When procurement managers have to choose between Japan and China to get automotive parts, they have to make a tough choice that affects their whole OEM strategy. China is clearly the best place to make high-volume, low-cost automotive parts because it offers great value without sacrificing quality. Japanese makers are great at precise engineering, but when they work on big projects, they often go over budget. Chinese suppliers like Yongsheng offer full OEM services, from the initial design phase to the final production phase. This makes them the perfect partners for businesses that need custom metal and plastic automotive parts at reasonable prices.

Understanding OEM/ODM Solutions for Automotive Manufacturing

Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) are two different ways to make parts for cars. OEM is the process of making parts based on what the customer wants, while ODM is the whole process of designing and developing the product. These days, automakers want partners who can handle both methods without any problems.

The automotive parts requires suppliers capable of producing everything from engine components to transmission systems with precise specifications. Deep customization matters because every vehicle model demands unique parts that meet specific performance standards. Brake pads for luxury vehicles differ significantly from those designed for commercial trucks, requiring specialized manufacturing capabilities.

Suppliers of car parts that want to be successful need to understand how to navigate complicated supply chains, meet quality standards, and follow government rules. The difference between great producers and average ones is their ability to quickly increase production while keeping quality levels stable. This knowledge is very important when looking at possible sourcing places.

China's Competitive Advantages in Automotive OEM Manufacturing

Within the last twenty years, Chinese companies that make car parts have changed a lot, becoming world leaders in producing goods at low costs. Yongsheng, who has been in business for more than 30 years and is a member of the Dongguan Hardware Machinery Mould Industry Association and has ISO9001:2015 certification, is a good example of this change.

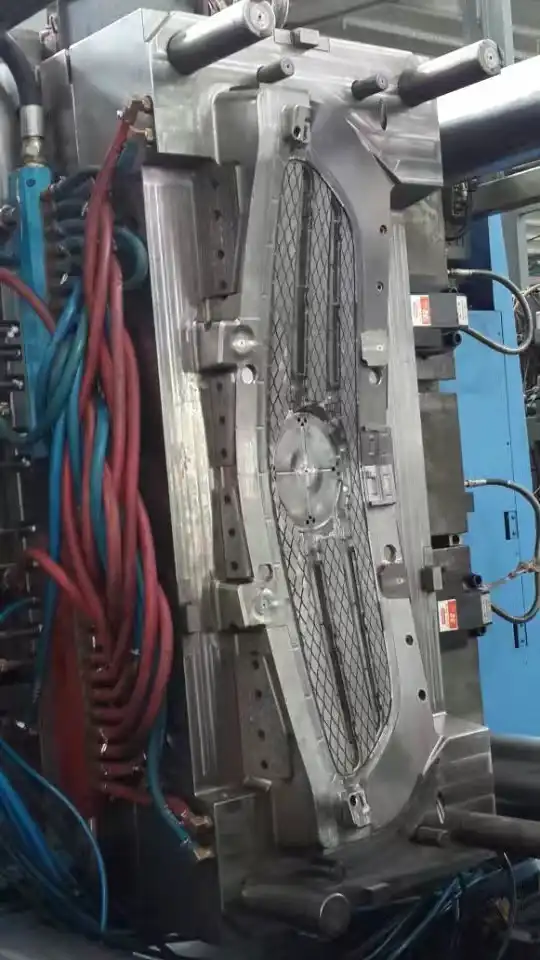

China has better manufacturing facilities than most other countries in the world, both in terms of size and level of technology. Chinese suppliers can efficiently handle complicated auto parts because they have advanced injection molding tools, precise die-casting capabilities, and automatic assembly lines. Having a lot of suppliers in places like Dongguan that are known for making things lowers prices and speeds up delivery times.

Chinese makers have put a lot of money into hiring engineers and buying high-tech testing gear, which has made their research and development much better. Many facilities now use Six Sigma methods and statistical process control to make their quality control systems meet foreign standards. Integration of the supply chain makes it possible to make prototypes and changes to designs quickly, which is very helpful in the fast-paced car industry.

Another important strength is scalability, which means that Chinese producers can quickly change the amount of goods they make to meet changing market needs. This freedom is very helpful when a new product comes out or when sales of cars change with the seasons.

Comprehensive Customization Capabilities

Customizing a physical design goes beyond just changing the size; it can also involve complicated shapes and combining different materials. Specialized materials that can handle high temperatures, chemicals, and mechanical stress are often needed for auto parts. Parts for suspension, clutch assemblies, and steering mechanisms need exact engineering that strikes a balance between performance and cost.

Adding electronic parts, sensors, and smart technologies to regular auto parts is what functional features customization means. These days, fuel injection systems have complex electrical controls that need to be made using special methods. Catalytic converters and pollution monitoring devices are now part of exhaust systems and need to be manufactured with very tight tolerances.

Technology integration has become increasingly important as vehicles incorporate more electronic systems. Air filters now include sensors for monitoring replacement intervals, while spark plugs feature advanced materials for improved performance. Manufacturers must stay current with emerging technologies to remain competitive.

Branding customization allows automotive companies to maintain consistent visual identity across all components. Custom packaging solutions protect parts during shipping while reinforcing brand recognition. Compliance customization ensures all parts meet regional safety standards and environmental regulations.

The Strategic ODM Advantage

Through ODM partnerships, automakers can use specialized engineering knowledge without having to keep big design teams on staff. Using ODM relationships to co-develop new car parts speeds up innovation and lowers the cost of development. This strategy works especially well for businesses that are entering new markets or making specific apps.

Collaborative engineering processes allow for rapid iteration and optimization of designs before committing to production tooling. Advanced simulation software enables virtual testing of components under various operating conditions. This capability reduces the risk of costly design changes during later development stages.

Market responsiveness improves significantly through ODM partnerships, as experienced manufacturers understand industry trends and emerging technologies. Timing belt designs evolve continuously as engine technologies advance, requiring suppliers who stay current with automotive engineering developments.

When manufacturers use their specific knowledge to help develop new products, innovation speeds up. Manufacturing experts who know how to choose the right materials and optimize heat movement can help with radiator designs. When compared to traditional customer-specified manufacturing, this collaborative method often leads to better products.

Our Proven OEM/ODM Process

The process of customization starts with a thorough meeting to find out exactly what the project needs and what its limits are. The first things that are talked about are the specifications of the materials, the performance goals, the regulatory requirements, and the output volumes for automotive parts. Review meetings for designs make sure that everyone involved is on the same page with the project's goals and technical approaches.

Developing a prototype follows standard engineering practices, and at each stage, customer feedback is taken into account. Rapid tooling for small-batch testing and validation is an advanced development feature. Testing the materials makes sure that all of the parts meet the performance standards in the real world.

Production planning involves detailed scheduling coordination to meet delivery deadlines. Tooling design and fabrication require careful attention to production efficiency and quality consistency. Process validation includes comprehensive testing to verify all quality standards are met consistently.

Quality assurance protocols encompass incoming material inspection, in-process monitoring, and final product verification. Statistical process control ensures consistent quality throughout production runs. Documentation systems maintain complete traceability for all automotive components.

Delivery coordination includes packaging optimization for international shipping and customs clearance support. Post-delivery support ensures customer satisfaction and addresses any technical questions that arise during assembly or installation.

Strategic Benefits for Your Automotive Projects

By outsourcing production to China, you can cut costs and get big benefits without lowering quality standards. Finding materials more cheaply and hiring workers more efficiently directly lead to higher project profits. For larger orders, volume discounts are possible, which makes the price even more cost-effective.

Time-to-market is sped up by streamlining the research process and quickly increasing the size of production. Expert manufacturers know how to optimize the critical path and can spot possible bottlenecks before they cause delivery schedules to slip. This quickness is very important in markets for cars that are very competitive.

Quality assurance methods give people faith in the dependability and consistency of products. Advanced testing tools make sure that all parts meet strict car standards. Continuous improvement programs make sure that production processes and product performance are always getting better.

Supply chain reliability reduces risk through diversified sourcing strategies and established vendor relationships. Backup suppliers and alternative materials ensure production continuity even during unexpected disruptions. This resilience proves essential for maintaining automotive production schedules.

Technical help is available at all stages of a product's life, from the initial design phase to ongoing production. Engineering help is still available to make changes to designs or make processes better. This long-term partnership model builds trust and makes it possible to keep improving.

Conclusion

When it comes to buying auto parts, the choice between Japan and China comes down to your unique project needs, budget, and long-term goals. Japanese makers have great precision engineering, but Chinese suppliers are much more cost-effective, can grow with your business, and offer full OEM/ODM services. Companies like Yongsheng show that Chinese car parts manufacturing has changed over the years to meet the highest quality standards while keeping prices low. The key to success is choosing partners with a lot of experience who know what the automotive industry needs and can consistently achieve results. You can get the best results from your automotive parts projects and build long-lasting competitive benefits in the market by carefully evaluating your needs and selecting the right manufacturing partner.

Partner with Yongsheng for Your Automotive Parts Manufacturing Success

With its full OEM and ODM capabilities, Yongsheng is ready to make your vision for automotive parts come true. Our 30-year history of manufacturing and cutting-edge technology work together to give automotive companies around the world the best results possible. We have unbeatable access to specialized suppliers and advanced production capabilities because we are located in Dongguan's well-known manufacturing hub.

Since you trust us to provide you with car parts, we know how important accuracy, dependability, and low cost are in today's market. Our experienced engineers work closely with customers to make sure that plans are optimized so that they can be made while still meeting high performance standards. Quality systems make sure that every part meets the strict standards of the automotive business.

Take the next step toward manufacturing excellence by partnering with an established automotive parts manufacturer who understands your unique challenges. Whether you need custom engine components, suspension parts, or complete assemblies, our comprehensive capabilities deliver results that exceed expectations. Contact us at sales@alwinasia.com to discuss your automotive parts project requirements and discover how our expertise can accelerate your success.

FAQ

Q: How does Chinese automotive parts quality compare to Japanese standards?

A: Modern Chinese automotive parts manufacturers like Yongsheng maintain quality standards comparable to international competitors through ISO certification, advanced testing equipment, and rigorous quality control processes. The key lies in selecting experienced manufacturers with proven track records and appropriate certifications.

Q: What lead times can I expect for custom automotive parts from Chinese suppliers?

A: Lead times typically range from 4-8 weeks for standard automotive components, depending on complexity and order volume. Prototype development usually requires 2-3 weeks, while production tooling may take 3-4 weeks. Rush orders can often be accommodated with appropriate planning.

Q: How do you protect intellectual property for custom automotive designs?

A: IP protection involves comprehensive non-disclosure agreements, secure data handling protocols, and controlled access to design information. Reputable manufacturers maintain strict confidentiality standards and understand the importance of protecting customer innovations throughout the development and production process.