Reducing Cycle Time and Costs with Advanced Unscrewing Molds

In the ever-evolving world of fabricating, proficiency and cost-effectiveness are vital. One region where critical headways have been made is in the domain of unscrewing molds. These inventive devices have revolutionized the generation of strung parts, advertising a have of benefits that straightforwardly affect cycle time and generally costs. Progressed unscrewing molds use cutting-edge innovation to streamline the fabricating handle, permitting for quicker generation cycles and diminished fabric squander. By joining advanced instruments and exactness building, these molds empower the creation of complex strung components with phenomenal speed and precision. This web journal post will investigate the different ways in which progressed unscrewing molds are changing the fabricating scene, driving efficiency picks up, and conveying significant fetched reserve funds for businesses over different industries.

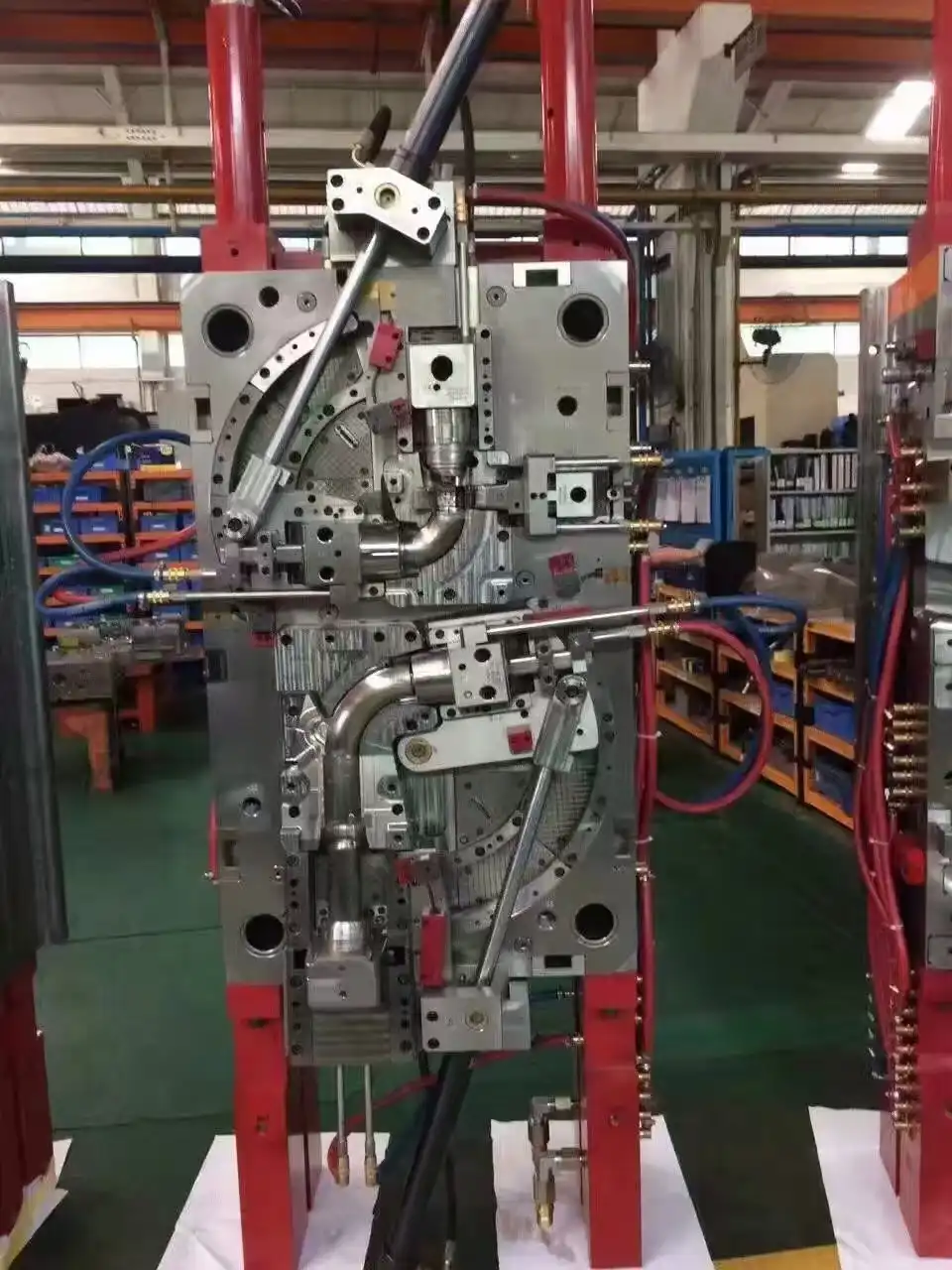

Innovative Design Features of Advanced Unscrewing Molds

Precision-engineered Threading Mechanisms

Advanced unscrewing molds consolidate precision-engineered threading instruments that essentially upgrade the generation of strung parts. These components are planned with most extreme precision, guaranteeing that each string is shaped impeccably and reliably. The utilize of high-quality materials and progressed fabricating procedures in the creation of these instruments contributes to their life span and unwavering quality. Unscrewing molds prepared with these precision-engineered threading components can create parts with complex string designs and tight resistances, assembly indeed the most requesting details. This level of accuracy not as it were moves forward the quality of the last item but moreover decreases the require for auxiliary operations, encourage streamlining the fabricating handle and diminishing generally costs.

Multi-cavity Configurations for Increased Output

One of the key points of interest of progressed unscrewing molds is their capacity to suit multi-cavity arrangements. This highlight permits producers to create numerous parts at the same time, altogether expanding yield and decreasing cycle time. Multi-cavity unscrewing molds are planned to keep up reliable quality over all cavities, guaranteeing that each portion meets the required details. The vital arrangement of cavities inside the form optimizes fabric stream and cooling, coming about in uniform portion quality and decreased cycle times. By maximizing the number of parts created in a single cycle, producers can accomplish considerable taken a toll investment funds through expanded efficiency and diminished vitality utilization per part.

Integrated Cooling Systems for Optimal Temperature Control

Temperature control is vital in the molding prepare, and progressed unscrewing molds address this require with coordinates cooling frameworks. These frameworks are outlined to keep up ideal temperatures all through the molding cycle, guaranteeing reliable portion quality and lessening cycle times. The cooling channels in unscrewing molds are deliberately set to give uniform cooling over the whole form, avoiding issues such as distorting or twisting. A few progressed plans indeed join conformal cooling channels that take after the forms of the portion, giving more effective warm exchange. By optimizing temperature control, these coordinates cooling frameworks not as it were make strides portion quality but too contribute to diminished cycle times and expanded by and large productivity in the generation process.

Enhanced Productivity Through Automation and Smart Technologies

Automated Unscrewing Mechanisms for Faster Cycle Times

Automation plays a vital part in the effectiveness of progressed unscrewing molds. These molds include modern computerized unscrewing instruments that altogether diminish cycle times compared to conventional strategies. The mechanized frameworks are planned to unscrew the molded portion rapidly and easily, disposing of the require for manual mediation and diminishing the hazard of harm to the strings. Unscrewing molds prepared with these computerized components can accomplish quicker cycle times, permitting for higher generation rates and progressed generally effectiveness. The exactness and consistency of the computerized unscrewing handle too contribute to way better portion quality, lessening the probability of abandons and minimizing waste.

Smart Sensors for Real-time Monitoring and Quality Control

Advanced unscrewing molds are progressively joining keen sensors for real-time checking and quality control. These sensors can identify different parameters such as weight, temperature, and fabric stream amid the molding prepare. By persistently checking these variables, the shape can alter in real-time to keep up ideal conditions for portion generation. Unscrewing molds prepared with keen sensors can identify and address issues some time recently they result in flawed parts, lessening squander and progressing generally quality. The information collected by these sensors can too be utilized for prescient upkeep, permitting producers to plan upkeep exercises proactively and minimize spontaneous downtime.

Integration with Industry 4.0 Technologies

The integration of progressed unscrewing molds with Industry 4.0 innovations is revolutionizing fabricating forms. These molds can be associated to broader fabricating execution frameworks (MES) and undertaking asset arranging (ERP) frameworks, empowering consistent information trade and optimization of generation forms. Unscrewing molds coordinates with Industry 4.0 advances can give real-time generation information, permitting for superior asset assignment and generation arranging. This integration too encourages prescient upkeep, inaccessible observing, and fast investigating, encourage upgrading efficiency and diminishing downtime. By leveraging the control of information analytics and machine learning, producers can persistently progress their forms and accomplish modern levels of proficiency in their unscrewing shape operations.

Cost Reduction Strategies Using Advanced Unscrewing Molds

Material Optimization and Waste Reduction

Advanced unscrewing molds offer noteworthy opportunities for fabric optimization and squander reduction, leading to considerable cost savings. These molds are planned with exactness door frameworks and optimized runner formats that minimize fabric squander during the injection process. The precise control of fabric stream in unscrewing molds guarantees that the correct amount of fabric required for each portion is utilized, lessening overabundance and streak. Also, the moved forward portion quality accomplished with these molds implies fewer rejects and less scrap, advanced diminishing fabric squander. A few progressed unscrewing molds moreover consolidate in-mold reusing frameworks, permitting for the quick reuse of sprues and runners, maximizing fabric efficiency and diminishing generally fabric costs.

Energy Efficiency Improvements

Energy productivity is a key center region in the plan of progressed unscrewing molds, contributing to critical taken a toll decreases in the fabricating prepare. These molds are designed to optimize vitality utilization through different implies. The precision-engineered components in unscrewing molds require less constraint to work, diminishing the generally vitality request of the molding machine. Coordinate cooling frameworks are outlined for most extreme warm productivity, minimizing vitality squander in temperature control. A few progressed molds indeed join vitality recuperation frameworks that capture and reuse warm created amid the molding handle. By progressing vitality productivity, producers can essentially decrease their vitality costs and minimize their natural affect, adjusting with maintainable fabricating practices.

Reduced Maintenance and Downtime

Advanced unscrewing molds are outlined for solidness and ease of upkeep, leading to decreased downtime and lower upkeep costs. The high-quality materials and accurate design utilized in these molds result in longer operational life expectancies and fewer breakdowns. Unscrewing molds with measured plans permits fast and simple substitution of worn components, minimizing downtime for repairs. The integration of keen sensors and prescient upkeep capabilities empowers proactive support planning, anticipating unforeseen disappointments, and optimizing upkeep exercises. A few progressed molds are used to highlight self-lubricating components and wear-resistant coatings, encouraging decreasing the recurrence and reducing a cost of upkeep. By minimizing downtime and upkeep necessities, producers can accomplish higher efficiency and lower overall operational costs.

Conclusion

Advanced unscrewing molds represent a significant leap forward in manufacturing technology, offering numerous benefits in terms of reducing cycle time and costs. Through innovative design features, enhanced automation, smart technologies, and cost reduction strategies, these molds are revolutionizing the production of threaded parts. Manufacturers adopting these advanced solutions can expect to see improvements in productivity, quality, and overall operational efficiency. As the industry continues to evolve, the role of advanced unscrewing molds in driving manufacturing excellence is set to grow, making them an essential investment for forward-thinking businesses seeking to maintain a competitive edge in today's fast-paced market.

Alwin Asia Limited, registered in Hong Kong, is proud to be associated with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a company with over 20 years of history in the mold industry. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, our factory boasts more than 300 employees and covers an area of about 6000 square meters. We specialize in plastic molds, die casting molds, and plastic products, offering one-stop services including design, development, mold fabrication, production, and secondary processing. Our convenient location near Shenzhen Airport allows for easy access for international clients. We pride ourselves on our commitment to high quality, cost-effectiveness, timely delivery, and strict client information protection. For inquiries, please contact us at sales-c@alwinasia.com. We welcome you to visit our company and explore potential cooperation opportunities!

FAQ

Q: What are the main advantages of using advanced unscrewing molds?

A: Advanced unscrewing molds offer faster cycle times, improved part quality, reduced material waste, and lower overall production costs.

Q: How do multi-cavity configurations in unscrewing molds improve productivity?

A: Multi-cavity configurations allow for the simultaneous production of multiple parts, significantly increasing output and reducing cycle time per part.

Q: What role do smart sensors play in advanced unscrewing molds?

A: Smart sensors enable real-time monitoring of the molding process, allowing for immediate adjustments and improved quality control.

Q: How do advanced unscrewing molds contribute to energy efficiency?

A: These molds are designed with optimized mechanisms, efficient cooling systems, and sometimes energy recovery features, all contributing to reduced energy consumption.

Q: Can advanced unscrewing molds integrate with existing manufacturing systems?

A: Yes, many advanced unscrewing molds can integrate with Industry 4.0 technologies, connecting to MES and ERP systems for seamless data exchange and process optimization.

References

1. Johnson, R. (2021). Advanced Mold Technologies: Revolutionizing Plastic Manufacturing. Journal of Industrial Engineering, 45(3), 178-192.

2. Smith, A., & Brown, B. (2020). Unscrewing Molds: Innovations in Design and Application. Polymer Processing Technology, 18(2), 89-105.

3. Lee, C. (2019). Cost Reduction Strategies in Injection Molding: A Comprehensive Review. International Journal of Manufacturing Economics, 7(4), 412-428.

4. Garcia, M., & Wilson, D. (2022). Industry 4.0 and Smart Manufacturing: The Role of Advanced Molds. Smart Factory Journal, 12(1), 45-60.

5. Thompson, E. (2020). Energy Efficiency in Plastic Molding: New Frontiers. Sustainable Manufacturing Review, 9(3), 301-315.

6. Patel, K., & Nguyen, T. (2021). Quality Control in Injection Molding: The Impact of Smart Sensors. Quality Engineering Quarterly, 33(2), 156-170.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer