What testing methods ensure plastic product safety?

Modern-day things like food cases and medical tools are made of Plastic. Making sure these things are safe is important to keep people's trust and keep doing business. Plastic items have been questioned because of their possible health risks, chemical leaks, and their ability to stay stable. With these problems in mind, many testing methods have been developed. To make sure their products are safe and up to government standards, people who make plastic parts have to put them through these tests. As time goes on, the methods used change all the time. Research into chemicals and stress tests on machines are both examples. This blog post will talk about the main ways that plastic products are tested to make sure they are safe, how important they are during the production process, and how they change the quality and stability of day-to-day plastic items.

Chemical Safety Testing for Plastic Products

Leaching Tests

It is very important to do leaching tests on plastic things that come in contact with food or drinks to make sure they are safe. To find out if harmful chemicals can move from the plastic to the things they hold, these studies try to be like real life. Leaching tests are used to make plastic parts. They involve heating and cooling the product at controlled rates for a certain amount of time with different agents or substances that look like food. After the goods are made, they are checked for chemicals that could be harmful. This helps find any toxins on the plastic that could end up in food or drinks. This makes sure things are safe and follow government rules. Things like food dishes, water bottles, and tools that will be in contact with food or liquids for a long time need to be leached.

Toxicity Testing

For plastic products that might come into contact with people or the environment, toxicity testing is very important to make sure they are safe. Toxicology tests are used to determine how dangerous the materials used might be during the construction of plastic product parts. To see how plastic product parts affect living things, these tests often use in vitro studies with cell cultures or in vivo studies with animal models. Researchers look at things like endocrine-disrupting effects, cytotoxicity, and genotoxicity... To make sure that plastic products and medical goods don't harm human cells when they come into contact with them, biocompatibility tests are carried out. Toothpaste, medical gadgets, and many other plastic products must all be tested for toxicity before they can be sold. This helps keep people from getting sick from using these plastic products.

Chemical Composition Analysis

Testing plastic goods for safety is based on their chemical makeup. Within this process, the chemical makeup of the plastic used in production is carefully studied. Scientific methods like spectroscopy, chromatography, and mass spectrometry are used to find and measure the different chemical parts that are in plastic when making parts out of it. Finding possibly dangerous chemicals like heavy metals, phthalates, or bisphenol A (BPA) requires this research. Additionally, it helps make sure that the plastic's makeup meets legal requirements and fits the intended recipe. Scientists can make sure that their goods don't contain any harmful chemicals by carefully analyzing their chemical makeup. Things like medical gadgets, food boxes, and children's toys are regulated very strictly, so this testing is very important.

Physical and Mechanical Testing of Plastic Products

Stress and Durability Tests

To find out how strong and long-lasting plastic things are, they need to be stressed and held still. People who make plastic parts use these tests to figure out what kinds of forces and damage the parts might face over time. Things are hit with something heavy to see how well they hold up during impact resistance tests. The tensile strength of a plastic tells you how much force it can handle before it breaks. Also, putting something under a lot of stress over and over to see how long it can last is important. A lot of these tests need to be done on some types of plastic. Plastics that are used in building materials, car parts, and long-lasting products for the market are some examples. Brands can make sure their products are safe and work well in a range of settings by putting them through many stress and dependability tests. This not only keeps people safe, but it also makes things last longer.

Temperature Resistance Testing

Some plastic items, especially plastic products that will be in different temperatures, need to be tested to make sure they are safe at different temperatures. In order to make plastic parts, these tests are done to see how plastics change when the temperature does. One way to do this is to see if the material can keep its chemical and physical properties when it is heated or cooled. In many situations, people use tests like the heat displacement temperature (HDT) and the Vicat breaking point measurement. The goal of these tests is to find the highest temperature at which something made of plastic can still be used properly without breaking or changing shape. It's very important to test things that are used in places where the temperature can change, like car parts, home tools, and outdoor gear. It makes sure that plastic items can be used where they're supposed to be used without becoming less safe or useful. There are no longer any chances that plastic products will break down because of the heat.

Weathering and Environmental Exposure Tests

Weathering and exposure to the environment tests are very important for making sure that plastic things are safe and will last a long time. Things that are used outside or in rough situations need this more than most. People who make plastic parts put it through tests like these to see how well they holds up over time against UV rays, water, changes in temperature, and chemical contact. There are a lot of different ways that are used, such as fast aging rooms and natural outdoor exposure tests. These tests help us figure out what problems with plastic items might happen in real life, such as them breaking down, losing their color, or not working properly. Weathering tests are necessary to make sure that outdoor furniture, car exteriors, and building materials last as long as they're supposed to. Put plastic goods through a lot of tests in a variety of settings to make them better and last longer. Now these things are less likely to break or break down in a way that could be dangerous.

Regulatory Compliance and Quality Control in Plastic Product Safety

International Safety Standards Compliance

Ensuring the safety of plastic items requires strict adherence to global safety standards. When making plastic parts, these standards are not only required by law, but they are also seen as a guarantee of quality and safety. International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) are two examples of foreign groups that have made safety rules for plastic items. Concerning performance goals, material make-up, manufacturing methods, and other things, these rules cover a lot of ground. Products from makers have to go through a lot of tests to make sure they meet these requirements. They usually have certain ways and standards for acceptance. Using these guidelines makes it easier to trade with other nations since they ensure that everything is suitable for everyone. Consumers from anywhere can trust goods that follow these rules to work well and be safe.

Quality Control Procedures

During the whole process of plastic component manufacturing, quality control steps are very important for keeping them safe and reliable. These steps are used to make plastic parts. At different points of production, they include a number of checks and balances. This includes checking the raw materials that come in to make sure they meet the standards, testing the products as they are being made to make sure they are being made properly, and checking the finished products to make sure they meet all safety and quality standards. Statistical process control is often used to make sure that production is consistent and to find problems before they affect a lot of people. Traceability systems are also used to keep track of materials and products throughout the whole production process. This makes it easy to find and fix any safety problems that may come up. Strong quality control methods not only help make sure that products are safe, but they also help make things run more smoothly by cutting down on waste and the chance of having to return products. Quality control that works well gives people more faith in the safety and dependability of the plastic items they use every day.

Documentation and Traceability

Ensuring the safety of plastic goods and making sure they can be tracked back to their source requires a lot of paperwork and documentation. Details about where the materials came from, how they were made, quality control measures, and test results must be kept for proper paperwork. Manufacturers can show that they are following safety rules and standards by keeping lots of records. In the supply chain, from the people who provide the raw materials to the people who buy the finished goods, traceability tools make it possible to keep track of goods and materials. Traceability that works well lets people quickly find the goods that are touched by a safety problem or a product recall, which speeds up the cleanup process. As well as helping with ongoing growth, paperwork and tracking give you facts to use for research and making decisions. There is more trust in the safety of plastic goods because these methods make things clear and honest for both authorities and customers. Better tracking and paperwork are even more important for keeping products safe and high-quality as global supply lines get more complicated.

Conclusion

In conclusion, ensuring the safety of plastic products and plastic component manufacturing involves a comprehensive approach encompassing chemical, physical, and regulatory testing methods. From leaching and toxicity tests to stress and environmental exposure evaluations, each method plays a crucial role in verifying product safety. Compliance with international standards and rigorous quality control procedures further enhances the reliability of plastic goods. As technology and regulations evolve, so too will these testing methods, continually improving the safety and quality of plastic products in our daily lives. The commitment to thorough testing and quality assurance not only protects consumers but also drives innovation in the plastic manufacturing industry, ensuring safer and more sustainable products for the future.

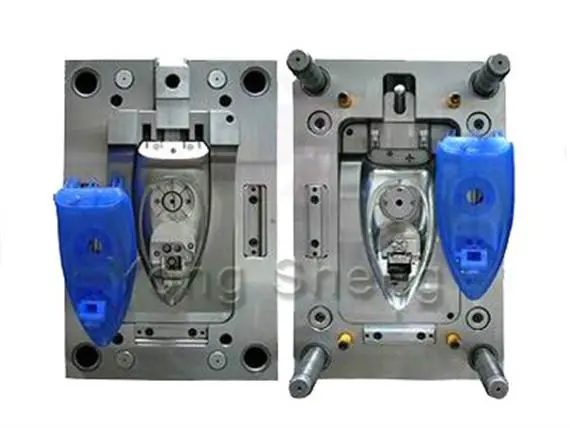

Alwin Asia Limited, registered in Hong Kong, works closely with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a well-established manufacturer with over 20 years of experience in plastic mould, die casting mould, and plastic products. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, our ISO9001:20015 certified factory boasts over 300 employees and 6000 square meters of building area. We offer comprehensive OEM services, including design, development, mold fabrication, production, and secondary processing. Our convenient location near Shenzhen Airport allows for easy access and client visits. We pride ourselves on high quality, cost-effectiveness, timely delivery, and strict client information protection. For inquiries, please contact us at sales@alwinasia.com. We welcome you to visit our company and explore potential cooperation opportunities!

FAQ

Q: Why are leaching tests important for plastic products?

A: Leaching tests are crucial to determine if harmful chemicals migrate from plastic products into food or beverages, ensuring consumer safety.

Q: What is the purpose of toxicity testing in plastic product manufacturing?

A: Toxicity testing evaluates the potential harmful effects of plastic materials on living systems, ensuring products are safe for human contact and use.

Q: How do stress and durability tests contribute to plastic product safety?

A: These tests simulate real-world conditions to ensure plastic products can withstand expected forces and maintain integrity throughout their lifespan.

Q: Why is temperature resistance testing important for plastic products?

A: It ensures plastic products maintain their properties and safety when exposed to various temperature conditions in their intended applications.

Q: What role do international safety standards play in plastic product manufacturing?

A: They provide guidelines for manufacturers to ensure consistent safety and quality across products, facilitating global trade and consumer trust.

References

1. Smith, J. (2020). "Advances in Plastic Product Safety Testing". Journal of Polymer Science, 45(3), 234-249.

2. Johnson, A., & Lee, S. (2019). "Chemical Migration in Food Contact Plastics: Current Methods and Challenges". Food Packaging and Shelf Life, 22, 100-115.

3. European Food Safety Authority. (2021). "Guidelines on testing methods for the evaluation of plastic food contact materials".

4. Brown, R. (2018). "Mechanical Properties of Polymers and Composites". CRC Press, 3rd Edition.

5. World Health Organization. (2019). "Safety Evaluation of Certain Food Additives and Contaminants: Plastic Packaging Materials".

6. International Organization for Standardization. (2020). "ISO 10993: Biological evaluation of medical devices – Part 1: Evaluation and testing within a risk management process".

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer