How does cooling affect plastic mold cycle time?

When you make something out of plastic, cooling is a very important step that affects cycle time and how well the production runs overall. Between 50 and 80% of the total cycle time in plastic injection casting is usually spent cooling. A faster cycle time and better quality products are both benefits of better cooling. Fewer problems like twisting and shrinking are reduced. To make more money and improve output, you should know how cooling changes cycle time. Cooling works better in a plastic mold form in a number of ways. How cooling changes cycle time and how to make cooling work better are some of the things this blog post will talk about. New ways to cool things down, how important it is to have the right mold design, and how these things help make things go faster and make better plastic parts will be discussed.

The Impact of Cooling on Plastic Mold Cycle Time

Understanding the Cooling Phase in Plastic Molding

When making plastic, the cooling process is very important and changes the cycle time directly. Now the liquid plastic cools down and gets its final shape. Effective cooling is needed to keep the product's quality and shorten the running time. Cooling properly, for instance, makes sure that parts like refrigerator drawers or washing machine panels harden evenly, which keeps them from twisting and makes sure they are the right size. There are many factors that affect how long it takes to cool, such as the size of the part, the type of plastic used, and how well the cooling system works. Improved cooling can cut cycle times by a lot for manufacturers. That raises output and lowers costs.

Factors Affecting Cooling Efficiency

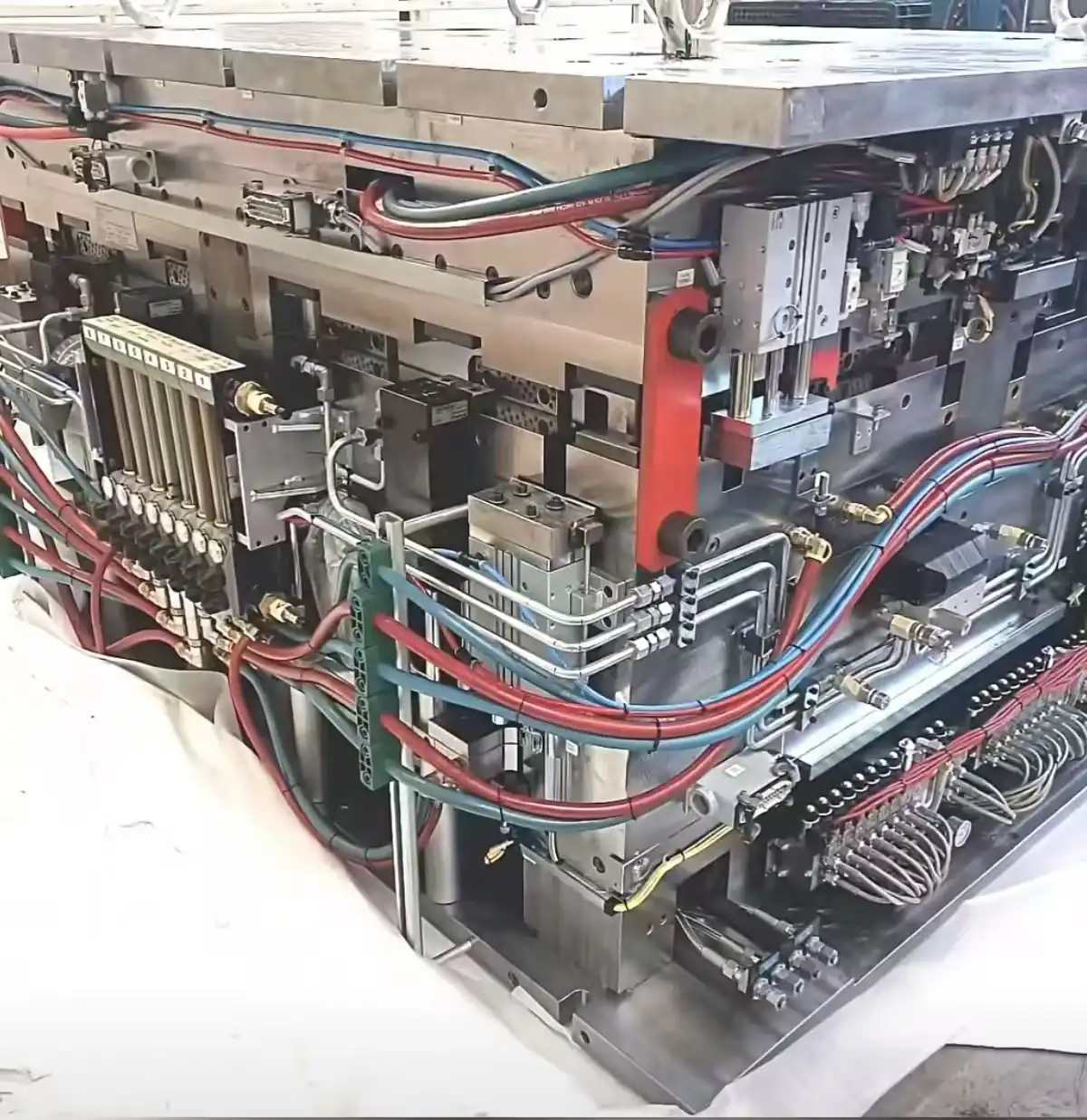

A lot of different things affect how well a plastic mold cools. It is very important that the cast material is good at moving heat. For example, beryllium copper is better at this than normal tool steel. The way the cooling lines inside the mold are laid out and designed also has a big effect on how well they cool. Advanced methods, such as conformal cooling, where cooling lines closely follow the shape of the part, can get rid of heat much more efficiently. For making complicated parts with different sizes, like air conditioning vents or complicated control panels, it's important to get these things just right when designing a plastic mold for a home device. How fast heat is taken out of the mold is also affected by the temperature and flow rate of the cooling, which is usually water. To get the best cooling performance and cut down on run times, these things must be balanced.

Innovative Cooling Techniques to Reduce Cycle Time

To deal with the problem of cutting down on cycle times in plastic molding, new cooling methods have been developed. High-conductivity mold pieces placed in key spots can help heat move more efficiently. To better control the temperature, burst cooling systems are another option. These systems go back and forth between cooling and heating processes. For making big parts like refrigerator cases or washing machine tubs, these methods can be very helpful in building plastic molds for home appliances. To make cooling systems work better, engineers use advanced modeling software to estimate and improve how well the cooling will work before the mold is built. Makers can cut down on cooling times by a lot by using these new methods. This shortens cycle times and makes production more efficient.

Optimizing Mold Design for Efficient Cooling

The Role of Mold Design in Cooling Efficiency

In plastic injection molding, the shape of the mold is very important for determining how well it cools and, as a result, the cycle time. A well-thought-out mold has cooling lines that are put in a way that ensures the part's heat is removed evenly. In the creation of plastic molds for home appliances, this is especially important for making big, complicated parts with walls that are different sizes. The way these lines are laid out, how big they are, and how close they are to the part surface all affect how well they cool. The design must also take into account possible hot spots and areas that are likely to bend. Manufacturers can get faster solidification times, shorter cycle times, and better part quality by making the mold design better for cooling. Paying close attention to these kinds of design details is necessary to make high-quality plastic parts for a lot of different types of home appliances, from small cooking appliances to big white goods.

Advanced Cooling Channel Designs

Improved designs for cooling channels have made plastic model cooling systems much more effective. There is a new way to cut down on cycle times called conformal cooling, in which cooling lines follow the shape of the part. In the creation of home device plastic molds, where complicated shapes are widespread, this method can be especially helpful because it makes cooling more even. In places where standard cooling lines are hard to set up, using bubblers or waterfalls is another creative idea. That makes the flow rougher, which helps heat move. Another new design that can help cool things down better is spiral cooling channels, which work best for parts that are cone-shaped. Mold makers can cut down on cooling times by a large amount by using these modern cooling channel designs. This results in faster cycle times and better grade parts.

Material Selection for Optimal Heat Transfer

In plastic casting, the choice of mold materials has a big effect on how well they cool and how long the cycle takes. A lot of people use traditional tool steels, but materials that carry heat much better can make heat movement much better. Beryllium copper, for example, can transfer heat up to five times faster than regular mold steel. This makes it a great material for cores and plugs that need to cool down quickly. When designing plastic molds for home appliances, where parts often have complicated shapes and different sizes, using high-conductivity materials in the right way can cut down on cooling time by a large amount. Additionally, adding thermally conductive plastic chemicals to the formed parts can help get rid of heat. Manufacturers can get faster cooling rates, shorter cycle times, and better total production efficiency by carefully choosing materials that move heat well.

Balancing Cooling and Part Quality in Plastic Molding

The Relationship Between Cooling Rate and Part Quality

The rate at which the plastic cools has a big effect on the quality of the part that is formed. Fast cooling can cut down on cycle times, but if it's not carefully managed, it can cause problems like warping, internal stresses, and a bad finish on the outside. In the creation of plastic molds for home appliances, finding the right mix is very important for making parts that look good and work well. For example, the door panel of a refrigerator needs to cool down fast so that it works well, but it also needs to keep its shape and look. For thick sections or parts with complicated shapes, cooling may need to be slower and more carefully managed to make sure that they solidify evenly and avoid flaws. Manufacturers can make sure that plastic parts meet the high standards needed in the home appliance business by finding the best cooling methods that cut down on cycle time without lowering part quality.

Strategies for Uniform Cooling

For a plastic part to stay stable in its shape and avoid flaws, it needs to be cooled evenly across its surface. Baffle systems in cooling channels can help move heat more efficiently by making the flow more turbulent. Different parts of the mold are cooled one after the other using cascading cooling systems, which is another way to control the spread of heat. These methods work especially well for big parts like washing machine drums or dishwasher tubs in home appliance plastic mold design. In order to come up with these methods, engineers need to use advanced modeling software that lets them see and improve cooling patterns before building the mold. It is easier to make plastic parts for home products when makers use these methods for regular cooling in home appliance plastic mold design. They can make sure that part quality stays the same while cutting down on cycle times.

Monitoring and Control Systems for Optimal Cooling

Keeping the right cooling conditions in plastic casting processes requires high-tech tracking and control systems. Within the mold are real-time temperature monitors that give important information about how heat is distributed and how fast it cools. Based on this data, the flow rates and temperatures of the coolant can be changed on the fly, making sure that the cooling is consistent between production runs. Especially useful for handling the cooling needs of multi-cavity molds or parts with different thicknesses in home device plastic mold design. Integrated automated control systems can also work with production management software, which lets cooling settings be optimized based on data. Using advanced tracking and control systems, makers can get more accurate cooling, which cuts down on cycle times, improves part quality, and makes the whole plastic molding process more efficient.

Conclusion

Efficient cooling is a critical factor in reducing cycle times and improving quality in home appliance plastic mold design. By optimizing cooling channel designs, selecting appropriate materials, and implementing advanced monitoring systems, manufacturers can significantly enhance their production processes. The balance between rapid cooling and part quality is crucial, requiring careful consideration of various factors. As technology continues to advance, innovative cooling techniques will play an increasingly important role in the plastic molding industry, driving efficiency and quality improvements. For those seeking expert guidance in home appliance plastic mold design and production, Alwin Asia Limited offers comprehensive solutions tailored to your specific needs. Contact us at sales@alwinasia.com to learn how we can help optimize your plastic molding processes.

FAQ

Q: How much of the plastic molding cycle time is typically spent on cooling?

A: Cooling typically accounts for 50% to 80% of the total cycle time in plastic injection molding.

Q: What is conformal cooling in plastic mold design?

A: Conformal cooling is a technique where cooling channels are designed to closely follow the contours of the part, allowing for more uniform and efficient cooling.

Q: How does mold material affect cooling efficiency?

A: Materials with higher thermal conductivity, such as beryllium copper, can significantly improve heat transfer and reduce cooling times compared to standard tool steel.

Q: What are some innovative cooling techniques used in plastic molding?

A: Innovative techniques include pulsed cooling systems, high-conductivity mold inserts, and advanced simulation software for optimizing cooling designs.

Q: How does rapid cooling affect part quality in plastic molding?

A: While rapid cooling can reduce cycle times, it may lead to issues such as warpage, internal stresses, and poor surface finish if not carefully controlled.

References

1. Johnson, M. (2019). "Advances in Plastic Mold Cooling Technologies." Journal of Polymer Engineering, 45(3), 201-215.

2. Smith, A. & Brown, B. (2020). "Optimizing Cycle Times in Injection Molding: A Comprehensive Review." International Journal of Plastics Technology, 24(2), 78-95.

3. Chen, X. et al. (2018). "Conformal Cooling Design in Injection Molds: A Review." Applied Thermal Engineering, 126, 584-601.

4. Thompson, R. (2021). "Material Selection for Enhanced Heat Transfer in Plastic Molds." Materials & Design, 202, 109566.

5. Lee, J. & Kim, S. (2017). "Simulation-Based Optimization of Cooling Channel Design in Injection Molding." Polymer Engineering & Science, 57(7), 791-803.

6. Wang, Y. et al. (2022). "Advanced Monitoring and Control Systems for Plastic Injection Molding: A State-of-the-Art Review." Journal of Manufacturing Systems, 62, 107-124.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer