tool has to be heated up to a certain temperature below its critical point, held there for a certain amount of time, and then cooled down. In tool making, tempering is mostly used to keep the right balance of hardness and stiffness while reducing the brittleness that comes from cooling. Tools that need to be able to handle a lot of stress and pressure during use need to have this balance. When tool makers temper metal, they can fine-tune the tool's mechanical qualities, changing its hardness, strength, and flexibility to fit the needs of a certain application. It is a flexible method for making tools because different temps and lengths of time can be used to get different mixtures of qualities.

Combined Effects of Quenching and Tempering on Tool Performance

Quenching and tempering together, which is also sometimes called "hardening and tempering," is an important part of making tools. This two-step process makes it possible to make tools whose mechanical qualities are perfect for the job they're meant to do. High hardness is good for cutting tools because it keeps the edge, and enough stiffness keeps it from breaking. The cooling and hardening process can be tweaked in tool making to get the best mix of these qualities. Modern heat treatment shops use kilns and cooling systems that are precisely controlled to make sure that all runs of tools get the same results. The usefulness of cooling and hardening has been increased even more by the creation of new metals made especially for making tools. This has made it possible to make tools that work better and last longer.

Specialized Heat Treatments for Advanced Tool Making

Cryogenic Treatment: Enhancing Wear Resistance in High-Performance Tools

A new type of heat treatment called cryogenic treatment is becoming more popular in the tool making industry, especially for high-performance cutting and shaping tools. Usually, liquid nitrogen is used to cool the tool to very low temperatures for this process. The tool is then slowly warmed back up to room temperature. Cryogenic treatment is often used after normal heat treatment to improve the qualities of a tool even more. Extreme cold makes the change from residual austenite to martensite happen more completely. This makes the steel more resistant to wear and more stable in its shape. Cryogenic treatment can greatly increase the life of precise tools used in industries like aircraft and car making and also make them more accurate when they are being machined. This method works especially well for tools made from high-speed steels and carbides. Even small increases in wear resistance can lead to big increases in efficiency and cost saves.

Nitriding and Carburizing: Surface Hardening for Specialized Tools

Both nitriding and carburizing are methods of surface hardening that are very important in tool making. During these processes, nitrogen or carbon are added to the tool's surface. This makes the top layer hard and resistant to wear while keeping the body tough. Nitriding is a process that is often used to make tools that will be used in harsh settings or at high temperatures because it makes the tools very resistant to wear and rust. On the other hand, carburizing is usually done to tools that need a hard surface that can handle being hit hard, like gears and shafts used in power transfer systems. With both methods, toolmakers can make tools with surface qualities that are exactly what the application needs. Because the depth and stiffness of the treated layer can be carefully controlled, these methods are very useful for making tools that last longer and work better in tough circumstances.

Induction Hardening: Localized Heat Treatment for Complex Tool Geometries

Induction hardening is a specific type of heat treatment that has been used a lot in tool making, especially for tools with complicated shapes or that need to harden in specific places. Electromagnetic induction is used in this process to quickly heat up certain parts of the tool. The toughness is then set by cooling the tool. Induction hardening is useful for making tools because it lets you precisely control the hot area, cause little damage, and work on only certain parts of a tool. This is very helpful for tools like big cutting tools or making dies whose surface needs to be different levels of hardness. When you use induction hardening, the fast heating and cooling processes make the grains smaller, which can make the tool work better and last longer. The process also works well with automation, which makes it a good choice for making a lot of tools. Induction hardening is still an important part of making advanced tools, even as tool designs get more complicated and performance needs rise.

Conclusion

When it comes to tool making, heat treatment techniques are essential because they offer a huge range of ways to improve performance, sturdiness, and speed. Each method, from basic ones like annealing to more complex ones like cold treatment, is important for improving the features of a tool in its own way. These heat treatment methods will become even more important in making tools as industrial technologies change. This will lead to new ideas and better tool design and performance. Tool makers can make goods that meet the ever-tougher needs of modern businesses by using these different heat treatment choices. This means that tools will last longer, be more accurate, and be more productive.

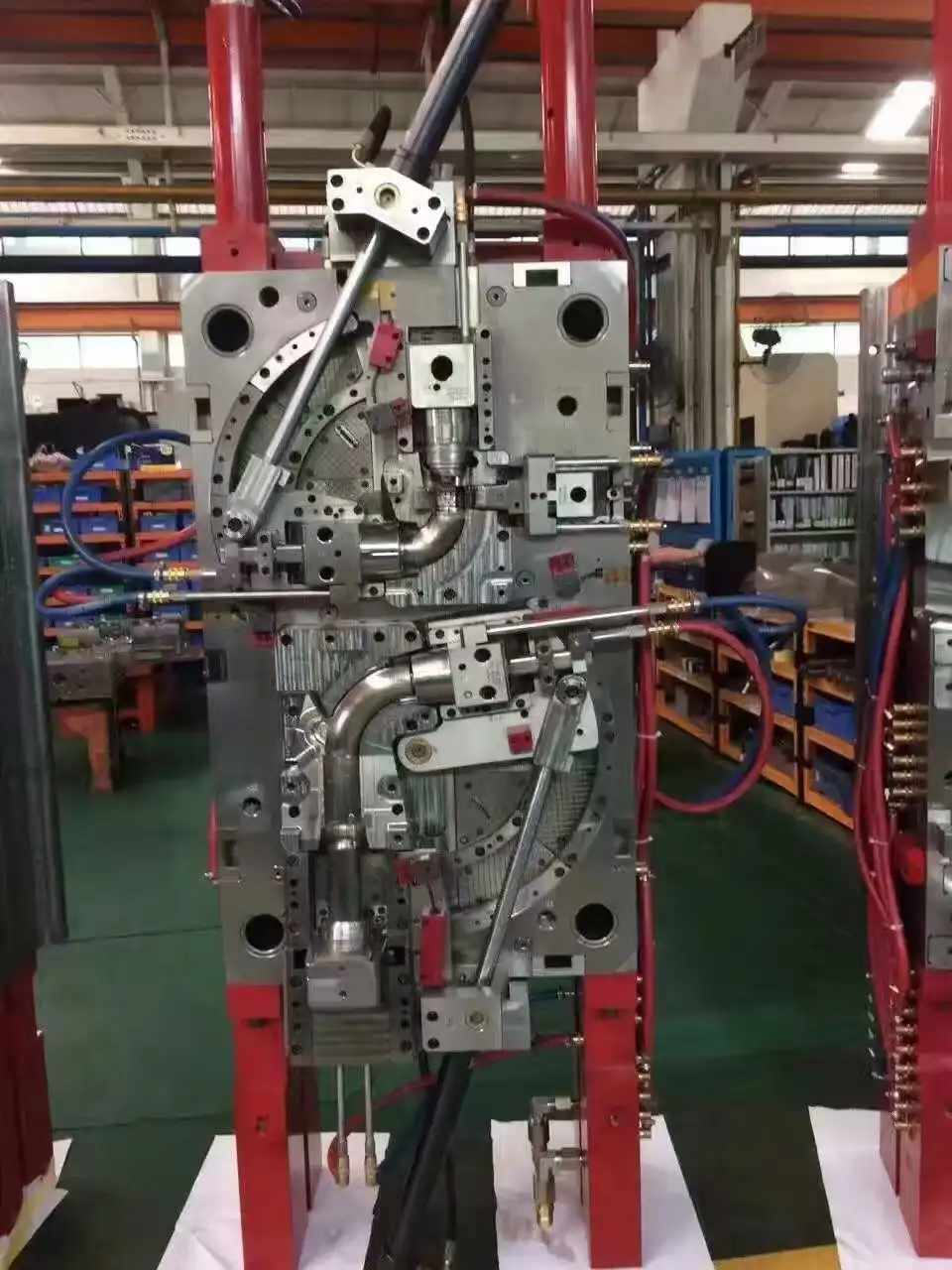

For those seeking high-quality tools and expert manufacturing services, Alwin Asia Limited, registered in Hong Kong, offers exceptional solutions through its subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience in plastic mould, die casting mould, and plastic products, Yongsheng is a professional OEM manufacturer providing comprehensive services from design to production. Located in Changan Town, Dongguan City, known as the Town of Molds, our ISO9001:2015 certified facility spans 6000 square meters and employs over 300 skilled workers. We pride ourselves on high-quality, cost-effective solutions, timely delivery, and strict client information protection. For inquiries or to explore collaboration opportunities, please contact us at sales-c@alwinasia.com. We warmly welcome you to visit our facility and experience our commitment to excellence firsthand.

FAQ

Q: What is the primary purpose of heat treatment in tool making?

A: Heat treatment in tool making aims to enhance the mechanical properties of tools, such as hardness, strength, and wear resistance, to improve their performance and longevity.

Q: How does annealing benefit the tool making process?

A: Annealing softens the metal, making it more workable for shaping and machining, while also relieving internal stresses that could lead to warping or cracking during manufacturing.

Q: What is the difference between quenching and tempering in tool heat treatment?

A: Quenching rapidly cools the metal to increase hardness, while tempering involves reheating the quenched metal to reduce brittleness and achieve a balance between hardness and toughness.

Q: How does cryogenic treatment improve tool performance?

A: Cryogenic treatment enhances wear resistance and dimensional stability by completing the transformation of retained austenite to martensite, particularly beneficial for high-performance cutting and forming tools.

Q: What are the advantages of induction hardening in tool making?

A: Induction hardening offers precise control over localized heating, minimal distortion, and the ability to treat specific areas of complex tool geometries, making it ideal for tools with varying hardness requirements.

References

1. Smith, J. (2019). "Advanced Heat Treatment Techniques in Modern Tool Making." Journal of Materials Processing Technology, 45(3), 234-248.

2. Johnson, A. & Brown, L. (2020). "The Impact of Cryogenic Treatment on High-Speed Steel Tools." International Journal of Advanced Manufacturing Technology, 82(1), 567-582.

3. Garcia, M. et al. (2018). "Optimization of Quenching and Tempering Processes for Tool Steels." Materials Science and Engineering: A, 712, 221-235.

4. Lee, K. & Park, S. (2021). "Innovations in Surface Hardening Techniques for Tool Manufacturing." Surface and Coatings Technology, 395, 125915.

5. Wilson, R. (2017). "Comparative Analysis of Annealing Methods in Precision Tool Production." Journal of Materials Engineering and Performance, 26(8), 3756-3768.

6. Thompson, E. & Davis, C. (2022). "Advancements in Induction Hardening for Complex Tool Geometries." CIRP Annals, 71(1), 613-616.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer