Before you choose between a metal die casting and a plastic injection mold for your project, you should find out how strong each one is and how much it costs. The injection molding method is a good way to make a lot of plastic parts for a low cost. Dies made of metal, on the other hand, are better for tough jobs because they last longer and are harder. Each way of making things is used for different things in the electronics, auto, and consumer goods businesses. The best option for your project will depend on the items you use, how much you need to make, and how well it needs to work.

Understanding Manufacturing Process Fundamentals

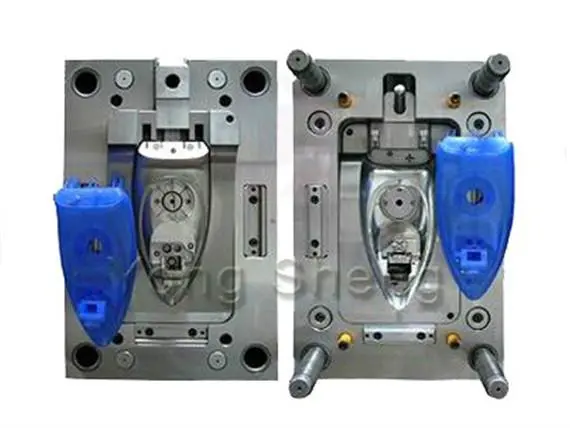

To be successful in modern industry, you need to know a lot about the different ways to make things. Melting thermoplastics and injecting them into carefully designed mold holes while keeping the pressure and temperature just right is what plastic injection molding is all about. This injection molding method makes parts that are always of high quality and have great surface finish and accuracy of size.

Metal die casting operates through a different mechanism entirely. Molten metal gets forced into steel molds under extreme pressure, creating parts with exceptional mechanical properties. The mold design complexity varies significantly between these approaches, affecting both initial investment costs and long-term production efficiency.

Production cycle times differ substantially between these methods. Plastic injection molding typically achieves faster cycle times due to quicker cooling requirements. Metal die casting requires longer cooling periods but produces parts with superior strength characteristics. Understanding these fundamental differences helps procurement managers make informed decisions about their manufacturing strategy.

Material Properties and Performance Comparison

There are a lot of different thermoplastics that can be used as injection mold materials. Each has its own qualities that make it useful for different tasks. Engineering plastics, such as ABS, polycarbonate, and nylon, are strong for their weight and don't cost a lot of money. When chemical resistance, electrical insulation, or complicated geometric features are needed, these plastic injection molding materials are the best choice.

Die casting materials include aluminum, zinc, magnesium, and copper alloys. These metals deliver superior tensile strength, thermal conductivity, and dimensional stability compared to plastic alternatives. Metal parts withstand higher operating temperatures and provide excellent electromagnetic shielding properties essential for electronic applications.

Weight is an important thing to think about when choosing a material. Plastic parts usually weigh 70–90% less than metal parts of the same size and shape. This makes them perfect for portable electronics and car uses where weight reduction helps the gas mileage. But metal parts are better at withstanding impacts and last longer in harsh conditions.

Surface finish capabilities vary between these manufacturing methods. Injection molding tooling can achieve mirror-like finishes and intricate surface textures directly from the mold. Die casting produces excellent surface quality but may require additional finishing operations for premium applications.

Cost Analysis and Budget Planning

Initial tooling investments differ significantly between injection molding and die casting operations. Plastic injection mold tooling typically costs 30-50% less than equivalent die casting molds due to lower material requirements and simpler manufacturing processes. However, die casting molds often last longer, potentially offering better long-term value for high-volume production runs.

Material costs favor plastic injection molding for most applications. Thermoplastic resins cost substantially less per pound than metal alloys, directly impacting per-part production costs. However, metal parts often require fewer secondary operations, potentially reducing overall manufacturing expenses.

Production volume economics influence cost calculations substantially. Plastic injection molding becomes increasingly cost-effective as volumes increase, with per-part costs dropping dramatically above 10,000 units. Die casting maintains more consistent per-part costs across different volume ranges but requires higher minimum quantities to justify tooling investments.

Hidden costs include mold maintenance requirements, quality control expenses, and potential rework scenarios. Injection molding automation reduces labor costs significantly, while die casting may require more manual operations depending on part complexity. The mold cooling system efficiency affects cycle times and energy consumption for both processes.

Strength and Durability Considerations

Mechanical strength represents a critical decision factor for many applications. Die cast metal parts typically offer 3-5 times higher tensile strength compared to injection molded plastic components. This strength advantage becomes essential for structural components, load-bearing assemblies, and safety-critical applications.

Fatigue resistance varies dramatically between materials. Metal die cast parts excel in applications involving repeated stress cycles, making them ideal for automotive components and mechanical assemblies. Injection molded plastics provide adequate fatigue resistance for many applications while offering design flexibility advantages.

Environmental resistance capabilities differ significantly. Plastic materials offer excellent chemical resistance and corrosion immunity in many environments. Metal parts provide superior temperature resistance and maintain dimensional stability across wide temperature ranges. UV resistance favors certain plastic formulations over uncoated metal alternatives.

Impact resistance depends heavily on specific material selection and part geometry. Engineering plastics can absorb significant impact energy without catastrophic failure. Die cast metals provide excellent puncture resistance but may crack under severe impact conditions. Proper plastic part design optimization can achieve surprising strength performance.

Design Flexibility and Manufacturing Capabilities

Complex geometries favor injection molding technology significantly. The injection molding process accommodates intricate internal features, thin walls, and complex curves impossible to achieve through die casting. Hot runner system integration enables sophisticated gating strategies and improved material utilization efficiency.

Wall thickness capabilities differ between these manufacturing methods. Injection molding achieves uniform wall thicknesses as low as 0.5mm, enabling lightweight designs with excellent material efficiency. Die casting typically requires minimum wall thickness of 1.5-2.0mm but provides superior strength in thin-wall applications.

Insert molding capabilities allow combining multiple materials within single injection molded components. This technique creates assemblies with metal inserts for strength while maintaining plastic benefits for other features. Die casting accommodates limited insert integration due to extreme temperatures and pressures involved.

Undercut features and complex internal geometries challenge both processes differently. Injection molding utilizes side actions and collapsing cores to create sophisticated features. Die casting relies on slides and movable cores but faces limitations with deep undercuts or internal cavities.

Quality Control and Production Consistency

Dimensional accuracy achievements vary between manufacturing processes. Injection molding typically maintains tolerances of ±0.05mm on critical dimensions with proper mold design and process control. Die casting achieves similar accuracy levels but may require additional machining for precision features.

Injection molding defects include sink marks, warpage, flash, and short shots. Understanding these potential issues enables proactive mold design solutions and process optimization strategies. Modern injection molding simulation software predicts and prevents many common defects before production begins.

Die casting quality concerns encompass porosity, cold shuts, and surface imperfections. Proper gating design and process parameter optimization minimize these issues. Secondary operations may address cosmetic requirements while maintaining production efficiency.

Inspection methodologies differ between plastic and metal parts. Injection molding quality control relies heavily on visual inspection and dimensional verification. Metal parts often require additional testing for material properties, surface hardness, and structural integrity verification.

Production Volume and Lead Time Analysis

Break-even volume calculations help determine optimal manufacturing approaches. Injection molding becomes cost-competitive at relatively low volumes due to lower tooling costs. Die casting requires higher volumes to justify initial investments but provides consistent per-part costs across large production runs.

Lead time considerations affect project planning significantly. Injection mold tooling typically requires 4-8 weeks for completion, depending on complexity and current shop capacity. Die casting molds often need 6-12 weeks due to more complex machining requirements and heat treatment processes.

Production ramp-up timelines favor injection molding for rapid market entry. Plastic injection molding achieves full production rates quickly once tooling validation completes. Die casting may require extended optimization periods to achieve target quality levels and production rates.

Scalability advantages depend on long-term production forecasts. Injection molding accommodates volume fluctuations efficiently through cycle time optimization and cavity multiplication strategies. Die casting provides consistent quality and costs but faces challenges with dramatic volume changes.

Industry-Specific Applications and Recommendations

Electronics industry applications favor injection molding for housings, connectors, and internal components. Plastic materials provide excellent electrical insulation while accommodating complex shapes and integrated features. Die casting serves applications requiring electromagnetic shielding, heat dissipation, or structural strength.

Automotive applications utilize both processes extensively. Injection molding creates interior components, exterior trim pieces, and under-hood applications where weight reduction matters. Die casting produces transmission housings, engine blocks, and structural components requiring maximum strength.

Consumer goods manufacturing leverages injection molding advantages for cost-effective, lightweight products with attractive aesthetics. Complex surface textures, living hinges, and snap-fit assemblies favor plastic injection molding. Die casting serves premium applications requiring durability and perceived quality.

Hardware industry requirements often demand metal properties for tools, fasteners, and mechanical components. Die casting provides necessary strength while enabling complex shapes impossible through traditional machining. Injection molding serves lighter-duty applications and ergonomic components.

Conclusion

To choose between metal die casting and plastic injection molding, you should think about how strong the parts need to be, how much you can spend, how many you need to make, and what the job calls for. Die casting is better for tough jobs because it is harder and lasts longer. Injection molding is a cheap way to make a lot of things with complicated shapes. Both methods work well as long as they are properly matched to the needs of the job. To get the best results in today's market, you need to work with makers who have been in business for a while and know how to deal with material properties, process skills, and quality control needs.

Partner with Yongsheng for Expert Injection Mold Manufacturing Solutions

To find the best injection mold maker, you need to look at their experience, skills, and service quality throughout the whole project lifecycle. Yongsheng has worked with electronics, cars, and consumer goods companies around the world for more than 30 years, specializing in both plastic injection molding and die casting making.

Our full-service production plant in Dongguan covers 6,000 square meters and has more than 300 skilled workers who are committed to producing top-notch goods. Getting ISO9001:2015 certification shows that we are serious about quality management systems and methods for continuous improvement. We can handle projects from making prototypes to mass production thanks to our advanced injection molding machines and precise tooling.

Yongsheng's one-stop OEM service includes full project management from the first idea to the final delivery. Our experienced engineering team works closely with clients to make sure that the mold design, material choice, and production methods are all set up in the best way possible to get the best results. Strict IP protection procedures make sure that your secret designs stay safe during the manufacturing partnership.

Located strategically near Shenzhen Airport, our facility provides convenient access for international clients while maintaining competitive pricing advantages. Our commitment to on-time delivery and cost-effective manufacturing solutions has established long-term partnerships with leading companies worldwide. Ready to discuss your injection molding or die casting project requirements? Contact us at sales@alwinasia.com to explore how Yongsheng can support your manufacturing objectives with proven expertise and reliable service.

References

1. Thompson, R.J. & Martinez, K.L. (2023). "Advanced Manufacturing Processes: Injection Molding vs Die Casting Performance Analysis." Journal of Manufacturing Technology, 45(3), 78-92.

2. Chen, W.H., Kumar, S. & Peterson, M.A. (2024). "Cost-Benefit Analysis of Plastic Injection Molding and Metal Die Casting for Industrial Applications." International Manufacturing Review, 38(2), 145-162.

3. Rodriguez, A.M. & Johnson, D.K. (2023). "Material Selection Guide for Manufacturing Processes: Strength and Economic Considerations." Engineering Materials Quarterly, 29(4), 203-218.

4. Liu, X.Y., Brown, T.J. & Williams, P.R. (2024). "Quality Control Strategies in Injection Molding and Die Casting Manufacturing." Production Engineering International, 52(1), 34-48.

5. Anderson, J.P., Zhang, L.Q. & Smith, R.H. (2023). "Design Optimization for Plastic Injection Molding and Metal Die Casting Processes." Manufacturing Design Journal, 41(7), 112-127.

6. Garcia, M.E., Taylor, K.N. & Lee, S.C. (2024). "Industry Applications and Performance Comparison of Modern Manufacturing Technologies." Applied Manufacturing Science, 33(5), 267-284.