What Are Medical Parts Manufacturing Quality Standards?

When it comes to safety, dependability, and accuracy, the medical parts business is one of the most important ones. There are very strict quality standards in this field because they have a direct effect on the health and well-being of patients. In order to make sure that medical parts meet strict requirements for performance, sturdiness, and biocompatibility, these standards include a lot of rules, guides, and best practices. During the creation, production, and marketing stages of everything from surgery tools to internal devices, each part must meet strict quality control standards. As the basis for trust in medical technology, these standards are important for everyone to understand, including makers, healthcare workers, and patients. To make sure patients are safe, this piece talks about the main quality standards for making medical parts, how important they are, and how regulatory compliance is changing in the medical device business.

ISO 13485: The Cornerstone of Medical Device Quality Management

Understanding ISO 13485 Requirements

Those who make medical devices must follow the worldwide standard ISO 13485 for their quality control systems. Making sure that medical parts are always made to meet customer and government standards is made possible by this thorough system. Along with research and development, production, storage, delivery, installation, and service, it covers many other parts of the manufacturing process. Following the rules set by ISO 13485 requires manufacturers to set up strong systems for paperwork, risk management, and process evaluation. Making sure you keep records of all the things you do that have to do with quality and doing regular internal checks to find places to improve is something that the standard stresses. Healthcare companies that make parts for hospitals can show they care about quality and safety by following ISO 13485. This boosts their reputation in the global market.

Implementing ISO 13485 in Medical Parts Production

Putting ISO 13485 into practice in the production of medical parts needs a planned method that includes everyone in the company. Manufacturers need to make a quality policy that fits with the requirements of the standard and get the word out to everyone in the company. Setting quality goals, laying out jobs and tasks, and making sure there are enough resources for quality management activities are all part of this. It is important that the process of making medical parts is managed and follows clear steps and processes. At different steps of production, quality control checks should be done to make sure that parts meet the standards. Manufacturers must also set up a way to handle goods that don't meet standards and take corrective and preventative actions. Management reviews must happen on a regular basis to see how well the quality management system is working and to keep pushing for growth in the making of medical parts.

Benefits of ISO 13485 Certification for Medical Parts Manufacturers

Receiving ISO 13485 approval can be very helpful for companies that make medical parts. Providers who are ISO 13485 accepted have an advantage in the global market because many healthcare companies and government agencies expect them to be. When you have this license, it shows that you care about quality and safety, which can make customers trust you more and stay with you longer. Additionally, using ISO 13485 can help businesses be more productive and spend less because it promotes an organized way of managing quality. Part of the norm is managing risk. Things makers can find and fix problems before they affect the quality of their work or the safety of their patients. Additionally, getting ISO 13485 approval can help people who make medical products that are used in other countries follow the rules more easily. When medical part makers follow this standard, they have a better reputation and will be more successful in the long run.

FDA Regulations for Medical Parts Manufacturing

Overview of FDA Quality System Regulation (QSR)

If a company makes medical goods for the U.S. market, they have to follow 21 CFR Part 820, also known as the FDA Quality System Regulation (QSR). These are very important rules. Quality management systems make sure that medical devices are safe and work well. This law has rules about how to set up and keep up these systems. The QSR talks about a lot of different parts of the industrial process. It includes controls for design, controls for output and process, correction and preventative actions (CAPA), and keeping records. Firm quality control measures must be used by makers to ensure that medical parts meet the requirements and work as planned. The FDA checks in on businesses on a regular basis to make sure they are following the QSR. If companies don't, it could cause bad things to happen, like having to return goods and follow new rules.

FDA Good Manufacturing Practices (GMP) for Medical Parts

There are rules for making medical parts that are very important, and one of them is called Good Manufacturing Practices (GMP). Making sure that medical products are always made and checked to make sure they meet the quality standards needed for their purpose is what these operations do. As part of GMP standards, facilities must be designed and maintained, tools must be qualified, staff must be trained, and processes must be proven to work. During the whole process of making medical parts, companies that follow GMP must use strict quality control measures. While doing this, make sure the areas are always clean and under control, keep the tools in good shape, and set up strong ways to keep records. Pharmaceutical companies can make sure that medical parts are safe for patients and work well by following GMP standards.

FDA Premarket Notification (510(k)) Process for Medical Parts

This process is also known as FDA Premarket Notification (510(k)). It's an important legal road for many companies that make medical parts. The people who make these products have to show that they are mostly the same in terms of safety and effectiveness as a reference gadget that is already on the market. Sometimes this means telling a lot of details about the medical part, like how it was made, what it will be used for, and what it is designed for. To back up their 510(k) application, producers have to include a lot of details, like risk assessments and success figures. This information is used by the FDA to check if the new medical part is safe and works well. Manufacturers who want to sell new medical parts in the U.S. must be able to get through the 510(k) process. This is because it lets the government give the all-clear without needing a more thorough premarket review.

European Medical Device Regulation (MDR) and CE Marking

Understanding the European MDR Requirements

In the European Union, there are a lot of rules about how medical gadgets are made, sold, and checked after they have been bought. This set of rules is known as the European Medical Device Regulation (MDR). Medtech businesses that want to sell their goods in Europe need to know and follow the MDR. This law cares a lot about the safety of the product, scientific review, and being able to keep track of the tool its whole life. It is important for companies that make medical parts to have strong quality control systems, do thorough risk assessments, and keep a lot of expert papers. Better oversight after the market is closed because of the MDR. This means the people who made the things have to check on how safe and well they work after they've been sold. Meeting the MDR standards shows that you are serious about making high-quality medical parts that meet the strict safety and performance standards of the EU.

CE Marking Process for Medical Parts

Manufacturers of medical parts that want to sell their goods in the European Economic Area (EEA) need to get CE marking. As part of the process, proof must be given that all EU health, safety, and environmental protection rules are being followed. This is usually done through conformity assessment processes for medical parts, which can include type study, quality assurance, and product proof. Manufacturers must put together a technical file with specific information about how the medical part was designed, how it was made, and what it is meant to be used for. Risk management is an important part of getting a CE mark, and makers have to find and fix any problems that might be caused by their goods. Manufacturers can put the CE mark on their medical parts once compliance is proven. This means that the parts meet all EU standards and can be sold easily in the EEA.

Post-Market Surveillance Under the European MDR

A key part of the European MDR that medical device makers must deal with is post-market monitoring. As this process goes on, data on how well and safely medical gadgets work after they have been sold are constantly collected and analyzed. For medical parts, this could mean keeping an eye on what customers say, looking at data on complaints, and doing regular safety checks. It is expected of manufacturers to set up a full post-market tracking system that lets possible safety or performance problems be found early on. This method should have ways to report major events and take appropriate steps for field safety when they are needed. Periodic safety update reports (PSURs) are another idea that comes from the MDR. These require device makers to regularly look at the risks and benefits of their products. Manufacturers of medical parts can make sure that their goods are safe and successful in real life by keeping up strong post-market tracking practices.

Conclusion

Safety, effectiveness, and dependability of medical equipment depend on high standards for making medical parts. The European MDR, ISO 13485, and FDA rules all provide a complete system for quality control throughout the entire duration of a product. Using these guidelines, companies can show they are dedicated to quality and earn the trust of both healthcare professionals and customers. As regulations and technology change, it is important for companies that make medical parts to stay up to date and make changes to their quality control systems as needed. High-quality standards in the production of medical parts are not only required by law, but they are also morally right and have a direct effect on patient results and general health.

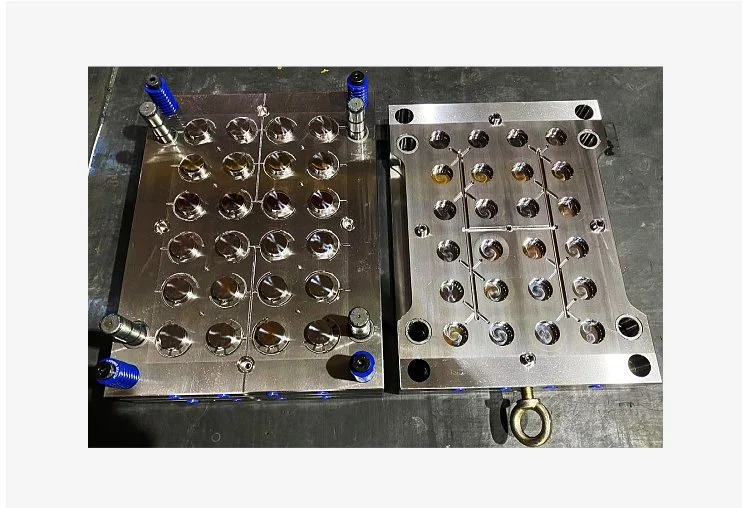

For those seeking a reliable partner in medical parts manufacturing, Alwin Asia Limited, registered in Hong Kong, offers exceptional expertise and quality assurance. Our manufacturing facility, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., has been a trusted name in the industry since 1993. With over 300 employees and 6000 square meters of manufacturing space, we specialize in plastic molds, die casting molds, and plastic products. Our ISO9001:2015 certification underscores our commitment to quality. Located in Chang'an Town, Dongguan City, we are conveniently situated near Shenzhen airports, making site visits easy for our international clients. For inquiries, please contact us at sales@alwinasia.com. We look forward to the opportunity to serve your medical parts manufacturing needs with our decades of experience and dedication to quality.

FAQ

Q: What is ISO 13485, and why is it important for medical parts manufacturing?

A: ISO 13485 is an international standard for quality management systems in medical device manufacturing. It's important because it ensures consistent production of safe and effective medical parts that meet regulatory requirements.

Q: How does the FDA regulate medical parts manufacturing in the United States?

A: The FDA regulates medical parts manufacturing through the Quality System Regulation (QSR), Good Manufacturing Practices (GMP), and the Premarket Notification (510(k)) process to ensure product safety and efficacy.

Q: What is CE marking, and why is it necessary for medical parts in Europe?

A: CE marking is a certification indicating that a medical part complies with EU health, safety, and environmental protection standards. It's necessary for selling medical devices in the European Economic Area.

Q: What are the key differences between ISO 13485 and FDA QSR?

A: While both focus on quality management, ISO 13485 is an international standard, whereas FDA QSR is specific to the U.S. market. FDA QSR has additional requirements for design controls and complaint handling.

Q: How does post-market surveillance benefit medical parts manufacturers?

A: Post-market surveillance helps manufacturers detect and address potential safety issues or performance problems early, ensuring ongoing product safety and effectiveness in real-world use.

References

1. International Organization for Standardization. (2016). ISO 13485:2016 Medical devices — Quality management systems — Requirements for regulatory purposes.

2. U.S. Food and Drug Administration. (2020). Quality System (QS) Regulation/Medical Device Good Manufacturing Practices.

3. European Commission. (2017). Regulation (EU) 2017/745 of the European Parliament and of the Council on medical devices.

4. World Health Organization. (2003). Medical Device Regulations: Global Overview and Guiding Principles.

5. Global Harmonization Task Force. (2004). Quality Management Systems - Process Validation Guidance.

6. Association for the Advancement of Medical Instrumentation. (2019). AAMI TIR45:2019 Guidance on the use of AGILE practices in the development of medical device software.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer