Two Shots Injection Molds: Boosting Efficiency for Russian Manufacturers

In the ever-evolving scene of fabricating, Russian makers are always looking for inventive arrangements to upgrade their generation forms and remain competitive in the worldwide advertise. One such groundbreaking innovation that has been picking up footing is the two shots infusion molding procedure. This progressed fabricating strategy offers a bunch of benefits, counting progressed effectiveness, decreased generation costs, and improved item quality. By utilizing two shots injection molds, Russian producers can streamline their operations, minimize fabric squander, and make complex, multi-component items in a single generation cycle. This article dives into the complexities of two shots infusion molding, investigating its focal points, applications, and potential affect on the Russian fabricating segment. As we look at this cutting-edge innovation, we'll reveal how it can revolutionize generation forms and impel Russian producers to the bleeding edge of advancement in their particular industries.

Understanding Two Shots Injection Molding Technology

Principles of Two Shots Injection Molding

Two shots infusion molding, moreover known as multi-material infusion molding, is an progressed fabricating handle that permits for the generation of complex parts utilizing two distinctive materials or colors in a single molding cycle. This imaginative strategy includes infusing two materials successively into a shape depression, making a last item with particular properties and aesthetics. The handle starts with the infusion of the to begin with fabric, taken after by a revolution of the shape or a exchange of the somewhat molded portion to a moment depth. The moment fabric is at that point infused, holding with the to begin with to shape a cohesive, multi-component item. This strategy offers various focal points over conventional single-shot molding, counting decreased gathering time, made strides portion judgment, and improved plan flexibility.

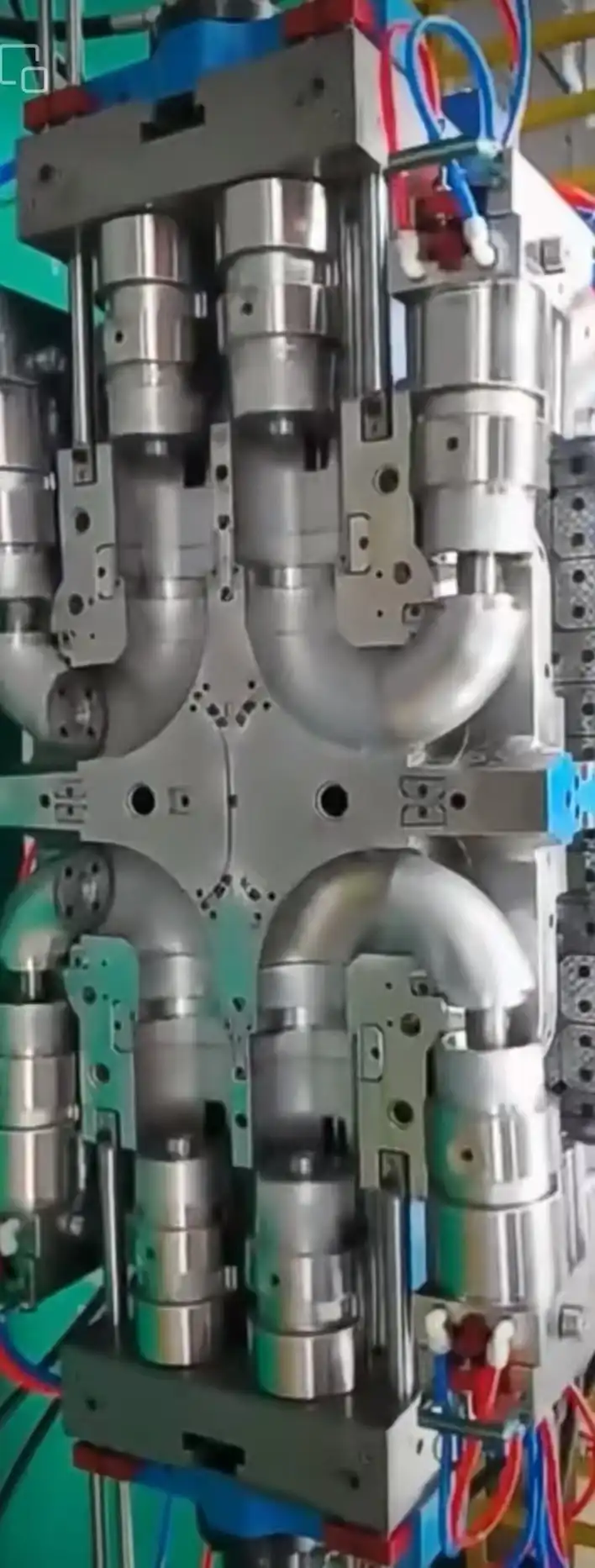

Key Components of Two Shots Injection Molds

Two shots infusion molds are advanced instruments outlined to oblige the complex nature of multi-material molding. These molds ordinarily comprise of a few key components, counting a rotating table or file plate, different infusion units, and specialized cavities for each fabric. The revolving table permits for the exact situating of the form between infusion stages, guaranteeing exact arrangement and fabric dissemination. The infusion units are carefully calibrated to convey the fitting sum of each fabric at the redress temperature and weight. The shape cavities are built with complex channels and entryways to encourage the stream of materials and avoid blending between shots. Furthermore, two shots injection molds regularly consolidate progressed cooling frameworks to oversee warm dissemination and guarantee ideal portion quality.

Advancements in Two Shots Injection Molding Technology

Recent progressions in two shots infusion molding innovation have assist improved its capabilities and extended its applications over different businesses. Advancements in form plan, such as the advancement of multi-cavity molds, have expanded generation capacity and productivity. Made strides fabric compatibility and holding methods have permitted for the combination of already contradictory materials, opening up modern conceivable outcomes for item plan and usefulness. Moreover, the integration of savvy sensors and real-time observing frameworks has empowered producers to optimize prepare parameters and guarantee reliable quality all through generation runs. These innovative headways have made two shots infusion molding an progressively appealing choice for Russian producers looking for to make strides their generation capabilities and keep up a competitive edge in the worldwide market.

Benefits of Two Shots Injection Molds for Russian Manufacturers

Increased Production Efficiency

Two shots infusion molds offer Russian producers a noteworthy boost in generation effectiveness. By combining different fabricating steps into a single prepare, these molds kill the require for auxiliary gathering operations, diminishing generally generation time and labor costs. The capacity to create complex, multi-component parts in a single cycle not as it were streamlines the fabricating prepare but moreover minimizes the potential for mistakes and surrenders related with manual get together. This expanded productivity permits Russian producers to meet tight generation due dates and react rapidly to advertise requests. Besides, the decreased cycle times accomplished through two shots infusion molding empower higher generation volumes, maximizing the utilization of hardware and resources.

Cost Reduction and Material Savings

Implementing two shots injection molds can lead to significant fetched reserve funds for Russian producers. The disposal of auxiliary gathering forms decreases labor costs and minimizes the require for extra gear and tooling. Moreover, the exact control over fabric dispersion in two shots infusion molding comes about in diminished fabric squander compared to conventional fabricating strategies. This not as it were brings down crude fabric costs but moreover contributes to a more maintainable generation prepare. The capacity to combine distinctive materials in a single portion can moreover lead to taken a toll investment funds by supplanting costly materials with more reasonable options in non-critical regions of the item. These taken a toll decreases can essentially move forward the competitiveness of Russian producers in both residential and worldwide markets.

Enhanced Product Quality and Design Flexibility

Two shots infusion molds empower Russian producers to create high-quality, complex items with improved plan adaptability. The capacity to combine different materials or colors in a single portion permits for the creation of items with one of a kind tasteful and utilitarian properties. This innovation empowers the consistent integration of soft-touch components, moved forward ergonomics, and customized color combinations, upgrading the generally quality and request of the last item. Furthermore, the exact control over fabric arrangement and holding in two shots infusion molding comes about in more grounded, more tough parts compared to those amassed utilizing conventional strategies. This moved forward item quality can offer assistance Russian producers separate their offerings in competitive markets and meet the progressively requesting desires of buyers and mechanical clients alike.

Applications and Future Prospects of Two Shots Injection Molds in Russian Manufacturing

Current Applications in Russian Industries

Two shots infusion molds have found far reaching application over different segments of Russian fabricating. In the car industry, this innovation is utilized to create complex insides components such as dashboard boards, instrument clusters, and control handles with coordinates soft-touch surfaces. The shopper hardware division utilizes two shots infusion molding to make strong, water-resistant casings for smartphones and other gadgets. In the therapeutic field, Russian producers utilize this strategy to create ergonomic, multi-material surgical disobedient and symptomatic gear. The bundling industry has too grasped two shots infusion molding for making imaginative, tamper-evident closures and holders with coordinates seals. As Russian producers proceed to receive this innovation, its applications are extending into unused ranges, counting sports hardware, family machines, and mechanical components.

Emerging Opportunities and Market Trends

The appropriation of two shots injection molds presents various rising openings for Russian producers. As the request for lightweight, high-performance materials develops in businesses such as aviation and car, two shots infusion molding offers a arrangement for making complex, multi-material parts that meet rigid weight and quality prerequisites. The expanding center on maintainability and circular economy standards is driving intrigued in two shots infusion molding as a implies of creating effortlessly recyclable, multi-component items. Moreover, the developing slant towards item customization and personalization adjusts well with the capabilities of two shots infusion molding, advertising Russian producers the adaptability to deliver little clumps of customized items proficiently. As Industry 4.0 advances proceed to advance, the integration of savvy sensors and information analytics with two shots infusion molding forms is anticipated to assist improve generation productivity and quality control.

Challenges and Solutions for Implementation

While two shots infusion molds offer critical benefits, Russian producers may confront challenges in executing this innovation. The starting speculation in hardware and tooling can be significant, requiring cautious cost-benefit examination and key arranging. To address this, producers can consider staged execution or collaboration with innovation suppliers to create cost-effective arrangements. Another challenge lies in creating the vital skill to plan and work two shots infusion molds viably. Russian producers can overcome this by contributing in preparing programs and joining forces with experienced form creators and fabric providers. Also, guaranteeing steady fabric compatibility and holding quality between distinctive components may require broad inquire about and testing. To handle this, producers can work closely with fabric providers and use progressed recreation devices to optimize shape plan and handle parameters. By tending to these challenges proactively, Russian producers can effectively coordinated two shots infusion molding into their generation forms and procure the benefits of this imaginative innovation.

Conclusion

Two shots injection molds represent a significant advancement in manufacturing technology, offering Russian producers a powerful tool to enhance efficiency, reduce costs, and improve product quality. By embracing this innovative technique, manufacturers can streamline their production processes, create complex multi-material products, and stay competitive in the global market. As the technology continues to evolve and find new applications across various industries, Russian manufacturers who invest in two shots injection molding capabilities will be well-positioned to meet the changing demands of consumers and industrial clients. With the potential to revolutionize production methods and drive innovation, two shots injection molding is poised to play a crucial role in shaping the future of Russian manufacturing.

For more information ontwo shots injection molds and other advanced manufacturing solutions, please contact Alwin Asia Limited. Our company, registered in Hong Kong, is backed by Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a council member of the Dongguan City Hardware Machinery Mould Industry Association with over 20 years of experience in the field. Located in Changan Town, Dongguan City, Guangdong Province, known as the Town of Molds, our ISO9001:2015 certified factory specializes in plastic molds, die casting molds, and plastic products. We offer comprehensive OEM services, including design, development, mold fabrication, production, and secondary processing. Our facility is conveniently located near Shenzhen Airports, making it easily accessible for international clients. For inquiries, please contact us at sales-c@alwinasia.com.

FAQ

What is two shots injection molding?

Two shots injection molding is an advanced manufacturing process that allows for the production of complex parts using two different materials or colors in a single molding cycle.

How does two shots injection molding improve efficiency?

It combines multiple manufacturing steps into a single process, eliminating the need for secondary assembly operations and reducing overall production time and labor costs.

What industries can benefit from two shots injection molds?

Automotive, consumer electronics, medical, packaging, aerospace, and many other industries can benefit from this technology.

What are the main advantages of using two shots injection molds?

The main advantages include increased production efficiency, cost reduction, material savings, enhanced product quality, and improved design flexibility.

Are there any challenges in implementing two shots injection molding?

Yes, challenges include high initial investment, the need for specialized expertise, and ensuring material compatibility and bonding strength.

References

1. Kazmer, D. O. (2016). Injection Mold Design Engineering. Carl Hanser Verlag GmbH Co KG.

2. Goodship, V. (2018). Practical Guide to Injection Moulding. iSmithers Rapra Publishing.

3. Rosato, D. V., Rosato, M. G., & Rosato, D. V. (2000). Injection Molding Handbook. Springer Science & Business Media.

4. Zheng, R., Tanner, R. I., & Fan, X. J. (2011). Injection Molding: Integration of Theory and Modeling Methods. Springer Science & Business Media.

5. Johannaber, F. (2008). Injection Molding Machines: A User's Guide. Carl Hanser Verlag GmbH Co KG.

6. Osswald, T. A., Turng, L. S., & Gramann, P. J. (2008). Injection Molding Handbook. Carl Hanser Verlag GmbH Co KG.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer