If you are planning to get an injection mold from China, it is vital that you carefully analyze suppliers that have expertise in meeting the specific manufacturing needs that you have. The most crucial factor is choosing suppliers who not only have the most advanced mold design capabilities but also have reliable production techniques and rigorous quality assurance systems. Chinese mold manufacturers provide competitive cost advantages, and they also comply with the quality criteria that are established on a global scale. This is particularly the case when you develop a collaboration with established businesses that have a proven track record of supplying services to the worldwide electronics, automotive, and consumer goods sectors.

Understanding China's Injection Molding Manufacturing Landscape

Guangdong Province has taken the lead in this shift, which has enabled China to become the largest hub for plastic injection production in the world. There are thousands of specialist facilities in this area, all of which are outfitted with cutting-edge injection molding equipment as well as sophisticated mold design software. Dongguan City, which is often referred to as the "Town of Molds," is home to a large number of experienced manufacturers who have been perfecting their injection molding techniques for many years.

The competitive advantage extends beyond cost savings. Chinese manufacturers have invested heavily in precision machinery, automated production lines, and skilled technicians who understand complex mold cavity requirements. Many facilities now rival European and American counterparts in terms of technological capabilities and production efficiency.

The capacity to manage entire project lifecycles is the characteristic that sets apart the most prominent suppliers in China. From the first consultation for the design of plastic parts all the way to the final delivery, these manufacturers offer integrated services that make the procurement process more efficient for international purchasers.

Essential Criteria for Evaluating Injection Mold Suppliers

Manufacturing experience stands as the primary indicator of supplier reliability. Companies with extensive histories demonstrate their ability to navigate market fluctuations while continuously improving their processes. Look for manufacturers who have served diverse industries and can showcase successful projects similar to your requirements.

An further essential standard is provided by the certification of quality. Certifications that are specific to a certain industry are an indication of specialist knowledge, while the presence of the ISO 9001:2015 certification is an indicator of systematic quality management systems. It is not uncommon for providers who are considered to be of a higher caliber to possess supplementary certificates that demonstrate their dedication to adhering to international standards.

Production capacity assessment involves examining both equipment capabilities and workforce expertise. Modern injection molding machines with precise clamping force control ensure consistent part quality. Equally important is the technical team's ability to optimize injection pressure, cycle time, and mold temperature for your specific thermoplastic injection requirements.

Among respected Chinese producers, the measures that are used to protect intellectual property have become increasingly complex. In order to safeguard their customers' ideas and designs during the production and mold design phases, the most prominent corporations adopt thorough confidentiality rules and maintain secure design databases.

Technical Capabilities That Matter Most

Advanced mold design software utilization separates professional manufacturers from basic suppliers. Companies employing CAD/CAM systems can optimize runner system layouts, predict potential injection molding defects, and simulate the complete injection molding cycle before production begins.

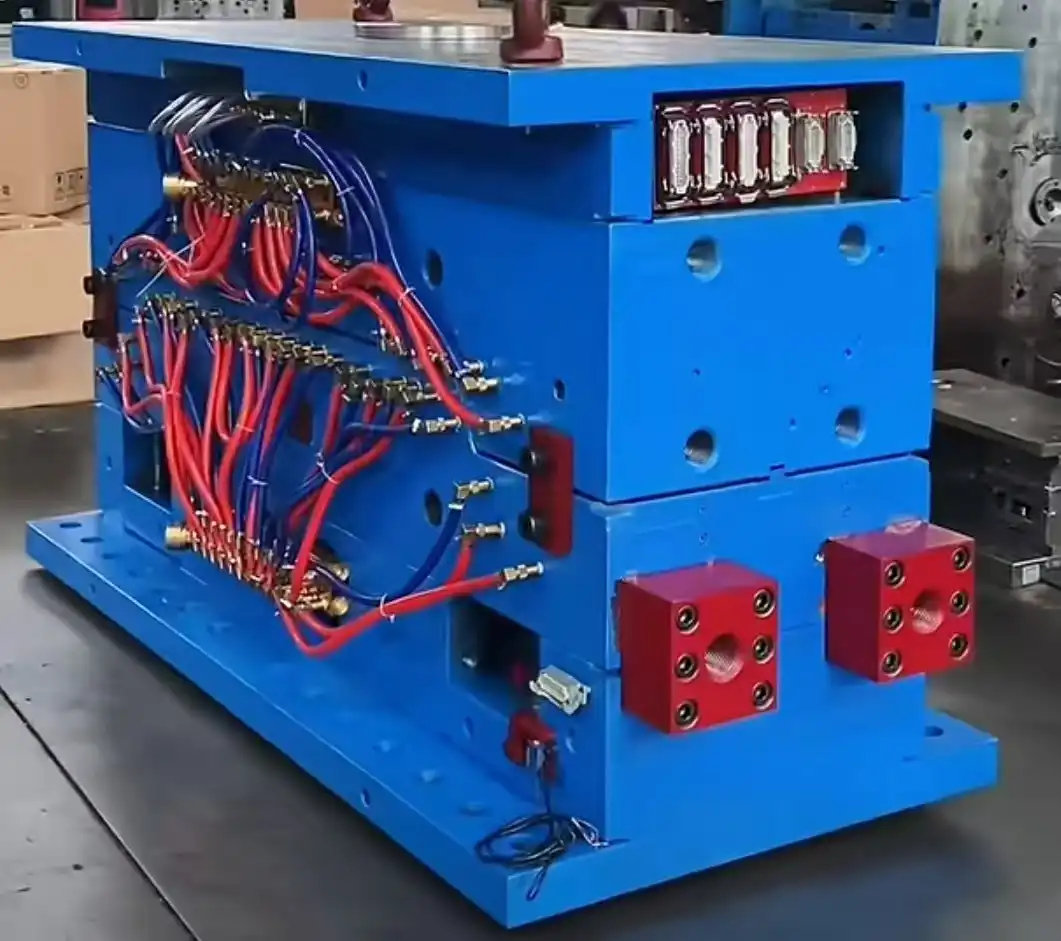

Hot runner system expertise indicates advanced technical capabilities. These systems reduce material waste, improve cycle time efficiency, and enable better temperature control across complex mold cavities. Suppliers familiar with hot runner technology typically handle more sophisticated projects.

Precision machining capabilities determine the final quality of your injection mold. EDM equipment, CNC machining centers, and coordinate measuring machines ensure dimensional accuracy that meets tight tolerances required for automotive and electronics applications.

Secondary processing capabilities add significant value to supplier relationships. Manufacturers offering assembly, packaging, and logistics services reduce your coordination burden while maintaining quality control throughout the entire production chain.

Quality Control and Testing Procedures

Comprehensive quality assurance begins with incoming material inspection. Reputable manufacturers verify plastic injection materials against specifications before production starts. This prevents costly delays and ensures consistent part properties throughout production runs.

In-process monitoring systems track critical parameters including injection speed, mold cooling efficiency, and ejector pins operation. Real-time data collection enables immediate adjustments that maintain quality standards and prevent defective parts.

Final inspection protocols should include dimensional verification, surface finish assessment, and functional testing where applicable. Advanced suppliers provide detailed quality reports documenting compliance with your specifications.

Sample approval processes protect both parties by establishing clear quality expectations. Professional manufacturers provide samples that accurately represent full production capabilities, complete with material certifications and dimensional reports.

Communication and Project Management Excellence

Effective communication bridges cultural and linguistic gaps that can complicate international sourcing. Leading Chinese manufacturers employ English-speaking project managers who understand Western business practices and technical requirements.

Project transparency involves regular progress updates, milestone reporting, and proactive problem communication. Suppliers who maintain open communication channels help you manage internal timelines and coordinate with other project stakeholders.

Technical support capabilities extend beyond initial production. Manufacturers offering ongoing maintenance guidance, troubleshooting assistance, and modification services provide long-term value that justifies supplier relationships.

Consistent response times are an indication of professional project management strategies. Suppliers who are reliable put into place communication mechanisms that guarantee that they will respond in a timely manner to questions, requests for modifications, and other matters that require immediate attention.

Cost Analysis and Value Proposition

Total cost evaluation encompasses more than initial tooling prices. Factor in shipping costs, customs duties, potential modification expenses, and long-term maintenance requirements when comparing supplier proposals.

Payment term flexibility reflects supplier confidence and financial stability. Established manufacturers often accommodate milestone-based payment schedules that align with project progress and reduce financial risks for both parties.

Hidden cost identification prevents budget overruns. Clarify whether quotes include design modifications, sample production, testing services, and shipping arrangements. Transparent pricing demonstrates professional business practices.

Services that provide value can compensate for increased upfront expenses. Expertise that enhances the quality of the final product as well as the product's manufacturability is provided by suppliers who offer services such as design optimization, material selection help, and production advising.

Due Diligence and Supplier Verification

Factory audits provide firsthand insight into supplier capabilities and working conditions. Virtual tours and detailed facility documentation can substitute for physical visits when travel restrictions apply.

Reference verification through existing clients offers objective performance assessments. Reputable manufacturers willingly provide client contacts who can discuss their experiences with quality, delivery, and customer service.

Financial stability assessment protects against supplier disruptions. Companies with strong financial foundations invest in equipment upgrades, workforce training, and quality improvements that benefit your projects.

Regulatory compliance verification ensures your supplier meets environmental and safety standards. This becomes particularly important for automotive and medical device applications requiring specific certifications.

Conclusion

A successful search for injection mold suppliers in China relies on careful assessment of suppliers as well as clearly conveying what your needs are. It is recommended that your attention be directed toward those manufacturers who have a history of success, possess advanced technical capabilities, and have thorough quality assurance methods. A significant return on investment is achieved through the practice of thorough due diligence. The benefits of this investment include lower risks, higher quality results, and more robust supplier partnerships. When you find the proper supplier in China who has a solid understanding of your industry's requirements and your business's priorities, you can take advantage of the excellent prospects that the country's manufacturing environment offers for cost-effective, high-quality injection molding solutions.

Partner with Yongsheng: Your Trusted Injection Mold Manufacturer

For every injection mold project, Yongsheng contributes more than thirty years of specialized experience, blending traditional craftsmanship with contemporary production excellence. As members of the Dongguan City Hardware Machinery Mould Industry Association's council, we strive to uphold the best standards in the industry while also providing cost-effective solutions for a variety of industries, including electronics, automotive, and consumer products.

Our 6,000-square-meter building has state-of-the-art injection molding machines, precision machining centers, and a lot of tools for quality control. The operations that have been approved in line with ISO 9001:2015 will make sure that every part of your project is done to a consistently high standard, from the initial mold design to the final delivery. Our team of more than 300 skilled professionals is here to help you at any time during the course of your project. The fact that these experts have worked in foreign procurement for a long time means that they understand how complicated the field is.

We understand the critical importance of intellectual property protection and maintain strict confidentiality protocols that safeguard your innovations. Our proven track record serving international clients demonstrates our commitment to on-time delivery and transparent communication that builds lasting partnerships. Ready to discuss your injection mold requirements? Contact us at sales@alwinasia.com to explore how our expertise can optimize your next project.

References

1. Smith, J.A. (2023). "Global Injection Molding Market Analysis: China's Manufacturing Dominance." International Plastics Manufacturing Review, Vol. 45, pp. 78-92.

2. Chen, L. & Rodriguez, M. (2024). "Quality Standards in Chinese Injection Molding: ISO Compliance and International Best Practices." Journal of Manufacturing Excellence, Vol. 18, No. 3, pp. 156-171.

3. Thompson, R.K. (2023). "Supplier Selection Strategies for International Mold Procurement." Procurement Management Quarterly, Vol. 29, pp. 45-58.

4. Wang, H. et al. (2024). "Technological Advancement in Chinese Injection Molding Facilities: A Comprehensive Assessment." Asian Manufacturing Technology Journal, Vol. 12, pp. 203-218.

5. Miller, S.D. (2023). "Cost Analysis Framework for International Injection Mold Sourcing." Supply Chain Management Today, Vol. 31, No. 4, pp. 89-104.

6. Liu, Y. & Brown, P. (2024). "Intellectual Property Protection in Chinese Manufacturing Partnerships." International Business Law Review, Vol. 56, pp. 234-249.